Kitchen Remodel/Cabinet front styles

|

Cabinet front styles

[edit | edit source]My choices

[edit | edit source]Because my kitchen includes three distinctly set apart spaces, I chose differently looking front elements:

-

Gray ones for the actual kitchen…

-

…white ones for the pantry…

-

…and oak veneer for the cabinets that face the dining area.

-

Alas, too expensive for us: walnut veneer fronts from SemiHandmade; notice the continuous wood grain

The gray I chose because it would go well with the reddish brown tones (shelves, flooring) that I had in mind combining it with and because it would bring the white of the countertop out. I was planning on two waterfalls which were supposed to get all the attention. Another reason for this selection was that those gray fronts came with integrated handles (routed grooves), which I liked a lot, not just for the looks, but also because the absence of protruding handles allowed us an even more efficient use of the available space (smaller fillers!). The product name is Voxtorp.

The white, also Voxtorp, was a no-brainer because the pantry is a very narrow space, and the snow white fronts would make it feel both clean and a little less cramped.

For the dining space, we had originally planned to splurge and to purchase an Ikea-hack from SemiHandmade. They offered a product that we found extremely cool: custom arrays of cabinet fronts that share one large sheet of walnut veneer. So the elements look as if the were cut out of one huge piece of wood. Unfortunately, we had run out of money and chose the next best thing that we could still afford, which was Ikea's Sinarp (oak veneer). It turned out to be an excellent choice because it very much matches the shade of our dining room table and chairs.

Little theory of cabinet fronts

[edit | edit source]Materials

[edit | edit source]The most common material for cabinet fronts are high density fiber board and "solid hardwood", either coated with thermofoil or melamine, or painted or veneered. Typical specific woods are maple, cherry, oak, red oak, alder, hickory, walnut, birch, poplar, and mahogany.

Types

[edit | edit source]

The traditional type of a cabinet front element in the United States is the panel door (see image: C), made out of four solid wood frame pieces which enclose a (thinner) panel. Slab doors are made out of one solid piece of wood or engineered wood (A) and commonly associated with a more modern appearance. Some doors, for example plank style doors, fit into neither of those categories.

Panel type

[edit | edit source]

The most basic panel door is the Shaker door, which is defined by a cope+stick construction…

-

A Shaker style door

-

Anatomy of a cope+stick panel door (A = stile, B = rail, C = panel)

-

Anatomy of a mitered panel door

-

A mitered panel door

…and a complete absence of decorative elements; the panel is flat and recessed and there is absolutely no moulding, neither on the panel nor on the frame.

Due to their minimalism, Shaker doors pass for all-rounders that suit both a modern and a traditional kitchen. This is certainly a matter of taste and therefore not disputable, but as the famous German filmmaker Alexander Kluge once said: "In Danger and Deep Distress, the Middleway Spells Certain Death".

However, in my opinion, the cool thing about panel doors is that virtually every seemingly inconsequential part of those can be subject to adornment or variation:

-

The "lip" (= outer edge of the frame)

-

The "bead" (= inner edge of the frame) can be cut…

-

…or complemented with additional moulding

-

The "raise" (= edge of the panel)

-

The shape of the upper rail (or both rails)

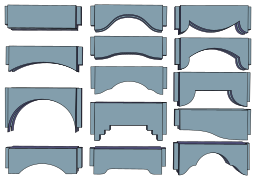

Consequently, there is an immense range of different designs in panel doors, even within the assortments of mainstream manufacturers:

Some manufacturers also differentiate between "one pass", "two pass", "three pass" etc. Those numbers refer to the number of passes that a router needs to take to produce a specific moulding profile.

Although I have a strong personal preference for the modern style and therefore naturally gravitate towards slab doors, I am in awe of cabinet artists. They know exactly where to position an ogee moulding and where not or when it should be accompanied by a cove or a bead or just a little step or a chamfer. They also know what is historically accurate and what is not. This is an amazing set of skills.

Slab type

[edit | edit source]Slab doors come with laminate, thermofoil, melamine, lacque, high-gloss, veneer, paint-grade, stain-grade or metal surfaces among others. The surface can be smooth, textured or grooved; it can even show moulding. Some slab doors imitate the appearance of a panel door. But apart from such attempts to mock a traditional door, hinted frames on slab doors tend to be much narrower than on panel doors.

-

On the first glance, some slab doors may look like panel doors.

-

Slab doors from mainstream brands…

-

…like KraftMaid, Woodmark or Hampton Bay…

-

…can be a rather dull thing.

-

For those manufacturers, it is only a niche product.

-

Manufacturers of frameless cabinets offer more variety, for example front elements with integrated handles.

Overlays

[edit | edit source]Another important parameter in cabinet front elements is overlay. Overlay is the width and height of a drawer front or cabinet door in relation to aperture's and the cabinet frame's dimensions:

- Inset

- The front elements (drawer fronts, doors) fill the aperture. This used to be standard in the U. S., historically, but later became the most uncommon type. One U. S. based manufacturer who still offers it is Maplevilles Cabinetry in California.

- Standard, or partial overlay

- The front elements are larger than the aperture, but considerably narrower than the cabinet frame.

- Full

- The front elements are even larger. Different manufacturers make different use of this term. Some mean that the overlay is a bit larger than "Standard" with still a noticeable gap; others mean that the face frame is entirely covered.

- Frameless

- Modern frameless cabinets tend very much to have overlays that virtually fill the entire front; there is only minuscule gaps left for unobstructed operation.

-

Common overlays: A.+B. "full", C. Standard/partial, D. inset, E. frameless

-

Inset drawers and doors in a custom built kitchen

-

Framed cabinets with only little overlay

-

Framed cabinets with only little overlay

-

Framed cabinets with very large overlay

-

Frameless cabinets

Handles

[edit | edit source]

Crucial for the overall appearance of a cabinet front is also the choice of handles. There are multiple types:

- If a push opener is installed, a drawer or door won't need any handle at all. This won't work for high-gloss front elements because even after only a day there would be fingerprints all over.

- Some manufacturers offer drawer fronts and doors with an integrated grooved finger pull at the element's lip.

- An alternative is a simple cut-out.

- A more elaborate solution is a recess handle. That is an element that is flush-mounted into the door.

- One of the advantages of a pull-handle is that it is non-committal: if you later decide that you rather want to have conventional handles, the element's face will still be pristine with no drill holes. Pull-handles are typically screwed to the element's backside.

- The vast majority of conventional handles require two drill holes. Their greatest advantage is a virtually endless variety.

- An alternative is a handle that requires only one drill hole. This is something highly committal since that centered drill hole is something you will be stuck with if you later decide to replace the handle.

Ikea-hacks

[edit | edit source]

If money is not a problem, any IKEA kitchen can be completed with front elements from a different manufacturer. There is a considerable number of companies worldwide who are specialized in "Ikea-hacks": products that are made to modify or to complete Ikea products. In the U. S. for example, there are, among others:

- Semihandmade, small selection of innovative designs

- Dunsmuir, their specialty is integrated pulls

- Kokeena, large selection of veneer and textured laminate

- Scherr's, specialist in custom-made front elements

- The Cabinet Face, large selection of colors and styles

- Ricabi, specialist in framed front elements

- Nieu Cabinet Doors, Shaker-style and some innovative designs

- Walnut x Oak, small selection of veneered elements