Engineering Acoustics/Print version

| This is the print version of Engineering_Acoustics You won't see this message or any elements not part of the book's content when you print or preview this page. |

Note: current version of this book can be found at http://en.wikibooks.org/wiki/Engineering_Acoustics

Remember to click "refresh" to view this version.

Part 1: Lumped Acoustical Systems

Simple Oscillation

The Position Equation

This section shows how to form the equation describing the position of a mass on a spring.

For a simple oscillator consisting of a mass m attached to one end of a spring with a spring constant s, the restoring force, f, can be expressed by the equation

where x is the displacement of the mass from its rest position. Substituting the expression for f into the linear momentum equation,

where a is the acceleration of the mass, we can get

or,

Note that the frequency of oscillation is given by

To solve the equation, we can assume

The force equation then becomes

Giving the equation

Solving for

This gives the equation of x to be

Note that

and that C1 and C2 are constants given by the initial conditions of the system

If the position of the mass at t = 0 is denoted as x0, then

and if the velocity of the mass at t = 0 is denoted as u0, then

Solving the two boundary condition equations gives

The position is then given by

This equation can also be found by assuming that x is of the form

And by applying the same initial conditions,

This gives rise to the same position equation

Alternate Position Equation Forms

If A1 and A2 are of the form

Then the position equation can be written

By applying the initial conditions (x(0)=x0, u(0)=u0) it is found that

If these two equations are squared and summed, then it is found that

And if the difference of the same two equations is found, the result is that

The position equation can also be written as the Real part of the imaginary position equation

Due to euler's rule (ejφ = cosφ + jsinφ), x(t) is of the form

- Example 1.1

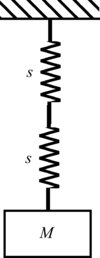

GIVEN: Two springs of stiffness, , and two bodies of mass,

FIND: The natural frequencies of the systems sketched below

Forced Oscillations(Simple Spring-Mass System)

Recap of Section 1.3

In the previous section, we discussed how adding a damping component (e. g. a dashpot) to an unforced, simple spring-mass system would affect the response of the system. In particular, we learned that adding the dashpot to the system changed the natural frequency of the system from to a new damped natural frequency , and how this change made the response of the system change from a constant sinusoidal response to an exponentially-decaying sinusoid in which the system either had an under-damped, over-damped, or critically-damped response.

In this section, we will digress a bit by going back to the simple (undamped) oscillator system of the previous section, but this time, a constant force will be applied to this system, and we will investigate this system’s performance at low and high frequencies as well as at resonance. In particular, this section will start by introducing the characteristics of the spring and mass elements of a spring-mass system, introduce electrical analogs for both the spring and mass elements, learn how these elements combine to form the mechanical impedance system, and reveal how the impedance can describe the mechanical system’s overall response characteristics. Next, power dissipation of the forced, simple spring-mass system will be discussed in order to corroborate our use of electrical circuit analogs for the forced, simple spring-mass system. Finally, the characteristic responses of this system will be discussed, and a parameter called the amplification ratio (AR) will be introduced that will help in plotting the resonance of the forced, simple spring-mass system.

Forced Spring Element

Taking note of Figs. 1, we see that the equation of motion for a spring that has some constant, external force being exerted on it is...

where is the mechanical stiffness of the spring.

Note that in Fig. 1(c), force flows constantly (i.e. without decreasing) throughout a spring, but the velocity of the spring decrease from to as the force flows through the spring. This concept is important to know because it will be used in subsequent sections.

In practice, the stiffness of the spring , also called the spring constant, is usually expressed as , or the mechanical compliance of the spring. Therefore, the spring is very stiff if is large is small. Similarly, the spring is very loose or “bouncy” if is small is large. Noting that force and velocity are analogous to voltage and current, respectively, in electrical systems, it turns out that the characteristics of a spring are analogous to the characteristics of a capacitor in relation to, and, so we can model the “reactiveness” of a spring similar to the reactance of a capacitor if we let as shown in Fig. 2 below.

Forced Mass Element

Taking note of Fig. 3, the equation for a mass that has constant, external force being exerted on it is...

If the mass can vary its value and is oscillating in a mechanical system at max amplitude such that the input the system receives is constant at frequency , as increases, the harder it will be for the system to move the mass at at until, eventually, the mass doesn’t oscillate at all . Another equivalently way to look at it is to let vary and hold constant. Similarly, as increases, the harder it will be to get to oscillate at and keep the same amplitude until, eventually, the mass doesn’t oscillate at all. Therefore, as increases, the “reactiveness” of mass decreases (i.e. starts to move less and less). Recalling the analogous relationship of force/voltage and velocity/current, it turns out that the characteristics of a mass are analogous to an inductor. Therefore, we can model the “reactiveness” of a mass similar to the reactance of an inductor if we let as shown in Fig. 4.

Mechanical Impedance of Spring-Mass System

As mentioned twice before, force is analogous to voltage and velocity is analogous to current. Because of these relationships, this implies that the mechanical impedance for the forced, simple spring-mass system can be expressed as follows:

In general, an undamped, spring-mass system can either be “spring-like” or “mass-like”. “Spring-like” systems can be characterized as being “bouncy” and they tend to grossly overshoot their target operating level(s) when an input is introduced to the system. These type of systems relatively take a long time to reach steady-state status. Conversely, “mass-like” can be characterized as being “lethargic” and they tend to not reach their desired operating level(s) for a given input to the system...even at steady-state! In terms of complex force and velocity, we say that “ force LEADS velocity” in mass-like systems and “velocity LEADS force” in spring-like systems (or equivalently “ force LAGS velocity” in mass-like systems and “velocity LAGS force” in spring-like systems). Figs. 5 shows this relationship graphically.

Power Transfer of a Simple Spring-Mass System

From electrical circuit theory, the average complex power dissipated in a system is expressed as ...

where and represent the (time-invariant) complex voltage and complex conjugate current, respectively. Analogously, we can express the net power dissipation of the mechanical system in general along with the power dissipation of a spring-like system or mass-like system as...

In equations 1.4.7, we see that the product of complex force and velocity are purely imaginary. Since reactive elements, or commonly called, lossless elements, cannot dissipate energy, this implies that the net power dissipation of the system is zero. This means that in our simple spring-mass system, power can only be (fully) transferred back and forth between the spring and the mass. But this is precisely what a simple spring-mass system does. Therefore, by evaluating the power dissipation, this corroborates the notion of using electrical circuit elements to model mechanical elements in our spring-mass system.

Responses For Forced, Simple Spring-Mass System

Fig. 6 below illustrates a simple spring-mass system with a force exerted on the mass.

This system has response characteristics similar to that of the undamped oscillator system, with the only difference being that at steady-state, the system oscillates at the constant force magnitude and frequency versus exponentially decaying to zero in the unforced case. Recalling equations 1.4.2b and 1.4.4b, letting be the natural (resonant) frequency of the spring-mass system, and letting be frequency of the input received by the system, the characteristic responses of the forced spring-mass systems are presented graphically in Figs. 7 below.

Amplification Ratio

The amplification ratio is a useful parameter that allows us to plot the frequency of the spring-mass system with the purports of revealing the resonant freq of the system solely based on the force experienced by each, the spring and mass elements of the system. In particular, AR is the magnitude of the ratio of the complex force experienced by the spring and the complex force experienced by the mass, i.e.

If we let , be the frequency ratio, it turns out that AR can also be expressed as...

AR will be at its maximum when . This happens precisely when . An example of an AR plot is shown below in Fig 8.

Mechanical Resistance

Mechanical Resistance

For most systems, a simple oscillator is not a very accurate model. While a simple oscillator involves a continuous transfer of energy between kinetic and potential form, with the sum of the two remaining constant, real systems involve a loss, or dissipation, of some of this energy, which is never recovered into kinetic nor potential energy. The mechanisms that cause this dissipation are varied and depend on many factors. Some of these mechanisms include drag on bodies moving through the air, thermal losses, and friction, but there are many others. Often, these mechanisms are either difficult or impossible to model, and most are non-linear. However, a simple, linear model that attempts to account for all of these losses in a system has been developed.

