Nanotechnology/Print version

| This is the print version of Nanotechnology You won't see this message or any elements not part of the book's content when you print or preview this page. |

The Opensource Handbook of Nanoscience and Nanotechnology

Part 1: Introduction

| Navigate |

|---|

| << Prev: Introduction |

| >< Main: Nanotechnology |

| >> Next: Perspective |

|

|

| <<< Prev Part: Main Page |

| >>> Next Part: Seeing Nano |

Introduction to Nanotechnology

Nanotechnology, often shortened to "nanotech," is the study of the control of matter on an atomic and molecular scale. Generally, nanotechnology deals with structures of the size 100 nanometers or smaller in at least one dimension, and involves developing materials or devices within that size. Nanotechnology is very diverse, encompassing numerous fields in the natural sciences.

There has been much debate on the future implications of nanotechnology. Nanotechnology has the potential to create many new materials and devices with a vast range of applications, such as in medicine, electronics and energy production. On the other hand, nanotechnology raises many of the same issues as with any introduction of new technology, including concerns about the toxicity and environmental impact of nanomaterials[1], and their potential effects on global economics, as well as speculation about various doomsday scenarios. These concerns have led to a debate among advocacy groups and governments on whether special regulation of nanotechnology is warranted.

This open source handbook on nanoscience and nanotechnology is divided into the following chapters, each dealing with a particular facet of nanotechnology:

- Chapter 1: INTRODUCTION - A general overview.

- Chapter 2: SEEING 'NANO' - How to observe what is going on on the nanoscale.

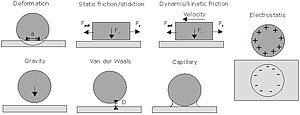

- Chapter 3: PHYSICS -ON THE NANOSCALE - How do things move and what are the important forces on the nanoscale.

- Chapter 4: NANOMATERIALS - The typical nanostructures and their functionality

- Chapter 5: NANOSYSTEMS - Fundamental electronic, optical, mechanical, and fluidic systems that can be made with nanostructures.

- Chapter 6: NANOENGINEERING - How to make nanostructures integrated into useful devices.

- Chapter 7: NANO-BIO PRIMER - An important part of nanotechnology is to interface with living organisms.

- Chapter 8: ENVIRONMENTAL NANOTECHNOLOGY - The environmental issues regarding this emerging technology.

- Chapter 9: NANO AND SOCIETY - Should we worry about nanotechnology?

References

See also notes on editing this book Nanotechnology/About#How_to_contribute.

- ↑ Cristina Buzea, Ivan Pacheco, and Kevin Robbie (2007). "Nanomaterials and Nanoparticles: Sources and Toxicity". Biointerphases. 2: MR17.

{{cite journal}}: CS1 maint: multiple names: authors list (link)

Perspective

| Navigate |

|---|

| << Prev: Introduction |

| >< Main: Nanotechnology |

| >> Next: Overviews |

A perspective on Nanotechnology

Nanotechnology in the Middle Ages?

The Duke TIP eStudies Nanotechnology course will be adding more to this section (this will be completed by 22 Jun 08)

One of the first uses of nanotechnology was in the Middle Ages. It was done by using gold nanoparticles to make red pigments in stained glass showing that nanotechnology has been around for centuries. The gold when clumped together appears gold, but certain sized particles when spread out appear different colors. Reference: The Nanotech Pioneers Where are they taking us? By Steven A Edwards

In the year 1974 at the Tokyo Science University, Professor Norio Taniigrichi came up with the term nanotechnology.

Nanotechnology was first used to describe the extension of traditional silicon machining down into regions smaller than one micron (one millionth of a meter) by Tokyo Science University Professor Norio Taniguchi in 1974. It is now commonly used to describe the engineering and fabrication of objects with features smaller than 100 nanometers (one tenth of a micron). [1]

Nanotechnology has been used for thousands of years, although people did not know what they were doing. For example, stained glass was the product of nanofabrication of gold. Medieval forgers were the first nanotecnologists in a sense, because they, by accident, found out a way to make stained glass.

Reference Nanotechnology A GENTLE INTRODUCTION TO THE NEXT BIG IDEA By Mark Ratner & Daniel Ratner

In 2001, the federal government announced the National Nanotechnology Intiative to coordinate the work of different U.S. agencies and to provide funds for research and accelerate development in nanotechnology. This was spearheaded by Mahail Roco and supported by both president Clinton and Bush.

References The Nanotech Pioneers Where are they taking us? By Steven A. Edwards http://www.nano.gov/html/about/docs/20070521NNI_Industrial_Nano_Impact_NSTI_Carim.pdf

A Vision

Richard Feynman was a man of great importance to the field of nanotechnology. He was a man with a vision. He believed that with research we could change things on a small scale. In his famous speech There's Plenty of Room at the Bottom in 1959, Richard Feynman discussed the possibility of manipulating and controlling things on a molecular scale in order to achieve electronic and mechanical systems with atomic sized components. He concluded that the development of technologies to construct such small systems would be interdisciplinary, combining fields such as physics, chemistry and biology, and would offer a new world of possibilities that could radically change the technology around us.

Miniaturization

A few years later, in 1965, Moore noted that the number of transistors on a chip had roughly doubled every other year since 1959, and predicted that the trend was likely to hold as each new generation of microsystems would help to develop the next generation at lower prices and with smaller components. To date, the semiconductor industry has been able to fulfill Moore's Law, in part through the reduction of lateral feature sizes on silicon chips from around 10 micrometers in 1965 to 45-65 nm in 2007 via changing from the use of optical contact lithography to deep ultraviolet projection lithography.

In 1974 in Japan, Norio Taniguchi coined the word "nano-technology" [2] to describe semiconductor processes such as thin film deposition and ion beam milling exhibiting characteristic control on the order of a nanometer: "‘Nano-technology’ mainly consists of the processing of separation, consolidation, and deformation of materials by one atom or one molecule."

Since Feynman's 1959 speech the arts of "seeing" and "manipulation" at the nanoscale have progressed from transmission electron microscopy (TEM) and scanning electron microscopy (SEM) to various forms of scanning probe microscopy including scanning tunneling microscopy (STM) developed by Binnig and Rohrer at IBM Zurich and atomic force microscopy (AFM) devloped by (Binnig and Quate?) The STM, in particular, is capable of single-atom manipulation on conducting surfaces and has been used to build "quantum corrals" of atoms in which quantum mechanical wave function phenomena can be discerned. These atomic-scale manipulation capabilities prompt thoughts of building up complex atomic structures via manipulation rather than traditional stochastic chemistry. (Note: this pragraph is still rough and references are needed.)

Motivated by Feynman’s beliefs building things nanoscale top-down, Eric Drexler devoted much of his research to making a universal assembler. The American engineer Eric Drexler has speculated extensively about the laboratory synthesis of machines at the molecular level via manipulation techniques, emulating biochemistry and producing components much smaller than any microprocessor via techniques which have been called molecular nanotechnology or MNT. [3] [4] [5]

Successful realization of the MNT dream would comprise a collection of technologies which are not currently practical, and the dream has resulted in considerable hyperbolic description of the resulting capabilities. While realization of these capabilities would be a vindication of the hype associated with MNT, concrete plans for anything other than computer modeling of finished structures are scant. Somehow, a means has to be found for MNT design evolution at the nanoscale which mimics the process of biological evolution at the molecular scale. Biological evolution proceeds by random variation in ensemble averages of organisms combined with culling of the less-successful variants and reproduction of the more-successful variants, and macroscale engineering design also proceeds by a process of design evolution from simplicity to complexity as set forth somewhat satirically by John Gall: "A complex system that works is invariably found to have evolved from a simple system that worked. . . . A complex system designed from scratch never works and can not be patched up to make it work. You have to start over, beginning with a system that works." [6] A breakthrough in MNT is needed which proceeds from the simple atomic ensembles which can be built with, e.g., an STM to complex MNT systems via a process of design evolution. A handicap in this process is the difficulty of seeing and manipulation at the nanoscale compared to the macroscale which makes deterministic selection of successful trials difficult; in contrast biological evolution proceeds via action of what Richard Dawkins has called the "blind watchmaker" [7] comprising random molecular variation and deterministic survival/death.