Dashpots

The most common way of representing mechanical resistance in a damped system is through the use of a dashpot. A dashpot acts like a shock absorber in a car. It produces resistance to the system's motion that is proportional to the system's velocity. The faster the motion of the system, the more mechanical resistance is produced.

As seen in the graph above, a linear relationship is assumed between the force of the dashpot and the velocity at which it is moving. The constant that relates these two quantities is , the mechanical resistance of the dashpot. This relationship, known as the viscous damping law, can be written as:

Also note that the force produced by the dashpot is always in phase with the velocity.

The power dissipated by the dashpot can be derived by looking at the work done as the dashpot resists the motion of the system:

Modeling the Damped Oscillator

In order to incorporate the mechanical resistance (or damping) into the forced oscillator model, a dashpot is placed next to the spring. It is connected to the mass () on one end and attached to the ground on the other end. A new equation describing the forces must be developed:

It's phasor form is given by the following:

Mechanical Impedance for Damped Oscillator

Previously, the impedance for a simple oscillator was defined as . Using the above equations, the impedance of a damped oscillator can be calculated:

For very low frequencies, the spring term dominates because of the relationship. Thus, the phase of the impedance approaches for very low frequencies. This phase causes the velocity to "lag" the force for low frequencies. As the frequency increases, the phase difference increases toward zero. At resonance, the imaginary part of the impedance vanishes, and the phase is zero. The impedance is purely resistive at this point. For very high frequencies, the mass term dominates. Thus, the phase of the impedance approaches and the velocity "leads" the force for high frequencies.

Based on the previous equations for dissipated power, we can see that the real part of the impedance is indeed . The real part of the impedance can also be defined as the cosine of the phase times its magnitude. Thus, the following equations for the power can be obtained.

Characterizing Damped Mechanical Systems

Characterizing Damped Mechanical Systems

Characterizing the response of Damped Mechanical Oscillating system can be easily quantified using two parameters. The system parameters are the resonance frequency ( and the damping of the system . In practice, finding these parameters would allow for quantification of unknown systems and allow you to derive other parameters within the system.

Using the mechanical impedance in the following equation, notice that the imaginary part will equal zero at resonance.

()

Resonance case:()

Calculating the Mechanical Resistance

The decay time of the system is related to 1 / B where B is the Temporal Absorption. B is related to the mechancial resistance and to the mass of the system by the following equation.

The mechanical resistance can be derived from the equation by knowing the mass and the temporal absorption.

Critical Damping

The system is said to be critically damped when:

A critically damped system is one in which an entire cycle is never completed. The absorption coefficient in this type of system equals the natural frequency. The system will begin to oscillate, however the amplitude will decay exponentially to zero within the first oscillation.

Damping Ratio

The damping ratio is a comparison of the mechanical resistance of a system to the resistance value required for critical damping. Rc is the value of Rm for which the absorption coefficient equals the natural frequency (critical damping). A damping ratio equal to 1 therefore is critically damped, because the mechanical resistance value Rm is equal to the value required for critical damping Rc. A damping ratio greater than 1 will be overdamped, and a ratio less than 1 will be underdamped.

Quality Factor

The Quality Factor (Q) is way to quickly characterize the shape of the peak in the response. It gives a quantitative representation of power dissipation in an oscillation.

Wu and Wl are called the half power points. When looking at the response of a system, the two places on either side of the peak where the point equals half the power of the peak power defines Wu and Wl. The distance in between the two is called the half-power bandwidth. So, the resonant frequency divided by the half-power bandwidth gives you the quality factor. Mathematically, it takes Q/pi oscillations for the vibration to decay to a factor of 1/e of its original amplitude.

Electro-Mechanical Analogies

Why Circuit Analogs?

Acoustic devices are often combinations of mechanical and electrical elements. A common example of this would be a loudspeaker connected to a power source. It is useful in engineering applications to model the entire system with one method. This is the reason for using a circuit analogy in a vibrating mechanical system. The same analytic method can be applied to Electro-Acoustic Analogies.

How Electro-Mechanical Analogies Work

An electrical circuit is described in terms of its potential (voltage) and flux (current). To construct a circuit analog of a mechanical system we define flux and potential for the system. This leads to two separate analog systems. The Impedance Analog denotes the force acting on an element as the potential and the velocity of the element as the flux. The Mobility Analog equates flux with the force and velocity with potential.

| Mechanical | Electrical Equivalent | |

|---|---|---|

| Impedance Analog | ||

| Potential: | Force | Voltage |

| Flux: | Velocity | Current |

| Mobility Analog | ||

| Potential: | Velocity | Voltage |

| Flux: | Force | Current |

For many, the mobility analog is considered easier for a mechanical system. It is more intuitive for force to flow as a current and for objects oscillating the same frequency to be wired in parallel. However, either method will yield equivalent results and can also be translated using the dual (dot) method.

The Basic Elements of an Oscillating Mechanical System

The Mechanical Spring:

The ideal spring is considered to be operating within its elastic limit, so the behavior can be modeled with Hooke's Law. It is also assumed to be massless and have no damping effects.

The Mechanical Mass

In a vibrating system, a mass element opposes acceleration. From Newton's Second Law:

The Mechanical Resistance

The dashpot is an ideal viscous damper which opposes velocity.

Ideal Generators

The two ideal generators which can drive any system are an ideal velocity and ideal force generator. The ideal velocity generator can be denoted by a drawing of a crank or simply by declaring , and the ideal force generator can be drawn with an arrow or by declaring

Simple Damped Mechanical Oscillators

In the following sections we will consider this simple mechanical system as a mobility and impedance analog. It can be driven either by an ideal force or an ideal velocity generator, and we will consider simple harmonic motion. The m in the subscript denotes a mechanical system, which is currently redundant, but can be useful when combining mechanical and acoustic systems.

The Impedance Analog

The Mechanical Spring

In a spring, force is related to the displacement from equilibrium. By Hooke's Law,

The equivalent behaviour in a circuit is a capacitor:

The Mechanical Mass

The force on a mass is related to the acceleration (change in velocity). The behaviour, by Newton's Second Law, is:

The equivalent behaviour in a circuit is an inductor:

The Mechanical Resistance

For a viscous damper, the force is directly related to the velocity

The equivalent is a simple resistor of value

Example:

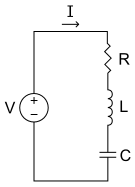

Thus the simple mechanical oscillator in the previous section becomes a series RCL Circuit:

The current through all three elements is equal (they are at the same velocity) and that the sum of the potential drops across each element will equal the potential at the generator (the driving force). The ideal voltage generator depicted here would be equivalent to an ideal force generator.

IMPORTANT NOTE: The velocity measured for the spring and dashpot is the relative velocity ( velocity of one end minus the velocity of the other end). The velocity of the mass, however, is the absolute velocity.

Impedances:

| Element | Impedance | |

|---|---|---|

| Spring | Capacitor | |

| Mass | Inductor | |

| Dashpot | Resistor |

The Mobility Analog

Like the Impedance Analog above, the equivalent elements can be found by comparing their fundamental equations with the equations of circuit elements. However, since circuit equations usually define voltage in terms of current, in this case the analogy would be an expression of velocity in terms of force, which is the opposite of convention. However, this can be solved with simple algebraic manipulation.

The Mechanical Spring

The equivalent behavior for this circuit is the behavior of an inductor.

The Mechanical Mass

Similar to the spring element, if we take the general equation for a capacitor and differentiate,

The Mechanical Resistance

Since the relation between force and velocity is proportionate, the only difference is that the mechanical resistance becomes inverted:

Example:

The simple mechanical oscillator drawn above would become a parallel RLC Circuit. The potential across each element is the same because they are each operating at the same velocity. This is often the more intuitive of the two analogy methods to use, because you can visualize force "flowing" like a flux through your system. The ideal voltage generator in this drawing would correspond to an ideal velocity generator.

IMPORTANT NOTE: Since the measure of the velocity of a mass is absolute, a capacitor in this analogy must always have one terminal grounded. A capacitor with both terminals at a potential other than ground may be realized physically as an inverter, which completes all elements of this analogy.

Impedances:

| Element | Impedance | |

|---|---|---|

| Spring | Inductor | |

| Mass | Capacitor | |

| Dashpot | Resistor |

Methods for checking Electro-Mechanical Analogies

After drawing the electro-mechanical analogy of a mechanical system, it is always safe to check the circuit. There are two methods to accomplish this:

Review of Circuit Solving Methods

Kirchkoff's Voltage law

"The sum of the potential drops around a loop must equal zero."

Kirchkoff's Current Law

"The Sum of the currents at a node (junction of more than two elements) must be zero"

Hints for solving circuits:

Remember that certain elements can be combined to simplify the circuit (the combination of like elements in series and parallel)

If solving a circuit that involves steady-state sources, use impedances. Any circuit can eventually be combined into a single impedance using the following identities:

Impedances in series:

Impedances in parallel:

Dot Method: (Valid only for planar network)

This method helps obtain the dual analog (one analog is the dual of the other). The steps for the dot product are as follows:

1) Place one dot within each loop and one outside all the loops.

2) Connect the dots. Make sure that there is only one line through each element and that no lines cross more than one element.

3) Draw in each line that crosses an element its dual element, including the source.

4) The circuit obtained should have an equivalent behavior as the dual analog of the original electro-mechanical circuit.

Example:

The parallel RLC Circuit above is equivalent to a series RLC driven by an ideal current source

Low-Frequency Limits

This method looks at the behavior of the system for very large or very small values of the parameters and compares them with the expected behavior of the mechanical system. For instance, you can compare the mobility circuit behavior of a near-infinite inductance with the mechanical system behavior of a near-infinite stiffness spring.

| Very High Value | Very Low Value | |

|---|---|---|

| Capacitor | Short Circuit | Open Circuit |

| Inductor | Open Circuit | Closed Circuit |

| Resistor | Open Circuit | Short Circuit |

Additional Resources for solving linear circuits

Thomas & Rosa, "The Analysis and Design of Linear Circuits", Wiley, 2001

Hayt, Kemmerly & Durbin, "Engineering Circuit Analysis", 6th ed., McGraw Hill, 2002

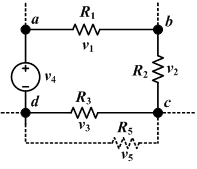

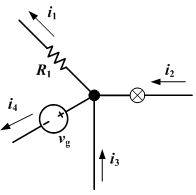

Examples of Electro-Mechanical Analogies

Example of Electro-Mechanical Analogies

Note: The crank indicates an ideal velocity generator, with an amplitude of rotating at rad/s.

Impedance Analog Solution

Mobility Analog Solution

Primary variables of interest

Basic Assumptions

Consider a piston moving in a tube. The piston starts moving at time t=0 with a velocity u=. The piston fits inside the tube smoothly without any friction or gap. The motion of the piston creates a planar sound wave or acoustic disturbance traveling down the tube at a constant speed c>>. In a case where the tube is very small, one can neglect the time it takes for acoustic disturbance to travel from the piston to the end of the tube. Hence, one can assume that the acoustic disturbance is uniform throughout the tube domain.

Assumptions

1. Although sound can exist in solids or fluid, we will first consider the medium to be a fluid at rest. The ambient, undisturbed state of the fluid will be designated using subscript zero. Recall that a fluid is a substance that deforms continuously under the application of any shear (tangential) stress.

2. Disturbance is a compressional one (as opposed to transverse).

3. Fluid is a continuum: infinitely divisible substance. Each fluid property assumed to have definite value at each point.

4. The disturbance created by the motion of the piston travels at a constant speed. It is a function of the properties of the ambient fluid. Since the properties are assumed to be uniform (the same at every location in the tube) then the speed of the disturbance has to be constant. The speed of the disturbance is the speed of sound, denoted by letter with subscript zero to denote ambient property.

5. The piston is perfectly flat, and there is no leakage flow between the piston and the tube inner wall. Both the piston and the tube walls are perfectly rigid. Tube is infinitely long, and has a constant area of cross section, A.

6. The disturbance is uniform. All deviations in fluid properties are the same across the tube for any location x. Therefore the instantaneous fluid properties are only a function of the Cartesian coordinate x (see sketch). Deviations from the ambient will be denoted by primed variables.

Variables of interest

Pressure (force / unit area)

Pressure is defined as the normal force per unit area acting on any control surface within the fluid.

For the present case,inside a tube filled with a working fluid, pressure is the ratio of the surface force acting onto the fluid in the control region and the tube area. The pressure is decomposed into two components - a constant equilibrium component, , superimposed with a varying disturbance . The deviation is also called the acoustic pressure. Note that can be positive or negative. Unit: . Acoustical pressure can be measured using a microphone.

Density

Density is mass of fluid per unit volume. The density, ρ, is also decomposed into the sum of ambient value (usually around ρ0= 1.15 kg/m3) and a disturbance ρ’(x). The disturbance can be positive or negative, as for the pressure. Unit:

Acoustic volume velocity

Rate of change of fluid particles position as a function of time. Its the well known fluid mechanics term, flow rate.

In most cases, the velocity is assumed constant over the entire cross section (plug flow), which gives acoustic volume velocity as a product of fluid velocity and cross section S.

Electro-acoustic analogies

Electro-acoustical Analogies

Acoustical Mass

Consider a rigid tube-piston system as following figure.

Piston is moving back and forth sinusoidally with frequency of f. Assuming (where c is sound velocity ), volume of fluid in tube is,

Then mass (mechanical mass) of fluid in tube is given as,

For sinusoidal motion of piston, fluid move as rigid body at same velocity as piston. Namely, every point in tube moves with the same velocity.

Applying the Newton's second law to the following free body diagram,

Where, plug flow assumption is used.

"Plug flow" assumption:

Frequently in acoustics, the velocity distribution along the normal surface of

fluid flow is assumed uniform. Under this assumption, the acoustic volume velocity U is

simply product of velocity and entire surface.

Acoustical Impedance

Recalling mechanical impedance,

acoustical impedance (often termed an acoustic ohm) is defined as,

where, acoustical mass is defined.

Acoustical Mobility

Acoustical mobility is defined as,

Impedance Analog vs. Mobility Analog

Acoustical Resistance

Acoustical resistance models loss due to viscous effects (friction) and flow resistance (represented by a screen).

Acoustical Generators

The acoustical generator components are pressure, P and volume velocity, U, which are analogus to force, F and velocity, u of electro-mechanical analogy respectively. Namely, for impedance analog, pressure is analogous to voltage and volume velocity is analogus to current, and vice versa for mobility analog. These are arranged in the following table.

Impedance and Mobility analogs for acoustical generators of constant pressure and constant volume velocity are as follows:

Acoustical Compliance

Consider a piston in an enclosure.

When the piston moves, it displaces the fluid inside the enclosure. Acoustic compliance is the measurement of how "easy" it is to displace the fluid.

Here the volume of the enclosure should be assumed to be small enough that the fluid pressure remains uniform.

Assume no heat exchange 1.adiabatic 2.gas compressed uniformly , p prime in cavity everywhere the same.

from thermo equitation File:Equ1.jpg it is easy to get the relation between disturbing pressure and displacement of the piston File:Equ3.gif where U is volume rate, P is pressure according to the definition of the impendance and mobility, we can getFile:Equ4.gif

Mobility Analog VS Impedance Analog

Examples of Electro-Acoustical Analogies

Example 1: Helmholtz Resonator

Assumptions - (1) Completely sealed cavity with no leaks. (2) Cavity acts like a rigid body inducing no vibrations.