Technological development and limits

The impact on society and our lives of the continuous downscaling of systems is profound, and continues to open up new frontiers and possibilities. However, no exponential growth can continue forever, and the semiconductor industry will eventually reach the atomic limit for downsizing the transistor. Atoms in solid matter are typically one or two hundred picometers apart so nanotechnology involves manipulating individual structures which are between ten and ten thousand atoms across; for example, the gate length of a 45 nm transistor is about 180 silicon atoms long. Such very small structures are vulnerable to molecular level damage by cosmic rays, thermal activity, and so forth. The way in which they are assembled, designed and used is different from prior microelectronics.

New ways

Today, as that limit still seems to be some 20 years in the future, the growth is beginning to take new directions, indicating that the atomic limit might not be the limiting factor for technological development in the future, because systems are becoming more diverse and because new effects appear when the systems become so small that quantum effects dominate. The semiconductor devices show an increased diversification, dividing for instance processors into very different systems such as those for cheap disposable chips, low power consumption portable devices, or high processing power devices. Microfabrication is also merging with other branches of science to include for instance chemical and optical micro systems. In addition, microbiology and biochemistry are becoming important for applications of all the developing methods. This diversity seems to be increasing on all levels in technology and many of these cross-disciplinary developments are linked to nanotechnology.

Diversification

As the components become so small that quantum effects become important, the diversity will probably further increase as completely new devices and possibilities begin to open up that are not possible with the bulk materials of today's technology.

The nanorevolution?

The visions of Feynman are today shared by many others: when nanotechnology is seen as a general cross disciplinary technology, it has the potential to create a coming "industrial" revolution that will have a major impact on society and everyday life, comparable to or exceeding the impact of electricity and information technology.

Nanocomponents, Tools, and Methods

A positive spiral

As an emerging technology, the methods and components of nanotechnology are under continuous development and each generation is providing a better foundation for the following generation.

Seeing 'nano'

With regards to the methods, the Scanning tunneling microscope (STM) and Atomic Force Microscope (AFM) were developed in the 1980s and opened up completely new ways to investigate nanoscale materials. An important aspect was the novel possibility to directly manipulate nanoscale objects. Transmission and scanning electron microscopes (TEM and SEM) had been available since the 30s, and offered the possibility to image as well as create nanodevices by electron beam lithography.

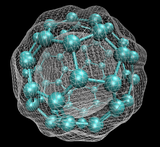

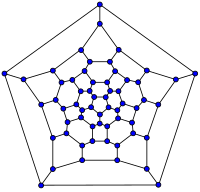

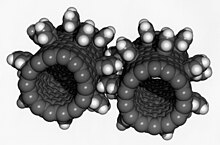

New nanomaterials

Several unique nanoscale structures were also discovered around 1990: the Carbon-60 molecule and later the carbon nanotubes. In recent years, more complex nanostructures such as semiconductor nanowire heterostructures have also proven to be useful building blocks or components in nanodevices.

So what can I use this 'nano' for?

The applications of such nanocomponents span all aspects of technology: Electronics, optics/photonics, medical, and biochemical, as well as better and smarter materials. But to date few real products are available with nanoscale components, apart from traditional nanoscale products, such as paint with nanoparticles or catalytic particles for chemical reactors.

Prototype devices have been created from individual nanocomponents, but actual production is still on the verge. As when integrated electronics were developed, nanotechnology is currently in the phase where component production methods, characterization methods, tools for manipulation and integration are evolving by mutual support and convergence.

Difficult nanointegration

A main problem is reliable integration of the nanoscale components into microsystems, since the production methods are often not compatible. For fabrication of devices with integrated nanocomponents, the optimal manipulation technique is of course to have the individual components self-assembling or growing into the required complex systems. Self assembly of devices in liquids is an expanding field within nanotechnology but usually requires the components to be covered in various surfactants, which usually also influence the component properties. To avoid surface treatments, nanotubes and whiskers/wires can be grown on chips and microsystems directly from pre-patterned catalytic particles. Although promising for future large scale production of devices, few working devices have been made by the method to date.

The prevailing integration technique for nanowire/tube systems seems to be electron beam lithography (EBL) of metal structures onto substrates with randomly positioned nanowires deposited from liquid dispersions. By using flow alignment or electrical fields, the wire deposition from liquids can be controlled to some extent. The EBL method has allowed for systematic investigations of nanowires' and tubes' electrical properties, and creation of high performance electronic components such as field-effect transistors and chemical sensors. These proof-of-principle devices are some of the few but important demonstrations of devices nanotechnology might offer. In addition, nanomechanical structures have also recently been demonstrated, such as a rotational actuator with a carbon nanotube axis built by Fennimore et al.

A more active approach to creating nanowire structures is to use Scanning probe microscopy(SPM) to push, slide and roll the nanostructures across surfaces. SPM manipulation has been used to create and study nanotube junctions and properties. The ability to manipulate individual nanoscale objects has hence proven very useful for building proof-of-principle devices and prototypes, as well as for characterizing and testing components.

Top-down manufacturing takes bulky products and shrinks them to the nano scale, vs. bottom-up manufacturing is when individual molecules are placed in a specific order to make a product.[8] The bottom-up self-assembly method may be important for future large scale production as well as many of the different approaches to improve the top-down lithographic processes. Such techniques could hence become important factors in the self-sustaining development of nanotechnology.

Hot and hyped

Suddenly everything is 'nano'

There's no question that the field of nanotechnology has quite a sense of hype to it - many universities have created new nanotech departments and courses. But there is also a vision behind the hype and emerging results - which are truly very few in industrial production, but nevertheless hold promise for a bright future. In the hype, many things that were once chemistry, microtechnology, optics, mesoscopic or cluster physics, have been reborn as nanotechnology.

Nanotech is old

You can find nanotechnology in the sunscreen you use in the summer, and some paints and coatings can also be called nanotech since they all contain nanoparticles with unique optical properties. In a way, nanoparticles have been known in optics for hundreds of years if you like to take a broad perspective on things, since they have been used to stain and color glasses, etc. since the middle ages. Nano-size particles of gold were used to create red pigments.[9]

Catalysis is a major industrial process, without which not many of the materials we have around us today would be possible to make, and catalysis is often highly dependent on nanoscale catalytic particles. In this way thousands of tons of nanotechnology have been used with great benefit for years.

Nanoscale wires and tubes have only recently really been given attention with the advent of carbon nanotubes and semiconductor nanowires, while nanoscale films are ever present in antireflection coatings on your glasses and binoculars, and thin metal films have been used for sensitive detection with surface plasmons for decades. Surface plasmons are excitations of the charges at a surface. Nanowires actually were observed in the middle ages - well, they did not have the means to observe them, but saw whiskers grow from melted metals.

The better control over the nanostructure of materials has led to optimization of all these phenomena - and the emergence of many new methods and possibilities.

An example

Take for instance nano-optics: The surface plasmons turn out to be very efficient at enhancing local electrical fields and work as a local amplifier for optical fields, making a laser seem much more powerful to atoms in the vicinity of the surface plasmon. From this comes the surface enhanced raman spectroscopy which is increasingly used today because it makes it possible to do sensitive raman spectroscopy on the large majority of samples that would otherwise be impossible to make such spectra on. In addition, photonic crystals, fancy new quantum light sources that can make single photons on demand and other non-classical photon states are being developed, based on nanotechnology.

The future

There are definitely future scientific applications and commercial potential of all these new methods to handle light, use it for extremely sensitive detection and control its interaction with matter - and so it seems nanotechnology, being about making smaller versions of existing technology as well as new technology, is worth a bit of hype.

References

See also notes on editing this book Nanotechnology/About#How_to_contribute. .

- ↑ Edwards, Steven (2006). The Nanotech Pioneers: Where are they taking us?. Wiley-VCH. ISBN 3527312900.

- ↑ N. Taniguchi, "On the Basic Concept of 'Nano-Technology'," Proc. Intl. Conf. Prod. Eng. Tokyo, Part II, Japan Society of Precision Engineering, 1974.

- ↑ Steven A. Edwards, The Nanotech Pioneers, (WILEY-VCH, 2006)

- ↑ Eric Drexler, Engines of Creation, (New York: Anchor Press/Doubleday, 1986).

- ↑ Eric Drexler, Nanosystems: Molecular Machinery, Manufacturing and Computation, (New York: John Wiley, 1992).

- ↑ Gall, John, (1986) Systemantics: How Systems Really Work and How They Fail, 2nd ed. Ann Arbor, MI : The General Systemantics Press.

- ↑ Richard Dawkins, The Blind Watchmaker: Why the Evidence of Evolution Reveals a Universe Without Design, W. W. Norton; Reissue edition (September 19, 1996)

- ↑ Eric Drexler, Engines of Creation

- ↑ Nanotech Pioneers, Steven A. Edwards (WILEY-VCH, 2006, Weinheim)

Overviews

| Navigate |

|---|

| << Prev: Perspective |

| >< Main: Nanotechnology |

| >> Next: About |

Internet Resources

Handbooks and Encyclopedias

These are only accessible for subscribers (which is one reason this Wikibook on Nanotechnology was started):

- Encyclopedia of Nanoscience and Nanotechnology, 10-Volume Set

- Handbook of Theoretical and Computational Nanotechnology, 10-Volume Set

- Springer Handbook of Nanotechnology

Websites and newsletters

- International Council on Nanotechnology (ICON) a multi-stakeholder group dedicated to the safe, responsible and beneficial development of nanotechnology. ICON serves as an aggregator for news and research related to nanotechnology environment, health and safety.

- ICON Virtual Journal of Nanotechnology Environment, Health and Safety compiles papers in peer-reviewed journals that address EHS issues in nanotechnology.

- Virtual journal of nanotechnology compiles nano-related papers in peer reviewed journals that do not specialize solely in nanotechnology.

- ACS Nanotation

- Nanotechweb.org

- Nanoforum

- Nanowerk

- nanoRISK

- Physorg.com

- Foresight Nanotech Institute

- Center for Responsible Nanotechnology

- A-Z of nanotechnology

- Google Directory - Nanotechnology (sourced from the Open Directory Project)

- Scientific American Nanotechnology Page

- NanoEd Resource Portal managed by the National Center for Learning and Teaching in Nanoscale Science and Engineering (NCLT)

- NanoHub.org

- UnderstandingNano

Search engines

There are many ways to find information in scientific literature and some that even specialize in nanotechnology. Apart from the free search engines and useful tools such as Google scholar and Google Desktop, there are several more dedicated commercial services:

- ICON Virtual Journal of Nanotechnology Environment, Health and Safety (VJ-NanoEHS) compiles papers in peer-reviewed journals that address EHS issues in nanotechnology.

- ISI - Web of Science Database contains peer reviewed journals, their references and citations. It also has very useful tools such as 'find related papers' that searches for papers sharing the same references as the entry you're looking at. This is the database behind the compilation of the journal citation factors.

- Knovel - Online Handbook Collection and Database is an extensive collection of handbooks and tables.

- PROLA - the Physical Review Online Archive searches Physical Review journals.

- Rubber Bible Online is a physical chemistry handbook which contains tables of physical and chemical data.

- Spin AIP Scitation searches related journals.

- Web of Science by ISI generates the impact factors (see journals below).

- Virtual Journal of Nanotechnology collects nanotech related papers from non-nano specialized journals.

- Derwent Patent database

Peer reviewed Journals

Overview of the nanotechnology related journals and their impact factors (2007 values):

| Name | Web | Impact Factor | ISSN | Comments | |

|---|---|---|---|---|---|

| ACS Nano | [9] | N/A | 1936-0851 | general nanotech journal | |

| Advanced Functional Materials | [10] | 7.5 | 1616-301X | ? | |

| Advanced Materials | [11] | 8.2 | 0935-9648 | ? | |

| American Journal of Physics (AJP) | [12] | 0.9 | 0002-9505 | ? | |

| Applied Physics A: Materials Science & Processing | [13] | 1.9 | 0947-8396 | ? | |

| Applied Physics Letters (APL) | [14] | 3.6 | ? | ? | |

| AZojono - Journal of Nanotechnology Online | [15] | N/A | ? | Free access journal | |

| Chemical Reviews | [16] | 22.8 | 0009-2665 | ? | |

| Current Nanoscience | [17] | 2.8 | 1573-4137 | Reviews and original research reports | |

| Fullerenes, Nanotubes, and Carbon Nanostructures | [18] | 0.5 | 1536-383x | all areas of fullerene research | |

| IEEE Transactions on Nanotechnology | [19] | 2.1 | 1536-125X | physical basis and engineering applications of nanotechnology | |

| International Journal of Nanomedicine | [20] | N/A | 1176-9114 | ? | |

| International Journal of Nanoscience | [21] | N/A | 0219-581X | New nanotech journal (Feb 2002) | |

| Japanese Journal of Applied Physics | [22] | 1.2 | 1347-4065 | ? | |

| Journal of Applied Physics | [23] | 2.2 | ? | ? | |

| Journal of Biomedical Nanotechnology | [] | N/A | ? | JBN is a peer-reviewed multidisciplinary journal providing broad coverage in all research areas focused on the applications of nanotechnology in medicine, drug delivery systems, infectious disease, biomedical sciences, biotechnology, and all other related fields of life sciences. | |

| Journal of Experimental Nanoscience | [24] | N/A | 1745-8080 | New nanotech journal(March 2006) | |

| Journal Of Microlithography Microfabrication And Microsystems | [25] | N/A | 1537-1646 | ||

| Journal of Micromechanics and Microengineering | [26] | 1.9 | 0960-1317 | ? | |

| Journal of Nano Research | [27] | N/A | 1661-9897 | ||

| Journal of Nanomaterials | [28] | N/A | ? | science and applications of nanoscale and nanostructured materials | |

| Journal of Nanoparticle Research | [29] | 2.3 | 1388-0764 | ? | |

| Journal of Nanoscience and Nanotechnology | [30] | 2.0 | ? | JNN is a multidisciplinary peer-reviewed journal covering fundamental and applied research in all disciplines of science, engineering and medicine. JNN publishes all aspects of nanoscale science and technology dealing with materials synthesis, processing, nanofabrication, nanoprobes, spectroscopy, properties, biological systems, nanostructures, theory and computation, nanoelectronics, nano-optics, nano-mechanics, nanodevices, nanobiotechnology, nanomedicine, nanotoxicology. | |

| Journal of Physical Chemistry A | [31] | 2.9 | ? | ? | |

| Journal of Physical Chemistry B | [32] | 4.1 | ? | ? | |

| Journal of Physical Chemistry C | [33] | N/A | ? | Nanomaterials and Interfaces, Nanoparticles and Nanostructures, Surfaces, Interfaces, Catalysis, Electron Transport, Optical and Electronic Devices, Energy Conversion and Storage | |

| Journal of the American Chemical Society (JACS) | [34] | 7.9 | ? | Multidisciplinary chemistry journal | |

| Journal of Vacuum Science & Technology A (JVSTA) | [35] | 1.3 | ? | Vacuum, Surfaces, Films | |

| Journal of Vacuum Science & Technology B (JVSTB) | [36] | 1.4 | ? | Microelectronics and Nanometer Structures: Processing, Measurement, and Phenomena | |

| Langmuir | [37] | 4.0 | ? | Research in the fields of colloids, surfaces, and interfaces | |

| Micron | [38] | 1.7 | ? | Journal for Microscopy | |

| Materials Chemistry and Physics | [39] | 1.9 | 0254-0584 | materials science, including nanomaterials and opto electronics | |

| Materials Science and Engineering: C | [40] | 1.3 | 0928-4931 | Biomimetic and Supramolecular Systems | |

| Materials Science and Engineering: R: Reports | [41] | 17.7 | 0927-796X | Invited review papers covering the full spectrum of materials science and engineering | |

| Materials Today | [42] | N/A | 1369-7021 | materials science and technology | |

| Microfluidics and Nanofluidics | [43] | 2.2 | 1613-4982 | all aspects of microfluidics, nanofluidics, and lab-on-a-chip science and technology | |

| Microscopy Research and Technique | [44] | 1.6 | ? | ? | |

| Nano | [45] | N/A | 1793-2920 | New nanotech journal (July 2006) | |

| Nano Letters | [46] | 9.6 | ? | General nanotechnology journal | |

| Nanomedicine | [47] | 2.8 | ? | ? | |

| Nanopages | [48] | N/A | 1787-4033 | Since sept 2006. | |

| Nano Research | [49] | N/A | ? | First issue july 2008 | |

| Nano Research Letters | [50] | wait | 1931-7573 | articles with open access | |

| Nanotechnology | [51] | 3.3 | ? | Journal specializing in nanotechnology | |

| NanoToday | [52] | N/A | ? | Is this peer reviewed or more a news/reviews journal? | |