Solution:

Example 2: Combination of Side-Branch Cavities

Solution:

Transducers - Loudspeaker

Acoustic transducer

The purpose of an acoustic transducer is to convert electrical energy into acoustic energy. Many variations of acoustic transducers exist, such as electrostatic, balanced armature and moving-coil loudspeakers. This article focuses on moving-coil loudspeakers since they are the most commonly used type of acoustic transducer. First, the physical construction and principle of a typical moving coil transducer are discussed briefly. Second, electro-mechano-acoustical modeling of each element composing the loudspeaker is presented in a tutorial way to reinforce and supplement the theory on electro-mechanical analogies and electro-acoustic analogies previously seen in other sections. Third, the equivalent circuit is analyzed to introduce the theory behind Thiele-Small parameters, which are very useful when designing loudspeaker enclosures. A method to experimentally determine Thiele-Small parameters is also included.

Moving-coil loudspeaker construction and principle

The classic moving-coil loudspeaker driver can be divided into three key components:

1) The magnet motor drive system, comprising the permanent magnet, the center pole and the voice coil acting together to produce a mechanical force on the diaphragm from an electrical current.

2) The loudspeaker cone system, comprising the diaphragm and dust cap, permitting mechanical force to be translated into acoustic pressure;

3) The loudspeaker suspension, comprising the spider and surround, preventing the diaphragm from breaking due to over excursion, allowing only translational movement and tending to bring the diaphragm back to its rest position.

The following illustration shows a cut-away view of a typical moving coil-permanent magnet loudspeaker. A coil is mechanically coupled to a diaphragm, also called cone, and rests in a fixed magnetic field produced by a magnet. When an electrical current flows through the coil, a corresponding magnetic field is emitted, interacting with the fixed field of the magnet and thus applying a force to the coil, pushing it away or towards the magnet. Since the cone is mechanically coupled to the coil, it will push or pull the air it is facing, causing pressure changes and emitting a sound wave.

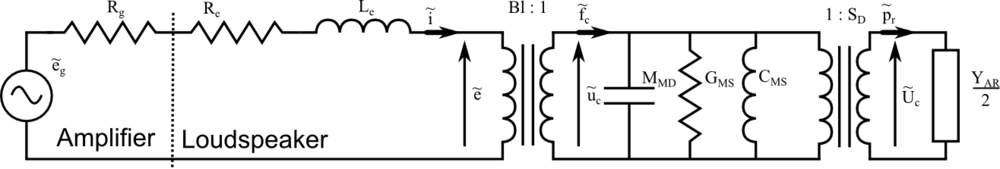

An equivalent circuit can be obtained to model the loudspeaker as a lumped system. This circuit can be used to drive the design of a complete loudspeaker system, including an enclosure and sometimes even an amplifier that is matched to the properties of the driver. The following section shows how such an equivalent circuit can be obtained.

Electro-mechano-acoustical equivalent circuit

Electro-mechanico-acoustical systems such as loudspeakers can be modeled as equivalent electrical circuits as long as each element moves as a whole. This is usually the case at low frequencies or at frequencies where the dimensions of the system are small compared to the wavelength of interest. To obtain a complete model of the loudspeaker, the interactions and properties of electrical, mechanical, and acoustical subsystems composing the loudspeaker driver must each be modeled. The following sections detail how the circuit may be obtained starting with the amplifier and ending with the acoustical load presented by air. A similar development can be found in [1] or [2].

Electrical subsystem

The electrical part of the system is composed of a driving amplifier and a voice coil. Most amplifiers can be approximated as a perfect voltage source in series with the amplifier output impedance. The voice coil exhibits an inductance and a resistance that may be directly modeled as a circuit.

Electrical to mechanical subsystem

When the loudspeaker is fed an electrical signal, the voice coil and magnet convert current to force. Similarly, voltage is related to the velocity. This relationship between the electrical side and the mechanical side can be modeled by a transformer.

;

Mechanical subsystem

In a first approximation, a moving coil loudspeaker may be thought of as a mass-spring system where the diaphragm and the voice coil constitute the mass and the spider and surround constitute the spring element. Losses in the suspension can be modeled as a resistor.

The equation of motion gives us :

Which yields the mechanical impedance type analogy in the form of a series RLC circuit. A parallel RLC circuit may also be obtained to get the mobility analog following mathematical manipulation:

Which expresses the mechanical mobility type analogy in the form of a parallel RLC circuit where the denominator elements are respectively a parallel conductance, inductance, and compliance.

Mechanical to acoustical subsystem

A loudspeaker’s diaphragm may be thought of as a piston that pushes and pulls on the air facing it, converting mechanical force and velocity into acoustic pressure and volume velocity. The equations are as follow:

;

These equations can be modeled by a transformer.

Acoustical subsystem

The impedance presented by the air load on the loudspeaker's diaphragm is both resistive due to sound radiation and reactive due to the air mass that is being pushed radially but does not contribute to sound radiation to the far field. The air load on the diaphragm can be modeled as an impedance or an admittance. Specific values and approximations can be found in [1], [2] or [3]. Note that the air load depends on the mounting conditions of the loudspeaker. If the loudspeaker is mounted in a baffle, the air load will be the same on each side of the diaphragm. Then, if the air load on one side is in the admittance analogy, then the total air load is as both loads are in parallel.

Complete electro-mechano-acoustical equivalent circuit

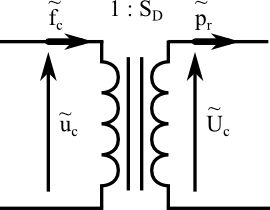

Using electrical impedance, mechanical mobility and acoustical admittance yield the following equivalent circuit, modeling the entire loudspeaker drive unit.

This circuit can be reduced by substituting the transformers and connected loads by an equivalent loading that would present the same impedance as the loaded transformer. An example of this is shown on figure 7, where acoustical and electrical loads and sources have been "brought over" to the mechanical side.

The advantage of doing such manipulations is that we can then directly relate electrical measurements with elements in the circuit. This will later allow us to obtain values for the different components of the model and match this model to real loudspeaker drivers. We can further simplify this circuit by using Norton's theorem and converting the series electrical components and voltage source into an equivalent current source and parallel electrical components. Then, using a technique called the Dot method, presented in section Solution Methods: Electro-Mechanical Analogies, we can obtain a single loop series circuit which is the dual of the parallel circuit previously obtained with Norton's theorem. If we are mainly interested in the low frequency behavior of the loudspeaker, as should be the case when using lumped element modeling, we can neglect the effect of the voice coil inductance, which has an effect only at high frequencies. Furthermore, the air load impedance at low frequencies is mass-like and can be modeled by a simple inductance . This results in a simplified low frequency model equivalent circuit, shown of figure 8, which is easier to manipulate than the circuit of figure 7. Note that the analogy used for this circuit is of the impedance type.

Where if is the radius of the loudspeaker and , the density of air. Mass elements, in this case the mass of the diaphragm and voice coil and the air mass loading the diaphragm can be regrouped in a single element:

Thiele-Small Parameters

Theory

The complete low frequency behavior of a loudspeaker drive unit can be modeled with just six parameters, called Thiele-Small parameters. Most of these parameters result from algebraic manipulation of the equations of the circuit of figure 8. Loudspeaker driver manufacturers seldom provide electro-mechano-acoustical parameters directly and rather provide Thiele-Small parameters in datasheets, but conversion from one to the other is quite simple. The Thiele-Small parameters are as follow:

1. , the voice coil DC resistance;

2. , the electrical Q factor;

3. , the mechanical Q factor;

4. , the loudspeaker resonance frequency;

5. , the effective surface area of the diaphragm;

6. , the equivalent suspension volume: the volume of air that has the same acoustic compliance as the suspension of the loudspeaker driver.

These parameters can be related directly from the low frequency approximation circuit of figure 8, with and being explicit.

; ; ;

Where is the Bulk modulus of air. It follows that, if given Thiele-Small parameters, one can extract the values of each component of the circuit of figure 8 using the following equations :

; ; ; ; ;

Measurement

Many methods can be used to measure Thiele-Small parameters of drivers. Measurement of Thiele-Small parameters is sometimes necessary if a manufacturer does not provide them. Also, the actual Thiele-Small parameters of a given loudspeaker can differ from nominal values significantly. The method described in this section comes from [2]. Note that for this method, the loudspeaker is considered to be mounted in an infinite baffle. In practice, a baffle with a diameter of four times that of the loudspeaker is sufficient. Measurements without a baffle are also possible: the air mass loading will simply be halved and can be easily accounted for. The setup for this method includes an FFT analyzer or a mean to obtain an impedance curve. A signal generator of variable frequency and an AC meter can also be used.

Once the impedance curve of the loudspeaker is measured, and can be directly identified by looking at the low frequency asymptote of the impedance value and the center frequency of the resonance peak. If the frequencies where are identified as and , Q factors can be calculated.

can simply be approximated by , where is the radius of the loudspeaker driver. The last remaining Thiele-Small parameter, is slightly trickier to measure. The idea is to either increase mass or reduce compliance of the loudspeaker drive unit and note the shift in resonance frequency. If a known mass is added to the loudspeaker diaphragm, the new resonance frequency will be:

And the equivalent suspension volume may be obtained with:

Hence, all Thiele-Small parameters modeling the low frequency behavior of the loudspeaker drive unit can be obtained from a fairly simple setup. These parameters are of tremendous help in loudspeaker enclosure design.

Numerical example

This section presents a numerical example of obtaining Thiele-Small parameters from impedance curves. The impedance curves presented in this section have been obtained from simulations using nominal Thiele-Small parameters of a real woofer loudspeaker. Firsy, these Thiele-Small parameters have been transformed into an electro-mechano-acoustical circuit using the equation presented before. Second, the circuit was treated as a black box and the method to extract Thiele-Small parameters was used. The purpose of this simulation is to present the method, step by step, using realistic values so that the reader can get more familiar with the process, the magnitude of the values and with what to expect when performing such measurements.

For this simulation, a loudspeaker of radius is mounted on a baffle sufficiently large to act as an infinite baffle. Its impedance is obtained and plotted in figure 11, where important cursors have already been placed.

The low frequency asymptote is immediately identified as . The resonance is clear and centered at . The value of the impedance at this frequency is about . This yields , which occurs at and . With this information, we can compute some of the Thiele-Small parameters.

As a next step, a mass of is fixed to the loudspeaker diaphragm. This shifts the resonance frequency and yields a new impedance curve, as shown on figure 12.

Once all six Thiele-Small parameters have been obtained, it is possible to calculate values for the electro-mechano-acoustical circuit modeling elements of figure 6 or 7. From then, the design of an enclosure can start. This is discussed in application sections Sealed box subwoofer design and Bass reflex enclosure design.

References

[1] Kleiner, Mendel. Electroacoustics. CRC Press, 2013.

[2] Beranek, Leo L., and Tim Mellow. Acoustics: sound fields and transducers. Academic Press, 2012.

[3] Kinsler, Lawrence E., et al. Fundamentals of Acoustics, 4th Edition. Wiley-VCH, 1999.

[4] Small, Richard H. "Direct radiator loudspeaker system analysis." Journal of the Audio Engineering Society 20.5 (1972): 383-395.

Moving Resonators

Moving Resonators

Consider the situation shown in the figure below. We have a typical Helmholtz resonator driven by a massless piston which generates a sinusoidal pressure , however the cavity is not fixed in this case. Rather, it is supported above the ground by a spring with compliance . Assume the cavity has a mass .

Recall the Helmholtz resonator (see Module #9). The difference in this case is that the pressure in the cavity exerts a force on the bottom of the cavity, which is now not fixed as in the original Helmholtz resonator. This pressure causes a force that acts upon the cavity bottom. If the surface area of the cavity bottom is , then Newton's Laws applied to the cavity bottom give

In order to develop the equivalent circuit, we observe that we simply need to use the pressure (potential across ) in the cavity to generate a force in the mechanical circuit. The above equation shows that the mass of the cavity and the spring compliance should be placed in series in the mechanical circuit. In order to convert the pressure to a force, the transformer is used with a ratio of .

Example

A practical example of a moving resonator is a marimba. A marimba is a similar to a xylophone but has larger resonators that produce deeper and richer tones. The resonators (seen in the picture as long, hollow pipes) are mounted under an array of wooden bars which are struck to create tones. Since these resonators are not fixed, but are connected to the ground through a stiffness (the stand), it can be modeled as a moving resonator. Marimbas are not tunable instruments like flutes or even pianos. It would be interesting to see how the tone of the marimba changes as a result of changing the stiffness of the mount.

For more information about the acoustics of marimbas see http://www.mostlymarimba.com/techno1.html

Part 2: One-Dimensional Wave Motion

Transverse vibrations of strings

Introduction

This section deals with the wave nature of vibrations constrained to one dimension. Examples of this type of wave motion are found in objects such a pipes and tubes with a small diameter (no transverse motion of fluid) or in a string stretched on a musical instrument.

Stretched strings can be used to produce sound (e.g. music instruments like guitars). The stretched string constitutes a mechanical system that will be studied in this chapter. Later, the characteristics of this system will be used to help to understand by analogies acoustical systems.

What is a wave equation?

There are various types of waves (i.e. electromagnetic, mechanical, etc.) that act all around us. It is important to use wave equations to describe the time-space behavior of the variables of interest in such waves. Wave equations solve the fundamental equations of motion in a way that eliminates all variables but one. Waves can propagate longitudinal or parallel to the propagation direction or perpendicular (transverse) to the direction of propagation. To visualize the motion of such waves click here (Acoustics animations provided by Dr. Dan Russell,Kettering University)

One dimensional Case

Assumptions :

- the string is uniform in size and density

- stiffness of string is negligible for small deformations

- effects of gravity neglected

- no dissipative forces like frictions

- string deforms in a plane

- motion of the string can be described by using one single spatial coordinate

Spatial representation of the string in vibration:

The following is the free-body diagram of a string in motion in a spatial coordinate system:

From the diagram above, it can be observed that the tensions in each side of the string will be the same as follows:

Using Taylor series to expand we obtain:

Characterization of the mechanical system

A one dimensional wave can be described by the following equation (called the wave equation):

where,

is a solution,

With and

This is the D'Alambert solution, for more information see: [1]

Another way to solve this equation is the Method of separation of variables. This is useful for modal analysis. This assumes the solution is of the form:

The result is the same as above, but in a form that is more convenient for modal analysis.

For more information on this approach see: Eric W. Weisstein et al. "Separation of Variables." From MathWorld—A Wolfram Web Resource. [2]

Please see Wave Properties for information on variable c, along with other important properties.

For more information on wave equations see: Eric W. Weisstein. "Wave Equation." From MathWorld—A Wolfram Web Resource. [3]

Example with the function :

Example: Java String simulation

This show a simple simulation of a plucked string with fixed ends.

Time-Domain Solutions

d'Alembert Solutions

In 1747, Jean Le Rond d'Alembert published a solution to the one-dimensional wave equation.

The general solution, now known as the d'Alembert method, can be found by introducing two new variables:

and

and then applying the chain rule to the general form of the wave equation.

From this, the solution can be written in the form:

where f and g are arbitrary functions, that represent two waves traveling in opposing directions.

A more detailed look into the proof of the d'Alembert solution can be found here.

Example of Time Domain Solution

If f(ct-x) is plotted vs. x for two instants in time, the two waves are the same shape but the second displaced by a distance of c(t2-t1) to the right.

The two arbitrary functions could be determined from initial conditions or boundary values.

Boundary Conditions and Forced Vibrations

Boundary Conditions

The functions representing the solutions to the wave equation previously discussed,

i.e. with and

are dependent upon the boundary and initial conditions. If it is assumed that the wave is propagating through a string, the initial conditions are related to the specific disturbance in the string at t=0. These specific disturbances are determined by location and type of contact and can be anything from simple oscillations to violent impulses. The effects of boundary conditions are less subtle.