| Nature | [53] | 31.434 | ? | One of the major journals in science | |

| Nature Biotechnology | [54] | 22.8 | ? | advances in life sciences | |

| Nature Materials | [55] | 19.8 | ? | covers a range of topics within materials science | |

| Nature Methods | [56] | 15.5 | ? | tried-and-tested techniques in the life sciences and related area of chemistry | |

| Nature Nanotechnology | [57] | 14.9 | ? | mix of news, reviews, and research papers | |

| Nanotoxicology | [58] | N/A | 1743-5404 | Research relating to the potential for human and environmental exposure, hazard and risk associated with the use and development of nano-structured materials | |

| Open Nanoscience Journal | [59] | N/A | 1874-1401 | Open access journal with research articles, reviews and letters. | |

| Physical Review Letters (PRL) | [60] | 6.9 | ? | One of the top physics journals | |

| PLoS Biology | [61] | 13.5 | 1544-9173 | Peer reviewed open access bio journal | |

| PLoS ONE | [62] | N/A | ? | Peer reviewed open access science journal | |

| Proceedings of the National Academy of Sciences(PNAS) | [63] | 10.2 | ? | multidisciplinary scientific serial: biological, physical, and social sciences. | |

| Recent Patents on Nanotechnology | [64] | N/A | 1872-2105 | ? | |

| Science | [65] | 26.4 | ? | One of the major journals in science | |

| Solid-State Electronics | [66] | 1.3 | ? | ? | |

| Small Journal | [67] | 6.4 | 1613-6810 | New nanotech journal | |

| Smart Materials and Structures | [68] | 1.5 | 0964-1726 | since 1992 | |

| Thin Solid Films | [69] | 1.7 | 0040-6090 | Thin-film synthesis, characterization, and applications. | |

| Ultramicroscopy | [70] | 2.0 | ? | Microscopy related research. | |

| Virtual Journal of Nanotechnlogy | [71] | N/A | 1553-9644 | Collecting nanotech related papers from non-nano spcialized journals |

- Impact factors are only guides to how much a papers is referenced in the years just after publication.

- Please add comments about the journals and update impact factors!

- The Physics and Astronomy Classification Scheme PACS2006 and Nanoscale Science and Technology - Collection of Applicable Terms from PACS 2006

Conferences

- NSTI Nanotech 2008

- TNT - Trends in Nanotechnology 2007;2006

- MNE - Micro and Nanoengineering 2007;2008

- Virtual Conference on Nanoscale Science and Technology

- Foresight Unconference Vision Weekend NanoBioInfoCognoSocioPhysical technologies

- [72]

- International Microprocess and Nanotechnology Conference, Japan

- Nanosafe 2008: International Conference on Safe production and use of nanomaterials

Nanotech Products

Please add more products, comments and more info about the products if you have any!

See also the List of nanotechnology applications in wikipedia

Woodrow Wilsom Center for International Scholars is starting a Project on Emerging Nanotechnologies (website should be under construction at www.nanoproject.org) that among other things will try to map the available 'nano'products and work to ensure possible risks are minimized and benefits are realized.

Emerging products

- 2008 MultiProbe’s AFM Nanoprober is now qualified for 32nm technology nodes. [73]

- Intel will make products with 45 nm linewidth transistors available from 2008 [74]

- Batteries are increasingly incorporating nanostructures.

- Flexible, cheaper, or more luminous Flat screen displays

- Pressure-sensitive mobile devices [75]

Available in 2006

- Surface coatings: TCnano, Nanocover, Stay clean.

Available in 2005

- Molybdenum disulfide catalytic nanoparticles in Brimm catalysts[76] made by Haldor Topsøe

- Forbes top ten nanoproducts in 2005[77]

- Apples IPod with sub 100nm elements in its memory chips

- Choleterol reducing nanoencapsulated oil,Shemen Industries Canola Active.

- Nanocrystals improve the consistency of chocolate[78]

- Zelen Fullerene C-60 Day Cream [79]

- Easton Stealth CNT baseball bat

- Nanotex textiles once again

- ArcticShield polyester socks from ARC Outdoors with 19nm silver particles that kill fungs to reduce odor.

- NanoGuard developed by Behr Process for improved paint hardness.

- Pilkingtons self-cleaning 'Activ Glass'.

- NanoBreeze Air Purifier from NanoTwin Technologies, where the UV light from a fluorescent tube cleans the air by photochemical reactions in nanoparticles.

Available in 2004

- Cold cathode carbon nanotube emitters for X-ray analysis by Oxford instruments[80][]

- Forbes has an overview in 2004 of what they consider the top ten nanotech products:

- Footwarmers with nanporous aerogel for 3-20 times lighter than comparable insulating materials used in shoes (produced by Aspen Aerogels).

- Matress covers with nanotex fibres that can be washed (Simmonos bedding company).

- Better golf drivers with carbon nanotube enforced metal composites (produced by Maruman & Co) and nanocomposite containing golf balls (produced by NanoDynamics)

- The company 'Bionova' apparently adds some nanoproducts to their 'personalized product line'.

- EnviroSystems make a nanoemulsive disinfectant cleaner, called EcoTru, that is EPA Tox category 4 registered (meaning very safe to use)

- EnviroSystems also make a spray-on version of this product.

- BASF makes a nanoparticle coating for building materials called Mincor, that reduces their wettabililty.

- A nanostructured coating produced by Valley View, called Clarity Defender, improves visibility through windscreens in rain. Another company, Nano-Film, makes a similar coating on sunglasses.

- w:Flex-Power makes a gel containing nanoscale liposomes for soothing aching muscles

- 3M espe Dental adhesive with silica nanoparticle filler.

Available in 2003

- NanoGuard Zink Oxide nanoparticles for sunscreens FDA approved

- Forbes 2003 top ten nanoproduct [81] includes:

- High performance ski wax, Cerax Nanowax [82].

- Nanotex textiles in ski jackets from Ziener[83]

- Nanotex textiles

- Plenitude Revitalift antiwrinkle cream by L'Oréal contains nanocapsules with vitamin A [84]

- organic light-emitting diodes (OLEDs) in Sony camera flat screen display

- Nanofilm coatings for ani-reflection and scratch resistance [85]

- Zink oxide nanoparticles in Sunscreen by BASF [86]

- carbon nanotube enforced tennis rackets [87] and nanopolymer enforced tennis balls [88]

Available in 2000

Nanotex makes textiles where the clothing fibres have been coating in nanoscale fibres to change the textile wettability. This makes the textile much more stain resistant.

Companies making nanotech research equipment

- MultiProbe Manufacturer of a 1-to-6 head Atomic Force nanoprobing tool used in failure analysis, that combines multi-scan fault isolation imaging with nanoprobing electrical capabilities. For process technology node measurements of 32nm, 45nm, 65nm, 90nm or larger.

- Veeco AFM and related equipment

- Zyvex nanomanipulation equipment

- Nanofactory in-situ TEM manipulation equipment

- SmarAct nanomanipulators

- Capres micro four point conductance measurement probes

- ImageMetrology SPIP software for SPM analysis

- QuantumWise software for simulating nanosystems

- [89] AFM and related equipment

Products that have been nanostructured for decades

- Catalysts

- Computer processesors are increasingly made of nanoscale systems

Non-nanotech products and a warning

Not everything that says nano is nano - and given the hype surrounding nanotechnology you will see an increasing number of 'nano' products that have nothing to do with it. It is worrying when sometimes problems arise with non-nano products and this adds to the 'scare' that is present in the public, fuelled by the newspapers where they are just waiting for a nice scandal... an example was the product Magic Nano from a German company that made a number of users sick when inhaling the aerosol cleaning product - which in the end turned out to have nothing 'nano' in it. There is good reason to be very alert to such issues. Not all countries have legislation in place to secure the consumers against the possible dangers present in nanoparticles and some products could end being marketed before having been tested well enough. Though this example turned out to be 'non-nano', we will probably meet new cases shortly that are truly 'nano'. On this background environmental and health aspects will be an important part of this book.

Suppliers

Nanomaterials

Nanolithography

- NIL Technology sells stamps for nanoimprint lithography (NIL) and provides imprint services.