The most simple boundary conditions are the Fixed Support and Free End. In practice, the Free End boundary condition is rarely encountered since it is assumed there are no transverse forces holding the string (e.g. the string is simply floating).

For a Fixed Support

The overall displacement of the waves travelling in the string, at the support, must be zero. Denoting x=0 at the support, This requires:

Therefore, the total transverse displacement at x=0 is zero.

The sequence of wave reflection for incident, reflected and combined waves are illustrated below. Please note that the wave is traveling to the left (negative x direction) at the beginning. The reflected wave is ,of course, traveling to the right (positive x direction).

For a Free Support

Unlike the Fixed Support boundary condition, the transverse displacement at the support does not need to be zero, but must require the sum of transverse forces to cancel. If it is assumed that the angle of displacement is small,

and so,

But of course, the tension in the string, or T, will not be zero and this requires the slope at x=0 to be zero:

i.e.

Again for free boundary, the sequence of wave reflection for incident, reflected and combined waves are illustrated below:

Other Boundary Conditions

There are many other types of boundary conditions that do not fall into our simplified categories. As one would expect though, it isn't difficult to relate the characteristics of numerous "complex" systems to the basic boundary conditions. Typical or realistic boundary conditions include mass-loaded, resistance-loaded, damping-loaded, and impedance-loaded strings. For further information, see Kinsler, Fundamentals of Acoustics, pp 54–58.

Here is a website with nice movies of wave reflection at different BC's: Wave Reflection

Wave Properties

To begin with, a few definitions of useful variables will be discussed. These include; the wave number, phase speed, and wavelength characteristics of wave travelling through a string.

The speed that a wave propagates through a string is given in terms of the phase speed, typically in m/s, given by:

where is the density per unit length of the string.

The wave number is used to reduce the transverse displacement equation to a simpler form and for simple harmonic motion, is multiplied by the lateral position. It is given by:

where

Lastly, the wavelength is defined as:

and is defined as the distance between two points, usually peaks, of a periodic waveform.

These "wave properties" are of practical importance when calculating the solution of the wave equation for a number of different cases. As will be seen later, the wave number is used extensively to describe wave phenomenon graphically and quantitatively.

For further information: Wave Properties

Forced Vibrations

1.forced vibrations of infinite string suppose there is a string very long , at x=0 there is a force exerted on it.

F(t)=Fcos(wt)=Real{Fexp(jwt)}

use the boundary condition at x=0,

neglect the reflected wave

it is easy to get the wave form

where w is the angular velocity, k is the wave number.

according to the impedance definition

it represents the characteristic impedance of the string. obviously, it is purely resistive, which is like the resistance in the mechanical system.

The dissipated power

Note: along the string, all the variables propagate at same speed.

link title a useful link to show the time-space property of the wave.

Some interesting animations of the wave at different boundary conditions.

1.hard boundary (which is like a fixed end)

2.soft boundary (which is like a free end)

3.from low density to high density string

4.from high density to low density string

Part 3: Applications

Room Acoustics and Concert Halls

Room Acoustics and Concert Halls

Introduction

From performing on many different rooms and stages all over the United States, I thought it would be nice to have a better understanding and source about the room acoustics. This Wikibook page is intended to help the user with basic technical questions/answers about room acoustics. Main topics that will be covered are: what really makes a room sound good or bad, alive or dead. This will lead into absorption and transmission coefficients, decay of sound in the room, and reverberation. Different use of materials in rooms will be mentioned also. There is no intention of taking work from another. This page is a switchboard source to help the user find information about room acoustics.

Sound Fields

Two types of sound fields are involved in room acoustics: Direct Sound and Reverberant Sound.

Direct Sound

The component of the sound field in a room that involves only a direct path between the source and the receiver, before any reflections off walls and other surfaces.

Reverberant Sound

The component of the sound field in a room that involves the direct path and the path after it reflects off of walls or any other surfaces. How the waves deflect off of the mediums all depends on the absorption and transmission coefficients.

Good example pictures are shown at Crutchfield Advisor, a Physics Site from MTSU, and Voiceteacher.com

Room Coefficients

In a perfect world, if there is a sound shot right at a wall, the sound should come right back. But because sounds hit different materials types of walls, the sound does not have perfect reflection. From 1, these are explained as follows:

Absorption & Transmission Coefficients

The best way to explain how sound reacts to different mediums is through acoustical energy. When sound impacts on a wall, acoustical energy will be reflected, absorbed, or transmitted through the wall.

Absorption Coefficient:  NB: this chemical structure is unrelated to the acoustics being discussed.

NB: this chemical structure is unrelated to the acoustics being discussed.

If all of the acoustic energy hits the wall and none is reflected, the alpha would equal 1. The energy had zero reflection and was absorbed or transmitted. This would be an example of a dead or soft wall because it takes in everything and doesn't reflect anything back. Rooms that are like this are called Anechoic Rooms which looks like this from Axiomaudio.

If all of the acoustic energy hits the wall and all reflects back, the alpha would equal 0. This would be an example of a live or hard wall because the sound bounces right back and does not go through the wall. Rooms that are like this are called Reverberant Rooms like this McIntosh room. Look how the walls have nothing attached to them. More room for the sound waves to bounce off the walls.

Room Averaged Sound Absorption Coefficient

Not all rooms have the same walls on all sides. The room averaged sound absorption coefficient can be used to have different types of materials and areas of walls averaged together.

Absorption Coefficients for Specific Materials

Basic sound absorption Coefficients are shown here at Acoustical Surfaces.

Brick, unglazed, painted alpha ~ .01 - .03 -> Sound reflects back

An open door alpha equals 1 -> Sound goes through

Units are in Sabins.

Sound Decay and Reverberation Time

In a large reverberant room, a sound can still propagate after the sound source has been turned off. This time when the sound intensity level has decay 60 dB is called the reverberation time of the room.

Great Halls in the World

Pick Staiger at Northwestern U

References

[1] Lord, Gatley, Evensen; Noise Control for Engineers, Krieger Publishing, 435 pgs

Back to Engineering Acoustics

Created by Kevin Baldwin

Bass Reflex Enclosure Design

Introduction

Bass-reflex enclosures improve the low-frequency response of loudspeaker systems. Bass-reflex enclosures are also called "vented-box design" or "ported-cabinet design". A bass-reflex enclosure includes a vent or port between the cabinet and the ambient environment. This type of design, as one may observe by looking at contemporary loudspeaker products, is still widely used today. Although the construction of bass-reflex enclosures is fairly simple, their design is not simple, and requires proper tuning. This reference focuses on the technical details of bass-reflex design. General loudspeaker information can be found here.

Effects of the Port on the Enclosure Response

Before discussing the bass-reflex enclosure, it is important to be familiar with the simpler sealed enclosure system performance. As the name suggests, the sealed enclosure system attaches the loudspeaker to a sealed enclosure (except for a small air leak included to equalize the ambient pressure inside). Ideally, the enclosure would act as an acoustical compliance element, as the air inside the enclosure is compressed and rarified. Often, however, an acoustic material is added inside the box to reduce standing waves, dissipate heat, and other reasons. This adds a resistive element to the acoustical lumped-element model. A non-ideal model of the effect of the enclosure actually adds an acoustical mass element to complete a series lumped-element circuit given in Figure 1. For more on sealed enclosure design, see the Sealed Box Subwoofer Design page.

Figure 1. Sealed enclosure acoustic circuit.

In the case of a bass-reflex enclosure, a port is added to the construction. Typically, the port is cylindrical and is flanged on the end pointing outside the enclosure. In a bass-reflex enclosure, the amount of acoustic material used is usually much less than in the sealed enclosure case, often none at all. This allows air to flow freely through the port. Instead, the larger losses come from the air leakage in the enclosure. With this setup, a lumped-element acoustical circuit has the following form.