Quantum Dots

A nano-timeline

Overview of some important events in nanotechnology

See also History of Nanotechnology in Wikipedia

| Year | Development | |||

|---|---|---|---|---|

| Medieval | Observation of metal whisker growth and nanoparticles used for staining glass | |||

| 1900 | Max Planck proposes energy quantization. | |||

| 1905-30 | Development of quantum mechanics | |||

| 1927 | Heisenberg formulated his uncertainty principle | |||

| 1933 | The first First electron microscope was built by Ernst Ruska | |||

| 1952 | First carbon nanotubes observation by Radushkevich and Lukyanovich | |||

| 1953 | DNA structure discovered by James D. Watson and Francis Crick | |||

| 1959 | Feynmanns talk There is plenty of room at the bottom | |||

| 1965 | Proposal of Moores Law | |||

| 1981 | Invention of STM by Gerd Binnig and Heinrich Rohrer | |||

| 1985 | Invention of AFM by Binnig, Quate and Gerber | |||

| 1985 | Buckyball discovery by Harry Kroto, Robert Curl, and Richard Smalley | |||

| 1986 | K. Eric Drexler publishes his book Engines of Creation, in which he discusses both the potential huge benefits and the potential dangers of nanotechnology. He talks about a future of nanotechnology defined by molecular manufacturing, where self-replicating nanobots/assemblers are engineered to carry out practical applications. | |||

| 1989 | Don Eigler pushed around xenon atoms to spell IBM | – | 1991 | Rediscovery of carbon nanotubes by Sumio Iijima |

A nano-scale overview

Just to get a sense of proportion

| Scale | typical elements |

|---|---|

| 1 m | 1 m is 1.000.000.000 nanometers ( 10^9 nm ) |

| 200 µm | About the size of the smallest letters you can write with a very very sharp pencil and a very very steady hand. |

| 100 µm | Typical thick hair |

| 10-1000 µm | Cells in living organisms can have many sizes, and neurons can be much longer. In frog embryos (Tadpoles) the initial embryo cells can be up to 1000µm. |

| 8 µm | Red blood cell |

| 1 µm | Bacteria |

| 100 nm | Virus |

| 5-100 nm | The range for nanotechnology systems built from atomic/molecular components (quantum dots, nanoparticles, diameter of nanotubes and nanowires, lipid membranes, nanopores...). |

| 10 nm | Size of typical Antibody molecules in living organisms immune defence |

| 6-10 nm | Thickness of a cell membrane, and typical pore size in membrane. |

| 2.5 nm | The width of DNA (but it depends on the conditions) |

| 1 nm | The size of a C60 buckyball molecule or glucose molecule. |

| 0.3 nm | The size of a water molecule. |

| 1 Å = 0.1 nm | Roughly the size of hydrogen atom. |

| 0.7 Å = 70 pm | The best resolution in AFM achieved so far where they managed to image individual orbitals in an atom. |

- Distances between objects can be measured with sub Å precision with STM, laser interferometry and its even done continuously in a standard airbag acceleration sensor chip that costs a few dollars and senses the vibrations of a micro-inertial mass element with femtometer precision (10^-15 m).

Bibliography

- G. Ali Mansoori, Principles of Nanotechnology, Molecular-Based Study of Condensed Matter in Small Systems, (New Jersey: World Scientific, 2006).

- Monthioux, Marc; Kuznetsov, Vladimir L. (2006). "Who should be given the credit for the discovery of carbon nanotubes?". Carbon 44. doi:10.1016/j.carbon.2006.03.019. Retrieved on 2007-07-26.

References

See also notes on editing this book Nanotechnology/About#How_to_contribute.

the nanotechnology pioneers by Steven A. Edwards Engines of Creation 2.0: The Coming Era of Nanotechnology by K. Eric Drexler

About the Book

| Navigate |

|---|

| << Prev: Overviews |

| >< Main: Nanotechnology |

| >> Next: Reaching Out |

Vision

We hope to use the Wikibooks format to make an Open Source Handbook on Nanoscience and Nanotechnology, freely accessible for everyone, that can be updated continuously.

Wikipedia is growing fast and one of the most visited websites on the net – a valuable resource of information we all use.

In science and technology we often need more detailed information than what can be presented in a brief encyclopedic article – and here wikibooks.org, a sister project to Wikipedia, can help us with this newly started handbook.

Though the book is still in its infancy, it has been elected book of the month December 2006, and we hope this will provide PR and more people contributing to the project!

The plan to create the book:

1: First to create smaller articles to ‘cover’ the entire area of nanotechnology and achieve a well defined structure the book (some parts could be revised thoroughly in this process,for instance the materials chapter).

2: Once the structure is reasonably well defined, to begin refining the articles with in-depth material so we reach lecture-note level material.

3: Since everybody can contribute, a continuous contribution of material is expected and a backing group of editors is needed to maintain a trustworthy level of information.

An voluntary editorial board is being put together to oversee the book, support, contribute and follow its development.

Discussion about the content of the book can be found on the main talk page talk:Nanotechnology

As with Wikipedia, we hope to see a solid information resource continuously updated with open source material available for everyone!

Editing hints

References in Wikibooks

Add references whenever possible, with reference lists at the end of each page. Please try to make links to the articles with the DOI (digital object identifier) because that gives a uniform and structured access for everyone to the papers.

All papers get a DOI - a unique number like a bar code in a supermarket. All DOIs are registered by www.doi.org and in the reference list you can add links like https://doi.org/10.1039/b504435a so people will be able to find it no matter how the homepage of the journal or their own library changes.

The References section has an example reference.

Add links to the Wikipedia whenever possible - and for the beginning I will rely extensively on Wikipedia's pages on the subjects, simply referring to these. This textbook could be simply a gathering of Wikipedia pages, but an encyclopedia entry is brief, and for a handbook it is preferable to have more in-depth material with examples and the necessary formulas. So, some information in this textbook will be very much like the Wikipedia entries and we might not need to write it in the book but can simply refer to Wikipedia, but the hope is that this will be more a text book as is the intention with Wikibooks.

Multiple references, see w:Help:Footnotes

Links

There's a shorthand way to make links to Wikipedia from Wikibooks: [[w:Quantum_tunneling|Wikipedia on Quantum Tunneling]] gives the link Wikipedia on Quantum Tunneling.

Media

History

The book was started by Kristian Molhave (wiki user page) 13. Apr. 2006. Initially it was named Nanowiki, and later changed to Nanotechnology. Kristian is currently slowly uploading material to the book and looking for people who would like to contribute that can and substantial material to specific sections under the GNU license. I hope we can make an 'editorial panel' of people each keeping an eye on and updating specific sections.

The Summer 2008 Duke Talent Identification Program (TIP) eStudies Nanotechnology students will be adding to the content of this Wikibook. From June-Aug 2008 there will be content additions with references that will add to this great resource.

Authors and Editors

- The Opensource Handbook on Nanoscience and Nanotechnology was started by Kristian Molhave(wiki user page)

Editors

- An editorial board is currently being organized.

Support and Acknowledgments

Starting this book is supported by the Danish Agency for Science, Technology and Innovation through Kristian Mølhave's talent project ’NAMIC’ No. 26-04-0258.

How to Reference this Book

I am not currently sure how work on wikibooks or wikipedia can be referenced reliably in published literature.

Three suggestions:

1) Reference the references from the wikibook. Wikibooks are not intended to be the publication channel for new results, but should be based on published and accepted information with references and these references can be used. But this of course does not give credit to the book, so I recommend then adding an acknowledgement about the book to give it PR and credit.

2) Reference the book with a specific page and date - the previous versions of the pages are all available in the history pane and can easily be accessed by future users. You can also hit "permanent version" on the left side of the webpage (it is under "toolbox"). That sends you specifically to the selected version of the wikipage with a link to it that will never change.

3) Reference the PDF version and its version number. Once the book achieves a reasonable level, PDF versions will become available for download and they will have a unique version number and can be retrieved.

Other suggestions are most welcome!

Edwards, Steven A.,The Nanotech Pioneers

Christiana, USA:

Wiley-VCH 2006, pg 2

Reaching Out

| Navigate |

|---|

| << Prev: About |

| >< Main: Nanotechnology |

| >> Next: Seeing Nano |

Teaching Nanotechnology

Teachers' Toolbox is a Wikibook on teaching methods and ways to improve teaching. The toolbox is intended to give you an overview of methods you can use when teaching in general.

If you know of places that have teaching material available on the net, please add a link to the list below:

Outreach projects

There are several nanotechnology related outreach projects. Here are some examples to give ideas:

- Nanoscale Science Education

- Citizens school of nanotechnology

- Webcast outreach lecture

- Exploring the nanoworld

- K-14 outreach

- Cornell Museum

Demonstration experiments

There is a dedicated section for nanotechnology in the Wikiboook on Science Show, which is a cross disciplinary collection of demonstration experiments. The is growing steadily and we will begin to add to the English version soon. Please add to these books with any demonstration experiments and ideas you have!

There are others available on the net:

- Nano-Tex: Testing New Nano Fabrics

- Nano kits and for instance the exercise moving a wall

References

See also notes on editing this book about how to add references Nanotechnology/About#How_to_contribute.

Part 2: Seeing 'Nano'

| Navigate |

|---|

| << Prev: Reaching Out |

| >< Main: Nanotechnology |

| >> Next: Optical Methods |

|

|

| <<< Prev Part: Introduction |

| >>> Next Part: Physics - on the nanoscale |

The eyes in nanotech

Without being able to 'see' the nanoscale objects, nanotechnology would be very difficult. In this part, the different microscope techniques are reviewed along with various spectroscopic and diffraction methods that can tell us more about the nanoscale structure of matter.

Visible light is only a part of the electromagnetic spectrum and useful information about different physical interactions in nanostructures can be acquired from the different parts of the electromagnetic spectrum.

Seeing 'nano' can be done in different ways, but not with the naked eye which normally cannot see things much smaller than 100µm (though a single atom can be seen if it lights up in a dark room). Instead of our eyes, we use various instruments to 'see' for us, and they 'see' different things depending on how they are made:

Microscopy

Microscopy uses microscopes to create an image of the specimen. The image is rarely an image as you see it with your eyes, but rather how some physical probe interacts differently with the specimen as function of position on it. The physical probe can be an AFM cantilever, a beam of light or electrons, or something completely different.

Overview of Microscopes

Optical: The beam from a light source is focused onto a sample and either the transmitted or scattered light is collected by an objective lens and the image is magnified onto a camera or to the observer's eye. The resolution can be down to about 200 nm, and the microscopes can be fairly cheap, small and easy to use.

Transmission Electron Microscope (TEM): Electrons from a very bright electron source are directed to a very thin sample that is transparent to the high energy electrons (100-300 keV) and the electron beam is then magnified by electromagnetic lenses and sent onto a fluorescent screen or a camera to observe the image. The resolution can be less than 0.1 nm on expensive high-end instruments where even individual atoms can be imaged. The samples must be very thin (typically less than 200 nm) and the whole system must be under high vacuum.

Scanning Electron Microscope (SEM): A focused electron beam is scanned over a sample and the scattered electrons are detected. The detector current is used to give an image depending on the electron beam position on the sample. The resolution can be down to about 5 nm and the sample can be much larger than in the TEM because the electrons do not have to pass through the sample.

Scanning Probe Microscopes (SPM) move a very sharp probe across a sample in a raster pattern while recording how the probe interacts with the sample. The typical SPMs are the AFM, STM and SNOM:

Atomic Force Microscope (AFM): An almost atomically sharp tip is protruding from a cantilever and is scanned over the sample. When the cantilever deflects, a laser beam reflected off the backside of the cantilever will change directions and this will be measured by a photodetector. The laser position can be used to control the force between the tip and the sample, and the AFM is often used to measure both topography and forces on the nanoscale. The resolution is normally down to about 1 nm, but even subatomic resolution is possible. The AFM can work with both dry and wet, conducting and isolating samples.

Scanning Tunneling Microscope (STM): An atomically sharp tip is moved within atomic distance of a sample that has a voltage applied to it. When the tip-sample distance becomes so small that the electron clouds of the tip and sample touch, electrons can much more easily tunnel between the two and this gives rise to a tip-sample current (often a few pA at a 1V bias voltage). This current can be used to maintain a fixed tip-sample distance when the tip is scanned over the sample, and this can give images of conducting surfaces with atomic resolution.

Scanning Near-field Optical Microscope (SNOM): As electrons can tunnel between electrical conductors in the STM, photons can tunnel between optical guiding structures. The SNOM uses a narrow light guide to measure how the optical electromagnetic field changes as the guide is moved across the sample. For instance, light can be sent from below the sample and then scattered into the scanning light guide above it. The resolution can be much smaller than the wavelength of light.

Point-Projection Microscopes: The Field Emission Microscope (FEM), Field Ion Microscope (FIM) and the atom probe are examples of point-projection microscopes where ions are excited from a needle-shaped specimen and hit a detector. The Atom-Probe Tomograph (APT) is the most modern incarnation and allows a three-dimensional atom-by-atom (with chemical elements identified) reconstruction with sub-nanometer resolution.

Spectroscopy

Spectroscopy uses spectrometers to tell how radiation interacts with the specimen as function of the energy/wavelength of the radiation

Diffraction

Diffraction uses radiation to observe how it is scattered in different directions from the specimen. This can be used to tell about the order of the atoms in the sample.

Surface analysis

Many of these methods are used for 'macroscopic' surface analysis where the outmost nanometers of a material is being studied over larger areas. The methods can be combined with microscopes to give spectrometrical information from a well defined location on the sample - for instance when doing diffraction measurements in a TEM or level spectroscopy in an STM on a single atom.

References

See also notes on editing this book about how to add references Nanotechnology/About#How_to_contribute.

Optical Methods

| Navigate |

|---|

| << Prev: Seeing Nano |

| >< Main: Nanotechnology |

| >> Next: Electron Microscopy |

Optical Microscopy

The Abbe diffraction limit

Observation of sub-wavelength structures with microscopes is difficult because of the Abbe diffraction limit. Ernst Abbe found in 1873 that light with wavelength λ,travelling in a medium with refractive index n and converging to a spot with angle φ will make a spot with radius

The denominator nsinφ is called the numerical aperture (NA) and can reach about 1.4 in modern optics, hence the Abbe limit is roughly d=λ/2. With green light around 500nm the Abbe limit is 250nm which is large compared to most nanostructures or biological cells with sizes on the order of 1μm and their internal organelles being much smaller. To increase the resolution, shorter wavelengths can be used such as UV and X-ray microscopes. These techniques offer splendid resolution but are expensive, suffer from lack of contrast in biological samples, and also tend to damage the sample.

Resources

- Microscope optics

- Microscopy Primer

- Olympus Interactive Java Tutorials on Microscopy

- Nikon MicroscopyU with interactive tutorials on microscopy techniques

The optical microscope

Bright Field

The light is sent to the sample in the same directions as you are looking - most things will look bright unless they absorb the light.

Dark Field

Light is sent towards the sample at an angle to your viewing direction and you only see light that is scattered. This makes most images appear dark and only edges and curved surfaces will light up.

Polarized Light

DIC vs H

Laser Scanning Confocal Microscopy (LSCM)

Confocal laser scanning microscopy is a technique that allows a much better resolution from optical microscopes and three dimensional imaging. A review can be found in Paddock, Biotechniques 1999

Using a high NA objective also gives a very shallow depth of focus and hence the image will be blurred by structures above or below the focus point in a classical microscope. A way to circumvent this problem is the confocal microscope, or even better the Laser Scanning Confocal Microscope (LSCM). Using a laser as the light source gives better control of the illumintaion, especially when using fluorescent markers in the sample. The theoretical resolution using a 1.4 NA objective can reach 140nm laterally and 230nm vertically [1] while the resolution quoted in ref [2] is 0.5×0.5×1μm. The image in the LSCM is made by scanning the sample in 2D or 3D and recordning the signal for each point in space on a PC which then generates the image.

X-ray microscopy

X-ray microscopy uses X-rays to image with much shorter wavelength than optical light, and hence can provide much higher spatial resolution and use different contrast mechanisms. X-ray microscopy allows the characterization of materials with submicron resolution approaching the 10's of nanometers. X-ray microscopes can use both laboratory x-ray sources and synchrotron radiation from electron accelerators. X-ray microscopes using synchrotron radiation provide the greatest sensitivity and power, but are unfortunately rather large and expensive. X-ray microscopy is usually divided into two overlapping ranges, referred to as soft x-ray microscopy (100eV - 2keV) and hard x-ray microscopy (1keV-40keV). All x-rays penetrate materials, more for higher energy x-rays. Hence, soft x-ray microscopy provides the best contrast for small samples. Hard x-rays do have the ability to pass nearly unhindered through objects like your body, and hence also give rather poor contrast in many of the biological samples you would like to observe with the x-ray microscope. Nevertheless, hard x-ray microscopy allows imaging by phase contrast, or using scanning probe x-ray microscopy, by using detection of fluorescent or scattered x-rays. Despite its limitations, X-ray microscopy is a powerful technique and in some cases can provide characterization of materials or samples that cannot be done by any other means.