In this figure, represents the radiation impedance of the outside environment on the loudspeaker diaphragm. The loading on the rear of the diaphragm has changed when compared to the sealed enclosure case. If one visualizes the movement of air within the enclosure, some of the air is compressed and rarified by the compliance of the enclosure, some leaks out of the enclosure, and some flows out of the port. This explains the parallel combination of , , and . A truly realistic model would incorporate a radiation impedance of the port in series with , but for now it is ignored. Finally, , the acoustical mass of the enclosure, is included as discussed in the sealed enclosure case. The formulas which calculate the enclosure parameters are listed in Appendix B.

It is important to note the parallel combination of and . This forms a Helmholtz resonator (click here for more information). Physically, the port functions as the “neck” of the resonator and the enclosure functions as the “cavity.” In this case, the resonator is driven from the piston directly on the cavity instead of the typical Helmholtz case where it is driven at the “neck.” However, the same resonant behavior still occurs at the enclosure resonance frequency, . At this frequency, the impedance seen by the loudspeaker diaphragm is large (see Figure 3 below). Thus, the load on the loudspeaker reduces the velocity flowing through its mechanical parameters, causing an anti-resonance condition where the displacement of the diaphragm is a minimum. Instead, the majority of the volume velocity is actually emitted by the port itself instead of the loudspeaker. When this impedance is reflected to the electrical circuit, it is proportional to , thus a minimum in the impedance seen by the voice coil is small. Figure 3 shows a plot of the impedance seen at the terminals of the loudspeaker. In this example, was found to be about 40 Hz, which corresponds to the null in the voice-coil impedance.

Figure 3. Impedances seen by the loudspeaker diaphragm and voice coil.

Quantitative Analysis of Port on Enclosure

The performance of the loudspeaker is first measured by its velocity response, which can be found directly from the equivalent circuit of the system. As the goal of most loudspeaker designs is to improve the bass response (leaving high-frequency production to a tweeter), low frequency approximations will be made as much as possible to simplify the analysis. First, the inductance of the voice coil, , can be ignored as long as . In a typical loudspeaker, is of the order of 1 mH, while is typically 8, thus an upper frequency limit is approximately 1 kHz for this approximation, which is certainly high enough for the frequency range of interest.

Another approximation involves the radiation impedance, . It can be shown [1] that this value is given by the following equation (in acoustical ohms):

Where and are types of Bessel functions. For small values of ka,

| and |

Hence, the low-frequency impedance on the loudspeaker is represented with an acoustic mass [1]. For a simple analysis, , , , and (the transducer parameters, or Thiele-Small parameters) are converted to their acoustical equivalents. All conversions for all parameters are given in Appendix A. Then, the series masses, , , and , are lumped together to create . This new circuit is shown below.

Unlike sealed enclosure analysis, there are multiple sources of volume velocity that radiate to the outside environment. Hence, the diaphragm volume velocity, , is not analyzed but rather . This essentially draws a “bubble” around the enclosure and treats the system as a source with volume velocity . This “lumped” approach will only be valid for low frequencies, but previous approximations have already limited the analysis to such frequencies anyway. It can be seen from the circuit that the volume velocity flowing into the enclosure, , compresses the air inside the enclosure. Thus, the circuit model of Figure 3 is valid and the relationship relating input voltage, to may be computed.

In order to make the equations easier to understand, several parameters are combined to form other parameter names. First, and , the enclosure and loudspeaker resonance frequencies, respectively, are:

Based on the nature of the derivation, it is convenient to define the parameters and h, the Helmholtz tuning ratio:

A parameter known as the compliance ratio or volume ratio, , is given by:

Other parameters are combined to form what are known as quality factors:

This notation allows for a simpler expression for the resulting transfer function [1]:

where

Development of Low-Frequency Pressure Response

It can be shown [2] that for , a loudspeaker behaves as a spherical source. Here, a represents the radius of the loudspeaker. For a 15” diameter loudspeaker in air, this low frequency limit is about 150 Hz. For smaller loudspeakers, this limit increases. This limit dominates the limit which ignores , and is consistent with the limit that models by .

Within this limit, the loudspeaker emits a volume velocity , as determined in the previous section. For a simple spherical source with volume velocity , the far-field pressure is given by [1]:

It is possible to simply let for this analysis without loss of generality because distance is only a function of the surroundings, not the loudspeaker. Also, because the transfer function magnitude is of primary interest, the exponential term, which has a unity magnitude, is omitted. Hence, the pressure response of the system is given by [1]:

Where . In the following sections, design methods will focus on rather than , which is given by:

This also implicitly ignores the constants in front of since they simply scale the response and do not affect the shape of the frequency response curve.

Alignments

A popular way to determine the ideal parameters has been through the use of alignments. The concept of alignments is based upon well investigated electrical filter theory. Filter development is a method of selecting the poles (and possibly zeros) of a transfer function to meet a particular design criterion. The criteria are the desired properties of a magnitude-squared transfer function, which in this case is . From any of the design criteria, the poles (and possibly zeros) of are found, which can then be used to calculate the numerator and denominator. This is the “optimal” transfer function, which has coefficients that are matched to the parameters of to compute the appropriate values that will yield a design that meets the criteria.

There are many different types of filter designs, each which have trade-offs associated with them. However, this design approach is limited because of the structure of . In particular, it has the structure of a fourth-order high-pass filter with all zeros at s = 0. Therefore, only those filter design methods which produce a low-pass filter with only poles will be acceptable methods to use. From the traditional set of algorithms, only Butterworth and Chebyshev low-pass filters have only poles. In addition, another type of filter called a quasi-Butterworth filter can also be used, which has similar properties to a Butterworth filter. These three algorithms are fairly simple, thus they are the most popular. When these low-pass filters are converted to high-pass filters, the transformation produces in the numerator.

More details regarding filter theory and these relationships can be found in numerous resources, including [5].

Butterworth Alignment

The Butterworth algorithm is designed to have a maximally flat pass band. Since the slope of a function corresponds to its derivatives, a flat function will have derivatives equal to zero. Since as flat of a pass band as possible is optimal, the ideal function will have as many derivatives equal to zero as possible at s = 0. Of course, if all derivatives were equal to zero, then the function would be a constant, which performs no filtering.

Often, it is better to examine what is called the loss function. Loss is the reciprocal of gain, thus

The loss function can be used to achieve the desired properties, then the desired gain function is recovered from the loss function.

Now, applying the desired Butterworth property of maximal pass-band flatness, the loss function is simply a polynomial with derivatives equal to zero at s = 0. At the same time, the original polynomial must be of degree eight (yielding a fourth-order function). However, derivatives one through seven can be equal to zero if [3]

With the high-pass transformation ,

It is convenient to define , since or -3 dB. This definition allows the matching of coefficients for the describing the loudspeaker response when . From this matching, the following design equations are obtained [1]:

Quasi-Butterworth Alignment

The quasi-Butterworth alignments do not have as well-defined of an algorithm when compared to the Butterworth alignment. The name “quasi-Butterworth” comes from the fact that the transfer functions for these responses appear similar to the Butterworth ones, with (in general) the addition of terms in the denominator. This will be illustrated below. While there are many types of quasi-Butterworth alignments, the simplest and most popular is the 3rd order alignment (QB3). The comparison of the QB3 magnitude-squared response against the 4th order Butterworth is shown below.

Notice that the case is the Butterworth alignment. The reason that this QB alignment is called 3rd order is due to the fact that as B increases, the slope approaches 3 dec/dec instead of 4 dec/dec, as in 4th order Butterworth. This phenomenon can be seen in Figure 5.

Equating the system response with , the equations guiding the design can be found [1]:

Chebyshev Alignment

The Chebyshev algorithm is an alternative to the Butterworth algorithm. For the Chebyshev response, the maximally-flat passband restriction is abandoned. Now, a ripple, or fluctuation is allowed in the pass band. This allows a steeper transition or roll-off to occur. In this type of application, the low-frequency response of the loudspeaker can be extended beyond what can be achieved by Butterworth-type filters. An example plot of a Chebyshev high-pass response with 0.5 dB of ripple against a Butterworth high-pass response for the same is shown below.