UV/VIS spectrometry

Infrared spectrometry (FTIR)

vIdentification of the functional groups present in a nanomaterial is a frequent requirement in nanoscience and nanotechnology research. Among other tools, FT-IR has found much popularity among researches due to its versatility, relative ease of use and ability to use as a quantification tool.

Atoms in a chemical bonds constantly vibrate. This vibration can be analogue to a system with two masses attached to a spring. The vibration frequency depend upon the weight of the masses and the spring constant of the connecting spring. In the same way, depending on the masses of the atoms that contributes to a bond and cohesiveness of the bond, frequency differ. Since bonds have atoms with different shapes and sizes and different strength, each combination of atoms in an each type of bond has a unique harmonic frequency. This natural frequency lies in the range of infrared region and therefore a spectroscopic method that use IR can be devised to analyze bond vibrations.

When the IR radiation with the same harmonic frequency of the bond shines upon the bond. The bond vibration is amplified by increased transfer of energy from the IR radiation. When range of IR frequencies given to the material, it only absorb IR frequencies that corresponds to the natural frequencies of the bonds that exist in the sample. Others are not absorbed and can be analyzed using an Infrared spectrometer, which tells you the frequencies that are absorbed by the sample. This provides important information about the functional groups present in the sample. This is exactly what FT-IR does.

As FT-IR can be used to get information about functional groups present in nanomaterials. This is particularly useful in cases such as when one attempts to surface modify nanomaterials to increase affinity, reactivity or compatibility. Analyzing the FT-IR of a nanomaterial would tell you what groups present and then appropriate surface modification strategy be decided based on the groups present. Further, it can also be useful in characterizing the surface modification has taken place, as new groups should emerge if the reaction is successful.Identification of the functional groups present in a nanomaterial is a frequent requirement in nanoscience and nanotechnology research. Among other tools, FT-IR has found much popularity among researches due to its versatility, relative ease of use and ability to use as a quantification tool.

Atoms in a chemical bonds constantly vibrate. This vibration can be analogue to a system with two masses attached to a spring. The vibration frequency depend upon the weight of the masses and the spring constant of the connecting spring. In the same way, depending on the masses of the atoms that contributes to a bond and cohesiveness of the bond, frequency differ. Since bonds have atoms with different shapes and sizes and different strength, each combination of atoms in an each type of bond has a unique harmonic frequency. This natural frequency lies in the range of infrared region and therefore a spectroscopic method that use IR can be devised to analyze bond vibrations.

When the IR radiation with the same harmonic frequency of the bond shines upon the bond. The bond vibration is amplified by increased transfer of energy from the IR radiation. When range of IR frequencies given to the material, it only absorb IR frequencies that corresponds to the natural frequencies of the bonds that exist in the sample. Others are not absorbed and can be analyzed using an Infrared spectrometer, which tells you the frequencies that are absorbed by the sample. This provides important information about the functional groups present in the sample. This is exactly what FT-IR does.

As FT-IR can be used to get information about functional groups present in nanomaterials. This is particularly useful in cases such as when one attempts to surface modify nanomaterials to increase affinity, reactivity or compatibility. Analyzing the FT-IR of a nanomaterial would tell you what groups present and then appropriate surface modification strategy be decided based on the groups present. Further, it can also be useful in characterizing the surface modification has taken place, as new groups should emerge if the reaction is successful.

Terahertz Spectroscopy

Raman Spectroscopy

Surface Enhanced Raman Spectroscopy (SERS)

- Surface Enhanced Raman Spectroscopy (SERS)

- Surface-enhanced Raman spectroscopy: a brief retrospective

References

See also notes on editing this book Nanotechnology/About#How_to_contribute.

- ↑ Confocal laser scanning microscopy, Paddock SW, Biotechniques , vol. 27 (5): 992 NOV 1999

- ↑ A new UV-visible confocal laser scanning microspectrofluorometer designed for spectral cellular imaging, Favard C, Valisa P, Egret-Charlier M, Sharonov S, Herben C, Manfait M, Da Silva E, Vigny P, Biospectroscopy , vol. 5 (2): 101-115 1999

Electron Microscopy

| Navigate |

|---|

| << Prev: Optical Methods |

| >< Main: Nanotechnology |

| >> Next: Scanning Probe Microscopy |

Electron microscopy

An overview:

Electron microscopes uses electrons instead of photons, because electrons have a much shorter wavelength than photons and so allows you to observe matter with atomic resolution.

There are two general types of electron microscopes: the Scanning Electron Microscope (SEM) that scans an electron beam over the surface of an object and measures how many electrons are scattered back, and the Transmission Electron Microscope (TEM) that shoots electrons through the sample and measures how the electron beam changes because it is scattered in the sample.

Using electron beams however requires working in a vacuum environment, and this makes the instruments considerably larger and expensive. All electron microscope work under at least low pressures and usually in high vacuum chambers to avoid scattering the electrons in the gas. In environmental electron microscopes, differential pumping systems are used to actually have gasses present by the sample together with the electron beam.

Introduction to Electron Microscopy

For imaging of nanoscale objects, optical microscopy has limited resolution since the objects are often much smaller than the wavelength of light. The achievable resolution for a wavelength is often given by the diffraction limit as

- (r.g., diffraction limit)

with numerical aperture , which can be approximated by the largest angle of incidence of the wavefront towards the sample, .

Since for the present purposes, we can approximate and hence where is the radius of the objective lens aperture and the working distance.

Optical microscopes can often reach a resolution of about nm. For nanoscale resolution this is unfortunately not sufficient to distinguish for instance a single nanotube from two adhering to each other, since they have diameters of less than 100 nm.

The figure below gives an overview typical magnifications achievable by the different electron microscopes compared to a light microscope.

Electron optical systems use electrical and magnetic fields to control the electron beam. Although the law of refraction in optics is exchanged with the Lorentz force in electrodynamics, the electron optical system has similar diffraction limits as optical systems, since they depend on the wave nature of the electron beam.

One can achieve a considerable improvement in resolution with instruments such as the transmission electron microscope and the scanning electron microscope that use electrons with De Broglie wavelength much smaller than that of visible light. The De Broglie wavelength λ of an electron with momentum p is

- (Eq. De Broglie wavelength)

where is Plancks constant. The electron has rest mass and energy .

If an electron with charge is accelerated from rest by an electrical potential , to the electron beam energy , it will have a wavelength of 1 nm at 1 eV decreasing to 1 pm at 100 keV where it will be travelling with 50% the speed of light.

This chapter will briefly review fundamental issues for electron microscopy that are similar for SEM and TEM: the limitations imposed by the electron optical beam system in the microscope column; the interaction of the electron beam with the sample; the standard image formation method in SEM and TEM. These issues are essential to understand the results and limitations reached in SEM and TEM microscopy.

For further details, please refer to reviews of electron microscopes and their applications, such as Goldstein et al. [1] that contains a thorough review of SEM, while Goodhew and Humphreys [2] is a more general introduction to both SEM and TEM.

The Electron Optical System

For high resolution imaging, a well focused beam is required, just as in optical microscopy. Due to the short wavelength of electron beams with keV energies, as given by the #Eq de Broglie wavelength, the properties of the electron optical system and the electron emitter mainly defines the limits on the achievable beam diameter. The current density in the electron beam can be approximated by a Gaussian distribution of current density j [A/m²] as function of radius, r, from the beam center

with radius determined by , giving a the full width half maximum . Integrating gives the total beam current

The electron optics impose a limit on the achievable beam current density and radius by the brightness of the electron emitter , which is conserved throughout the system [3].

Brightness, ß, is a measure of the current per area normal to the beam direction and per element of solid angle [4]. At the center of the Gaussian beam,

and the brightness is related to the current density in eq SEM Gaussian beam profile. The emitter brightness is determined by the type of electron emitter and the beam energy [5]

with emission current density for W-filament sources about ~3 A/cm², for LaB6 sources about 100 A/cm², while field emission guns (FEG) can reach 105A/cm². The energy spread of the electrons from the sources are about ΔE~1 eV and slightly lower for FEGs. Due to conservation of the brightness in the system, the beam diameter depends on current as

The ideal beam probe size determined by the conservation of brightness cannot be obtained in a real system. Effects such as aberration will make the minimum achievable beam diameter larger. Equation #eq SEM beam diameter however seem to adequately describe the beam diameter for the present discussion. Apart from the additional beam widening contributions, the image detection method imposes limits on useful values for the parameters in Eq. SEM beam diameter which differ for SEM and TEM.

Electron Range

The electron optical system sets limitations to the achievable primary beam current and radius. The expected image resolution set by the primary beam cannot be reached if the signal detected for imaging is caused by electrons scattered far in the sample. The trajectory of an electron penetrating a bulk solid is a complex trajectory due to multiple elastic and inelastic collision events. As the primary electron (PE) penetrates into the sample it will gradually change direction and loose energy in collisions. The mean free path due to elastic and inelastic collisions, , depends on the atomic number of the material and the PE energy. At 100 keV for carbon and 5 nm for gold [6]. For samples thinner than the main part of the PE will pass relatively unaffected through the sample, which is the basis for TEM.

SEM can be used for thicker specimens. The electrons that escape from the sample in a new direction compared to the PE due to elastic collisions are called backscattered electrons (BSE).

For samples thicker than , the volume interacting with the scattered PE defines the range of the electrons in the material, and this is considerably larger than the minimum achievable primary beam diameters.

The electron range is about 1 µm at 10 keV for carbon, decreasing with higher atomic number for the material. Both the high energy PE and BSE generate secondary electrons (SE) by inelastic scattering events. The SE are generally defined as having energy below 50 eV while the BSE have energies up to the PE energy. The range of SE is typically 1 nm for metals and about 10 nm for insulators [7].

The short range of the SE make the yield of SE highly dependent on the energy lost by the PE within the SE range from the surface, and this makes high Z substances efficient generators of SE. The main emission of SE takes place in the region where the PE strikes the surface and within the SE escape depth from this region.

Scanning electron microscopy (SEM)

- Wikipedia: Scanning electron microscopy (SEM)

In a scanning electron microscope a beam is scanned over the sample surface in a raster pattern while a signal is recorded from electron detectors for SE or BSE. The PE energy is kept relatively low (1-30 keV) to limit the interaction volume in the specimen that will contribute to the detected signal. Especially low energy PE will provide high sensitivity to surface composition as they cannot penetrate far into the sample.

The figure above showed the effect of PE penetration depth of a carbonaceous nanostructure with a gold core, where only the surface is visible at low PE energies, while the carbon becomes increasingly transparent and the core visible at high PE energies.

The low energy SE can easily be attracted and collected by a positively charged detector and are hence an efficient source for an image signal. The standard SE detector is an Everhart-Thornley (ET) detector where a positively charged grid attracts the SE and accelerates them to sufficiently high energies to create a light pulse when striking a scintillator. The light pulse is then amplified by a photomultiplier. Despite the complex construction, the ET detector is remarkably efficient, but requires large for effective collection of the SE by the charged grid.

Another SEM detector is the in-lens detector, where SE passing through the column aperture are accelerated towards a solid state detector. The in-lens detector complements the ET by being more efficient at short .

Environmental SEM (ESEM)

The ESEM makes it possible to use various gasses in the sample chamber of the microscope since there are narrow apertures between the sample chamber and the gun column, and a region in between that is connected to a differential pumping system. Pressures up to about 10 Torr are normally possible in the sample chamber.

The standard Everly-Thornhart SE detector would not work under such conditions since it would create a discharge in the low pressure gas. Instead a "gaseous secondary electron detector (GSD)" is used, as shown in the figure below. The GSD measures the current of a weak cascade discharge in the gas, which is seeded by the emission of electrons from the sample.

In the ESEM one can work with for instance water vapour or argon as the environmental gas, and it is possible to have liquid samples in the chamber if the sample stage is cooled sufficiently to condense water.

Transmission electron microscopy (TEM)

When the specimen thickness is about the mean free path, , TEM can be used to achieve high resolution images such as the image above where the atomic lattice of a gold nanocrystal is visible. Since the detected electrons are transmitted PE where the energy can be in the 100 keV range, the resolution is not limited by the issues regarding secondary electrons. The electron beam optics can be optimized for higher current densities (Eq. #eq SEM current density) at higher energies compared to SEM.

To achieve optimal imaging conditions for the thin TEM samples, the working distance has been made short. In most TEMs, the space for the sample holder is only about (5 mm)³ between the two objective lenses for the incoming and transmitted beam. Before reaching a CCD camera, the transmitted beam is sent through several magnification lenses to achieve the high magnification (500.000X is not unusual).

The image formation in TEM can be based on several principles, but practically all images used in this work were made by phase contrast imaging, here called High Resolution TEM or HRTEM. At sufficiently high brightness, electron sources can produce coherent electron beams due to the point-like emitter surface area and small energy spread [8]. The coherent electron beam can be considered as a spherical wave propagating from the emitter and out through the electron optical system, much like a laser beam would propagate through an optical system.

The HRTEM images are often based on the interference of the electron wavefront after it has passed through the sample and reaches a CCD detector to give a phase contrast image of the sample. The image will have a resolution determined of course by the wavelength of the electrons (Eq. #eq SEM de broglie wavelength) but mainly by the imperfections of the electron optics which also perturbs the wavefront. The optimal imaging condition is for a sample thickness about , where the wavefront is only slightly perturbed by passing through the sample. TEM instruments are normally easily capable of resolving individual shells of a carbon nanotubes. The fine-tuning of the electron optical system to the required resolution can be achieved in about 30 min for many microscopes.

Electron Holography

In special TEM microscopes, the diffracted beam can be combined with a part of the original electron beam from the electron gun, and the image that is recorded is an interference pattern that depends on how much the phase of the diffracted beam was changed. By recording such images, one can measure how the electron wave function changes as it passes through or nearby a nanostructure - and this allows you to measure the electric and magnetic fields surrounding nanostructures.

Electron Tomography

By recording numerous TEM images of an object at many different angles, these images can in a computer be combined to create a three-dimensional model of the object. The technique is time consuming but allows you to see nanostructures in 3D.

References

- ↑ J. Goldstein, D. Newbury, P. Echlin, D. C. Joy, A. D. Romig, C. E. Lyman, C. Fiori, and E. Lifshin. Scanning Electron Microscopy and X-Ray Microanalysis, 2nd Ed. Plenum Press, 1992.

- ↑ P. J. Goodhew and F. J. Humphreys. Electron Microscopy and Analysis, 2rd Ed. Taylor and Francis, 1988.

- ↑ S. Humphries. Charged Particle Beams. John Wiley and Sons, 1990. PDF version available at http://www.fieldp.com/cpb/cpb.html.

- ↑ P. W. Hawkes and E. Kasper. Principles Of Electron Optics. Academic Press, 1989.

- ↑ L. Reimer. Transmission electron microscopy: Physics of image formation and microanalysis, 3rd Ed. Springer-Verlag, 1993.

- ↑ P. J. Goodhew and F. J. Humphreys. Electron Microscopy and Analysis, 2rd Ed. Taylor and Francis, 1988.

- ↑ J. Goldstein, D. Newbury, P. Echlin, D. C. Joy, A. D. Romig, C. E. Lyman, C. Fiori, and E. Lifshin. Scanning Electron Microscopy and X-Ray Microanalysis, 2nd Ed. Plenum Press, 1992.

- ↑ P. W. Milonni and J. H. Eberly. Lasers. John Wiley & Sons, Inc., 1988.

Scanning probe microscopy

| Navigate |

|---|

| << Prev: Electron Microscopy |

| >< Main: Nanotechnology |

| >> Next: Additional Methods |

|

|

| Section on AFM |

| Section on STM |

| Section on SNOM |

Scanning probe microscopy

Scanning probe microscopy covers the methods where a sharp tip is scanned over a surface in a raster pattern and the interaction with the surface is recorded in each pixel to form an image of the interaction. There are a multitude of methods and interactions in SPM. Broadly speaking, there are three main categories:

- In scanning tunneling microscopy (STM), one uses an atomically sharp metallic tip and records the minute tunneling current between the tip and the surface, when the tip is hovering so close to the surface that electrons can move between the surface and the tip.

- In Atomic force microscopy (AFM), a cantilever with a sharp tip - somewhat like the needle of an old record player - is scanned over the surface and the topography or surface softness can be recorded.