The Chebyshev response is defined by [4]:

is called the Chebyshev polynomial and is defined by [4]:

Fortunately, Chebyshev polynomials satisfy a simple recursion formula [4]:

For more information on Chebyshev polynomials, see the Wolfram Mathworld: Chebyshev Polynomials page.

When applying the high-pass transformation to the 4th order form of , the desired response has the form [1]:

The parameter determines the ripple. In particular, the magnitude of the ripple is dB and can be chosen by the designer, similar to B in the quasi-Butterworth case. Using the recursion formula for ,

Applying this equation to [1],

Thus, the design equations become [1]:

Choosing the Correct Alignment

With all the equations that have already been presented, the question naturally arises, “Which one should I choose?” Notice that the coefficients , , and are not simply related to the parameters of the system response. Certain combinations of parameters may indeed invalidate one or more of the alignments because they cannot realize the necessary coefficients. With this in mind, general guidelines have been developed to guide the selection of the appropriate alignment. This is very useful if one is designing an enclosure to suit a particular transducer that cannot be changed.

The general guideline for the Butterworth alignment focuses on and . Since the three coefficients , , and are a function of , , h, and , fixing one of these parameters yields three equations that uniquely determine the other three. In the case where a particular transducer is already given, is essentially fixed. If the desired parameters of the enclosure are already known, then is a better starting point.

In the case that the rigid requirements of the Butterworth alignment cannot be satisfied, the quasi-Butterworth alignment is often applied when is not large enough.. The addition of another parameter, B, allows more flexibility in the design.

For values that are too large for the Butterworth alignment, the Chebyshev alignment is typically chosen. However, the steep transition of the Chebyshev alignment may also be utilized to attempt to extend the bass response of the loudspeaker in the case where the transducer properties can be changed.

In addition to these three popular alignments, research continues in the area of developing new algorithms that can manipulate the low-frequency response of the bass-reflex enclosure. For example, a 5th order quasi-Butterworth alignment has been developed [6]; its advantages include improved low frequency extension, and much reduced driver excursion at low frequencies and typically bi-amping or tri-amping, while its disadvatages include somewhat difficult mathematics and electronic complication (electronic crossovers are typically required). Another example [7] applies root-locus techniques to achieve results. In the modern age of high-powered computing, other researchers have focused their efforts in creating computerized optimization algorithms that can be modified to achieve a flatter response with sharp roll-off or introduce quasi-ripples which provide a boost in sub-bass frequencies [8].

References

[1] Leach, W. Marshall, Jr. Introduction to Electroacoustics and Audio Amplifier Design. 2nd ed. Kendall/Hunt, Dubuque, IA. 2001.

[2] Beranek, L. L. Acoustics. 2nd ed. Acoustical Society of America, Woodbridge, NY. 1993.

[3] DeCarlo, Raymond A. “The Butterworth Approximation.” Notes from ECE 445. Purdue University. 2004.

[4] DeCarlo, Raymond A. “The Chebyshev Approximation.” Notes from ECE 445. Purdue University. 2004.

[5] VanValkenburg, M. E. Analog Filter Design. Holt, Rinehart and Winston, Inc. Chicago, IL. 1982.

[6] Kreutz, Joseph and Panzer, Joerg. "Derivation of the Quasi-Butterworth 5 Alignments." Journal of the Audio Engineering Society. Vol. 42, No. 5, May 1994.

[7] Rutt, Thomas E. "Root-Locus Technique for Vented-Box Loudspeaker Design." Journal of the Audio Engineering Society. Vol. 33, No. 9, September 1985.

[8] Simeonov, Lubomir B. and Shopova-Simeonova, Elena. "Passive-Radiator Loudspeaker System Design Software Including Optimization Algorithm." Journal of the Audio Engineering Society. Vol. 47, No. 4, April 1999.

Appendix A: Equivalent Circuit Parameters

| Name | Electrical Equivalent | Mechanical Equivalent | Acoustical Equivalent |

|---|---|---|---|

| Voice-Coil Resistance | |||

| Driver (Speaker) Mass | See | ||

| Driver (Speaker) Suspension Compliance | |||

| Driver (Speaker) Suspension Resistance | |||

| Enclosure Compliance | |||

| Enclosure Air-Leak Losses | |||

| Acoustic Mass of Port | |||

| Enclosure Mass Load | See | See | |

| Low-Frequency Radiation Mass Load | See | See | |

| Combination Mass Load |

Appendix B: Enclosure Parameter Formulas

Based on these dimensions [1],

| (inside enclosure gross volume) | (baffle area of the side the speaker is mounted on) |

| specific heat of air at constant isovolumetric process (about at 300 K) | specific heat of filling at constant volume () |

| mean density of air (about at 300 K) | density of filling |

| ratio of specific heats (Isobaric/Isovolumetric processes) for air (about 1.4 at 300 K) | speed of sound in air (about 344 m/s) |

| = effective density of enclosure. If little or no filling (acceptable assumption in a bass-reflex system but not for sealed enclosures), | |

New Acoustic Filter For Ultrasonics Media

Introduction

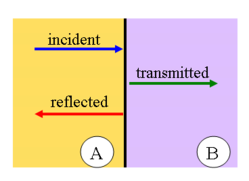

Acoustic filters are used in many devices such as mufflers, noise control materials (absorptive and reactive), and loudspeaker systems to name a few. Although the waves in simple (single-medium) acoustic filters usually travel in gases such as air and carbon-monoxide (in the case of automobile mufflers) or in materials such as fiberglass, polyvinylidene fluoride (PVDF) film, or polyethylene (Saran Wrap), there are also filters that couple two or three distinct media together to achieve a desired acoustic response. General information about basic acoustic filter design can be perused at the following wikibook page Acoustic Filter Design & Implementation. The focus of this article will be on acoustic filters that use multilayer air/polymer film-coupled media as its acoustic medium for sound waves to propagate through; concluding with an example of how these filters can be used to detect and extrapolate audio frequency information in high-frequency "carrier" waves that carry an audio signal. However, before getting into these specific type of acoustic filters, we need to briefly discuss how sound waves interact with the medium(media) in which it travels and how these factors can play a role when designing acoustic filters.

Changes in Media Properties Due to Sound Wave Characteristics

= (equilibrium) density of medium = speed of sound in medium

is interpreted as the (time-averaged) rate of energy transmission of a sound wave through a unit area normal to the direction of propagation, and this parameter is also an important factor in acoustic filter design because the characteristic properties of the given medium can change relative to intensity of the sound wave traveling through it. In other words, the reaction of the particles (atoms or molecules) that make up the medium will respond differently when the intensity of the sound wave is very high or very small relative to the size of the control area (i.e. dimensions of the filter, in this case). Other properties such as the elasticity and mean propagation velocity (of a sound wave) can change in the acoustic medium as well, but focusing on frequency, impedance, and/or intensity in the design process usually takes care of these other parameters because most of them will inevitably be dependent on the aforementioned properties of the medium.

Why Coupled Acoustic Media in Acoustic Filters?

In acoustic transducers, media coupling is employed in acoustic transducers to either increase or decrease the impedance of the transducer, and, thus, control the intensity and speed of the signal acting on the transducer while converting the incident wave, or initial excitation sound wave, from one form of energy to another (e.g. converting acoustic energy to electrical energy). Specifically, the impedance of the transducer is augmented by inserting a solid structure (not necessarily rigid) between the transducer and the initial propagation medium (e.g. air). The reflective properties of the inserted medium is exploited to either increase or decrease the intensity and propagation speed of the incident sound wave. It is the ability to alter, and to some extent, control, the impedance of a propagation medium by (periodically) inserting (a) solid structure(s) such as thin, flexible films in the original medium (air) and its ability to concomitantly alter the frequency response of the original medium that makes use of multilayer media in acoustic filters attractive. The reflection factor and transmission factor and , respectively, between two media, expressed as...