Infrastructure Past, Present, and Future Casebook/Printable version

| This is the print version of Infrastructure Past, Present, and Future Casebook You won't see this message or any elements not part of the book's content when you print or preview this page. |

The current, editable version of this book is available in Wikibooks, the open-content textbooks collection, at

https://en.wikibooks.org/wiki/Infrastructure_Past,_Present,_and_Future_Casebook

JFK Terminal One

Introduction

[edit | edit source]This casebook is a case study on The New Terminal One at JFK International Airport developed by Matthew Bond, Aaron Taylor, and Honestie Kern as part of the Infrastructure Past, Present and Future: GOVT 490/CEIE 499 Fall 2024 course at George Mason University's Schar School of Policy and Government and the Volgenau School of Engineering, and Sid and Reva Dewberry Department of Civil, Environmental, and Infrastructure Engineering. Under the instruction of Professor Jonathan Gifford.

Summary

[edit | edit source]

John F. Kennedy International Airport's New Terminal One is part of a 19.5-billion-dollar redevelopment and renovation project of the JFK International Airport through a public-private partnership focused on revitalizing and enlarging JFK Airport's capacity to accommodate 21st-century aircraft and increased travel demand. John F Kennedy International Airport (JFK) is located in New York City, New York within the Queens borough (Lat/Long: N 40.6399281, W 73.7787922)[1]. The financers in partnership with the Port Authority of New York and New Jersey comprised of Ferrovial, JLC infrastructure, Ullico, and the Carlyle Group are overseeing the development of the complex which will consist of around 2.5 to 3 million square feet of space which will replace the existing terminals 1 and 2 as well as the previously demolished in 2013 terminal 3.[2] The New Terminal One will have 23 gates all of which will be international serving approximately 30 to 40 airline partners of the JFK airport.[3] The terminal will feature art from local New York City artists with an emphasis on integrating local culture into the feel of the airport.

Timeline

[edit | edit source]1948 - JFK International Airport opens as “New York International Airport”

1963 - JFK International Airport is given the official name “JFK International Airport”[4]

1998 - Terminal 1 opens serving 11 gates

October 2018- Former New York Governor Andrew Cuomo announces the plans improve passenger services at the JFK Airport.[5]

July 2019 - The port authority of New York and New Jersey formally approves the project plans for the new JFK Terminal One

September 8, 2022 - Construction begins on new JFK Terminal One.

September 8, 2022 - Dr. Gerrard Bushell assumes role of CEO over the New JFK Terminal One

April 1, 2024 - Jennifer Aument assumes the role of CEO of the New JFK Terminal One[6]

July 2024- 2.5 billion in green bonds were issued to the project

June 2026 - First 14 gates of the New Terminal One are set to open[7]

2030 - The New JFK Terminal One is set to be fully opened[7]

Actors

[edit | edit source]Gina Bigler, P.E. - Head of Construction for JFK Terminal One under the Port Authority

Jennifer Aument - As of April 1, 2024 CEO of New Terminal One[6]

The Carlyle Group - a global investment firm that is focused on a range of investments including infrastructure financially sponsoring the New JFK terminal one project

Ullico - an insurance company based in the United States focused on providing insurance to union families financially sponsoring the New JFK terminal one project

JLC Infrastructure - An asset management firm financially sponsoring the New JFK terminal one project

Port Authority of New York and New Jersey - A governmental body with the authority over the JFK airport and surrounding New York city transportation.[8]

AECOM Tishman - The Construction Manager (CM) that will be constructing New Terminal One

Gensler - The leading global design and architecture firm for JFK Terminal One

Funding and Financing

[edit | edit source]The construction of the New JFK International Airport is being done through a public-private partnership or P3 project with its private sponsors (Ferrovial, Ullico, JLC, and the Caryle Group) in conjunction with the Port Authority of New York and New Jersey. Ferrovial is a Spain-based company[9] focused on the investment and management for the new JFK terminal one project additionally according to the JFK terminal one CEO Jennifer Aument some of their investment will be going towards the pensions of the labor unions involved in the project[3]. JLC is an asset management firm and according to Jennifer Aument they are “Experts on deploying minority capital.[3]” Ullico is a insurance company based in the United States that focuses on providing insurance to union families. The Carlyle Group is a global investment firm that is focused on a range of investments including infrastructure.[2]

The Design build was originally financed through equity and debt of around 8.4 billion dollars. In July 2024 2.5 billion in green bonds were issued to the project which makes this project the recipient of the single largest bond issuance in the aviation industry[10]. These bonds were funded by the series 2024 bonds and the New York Transit Development cooperation acted as the conduit of these bonds.

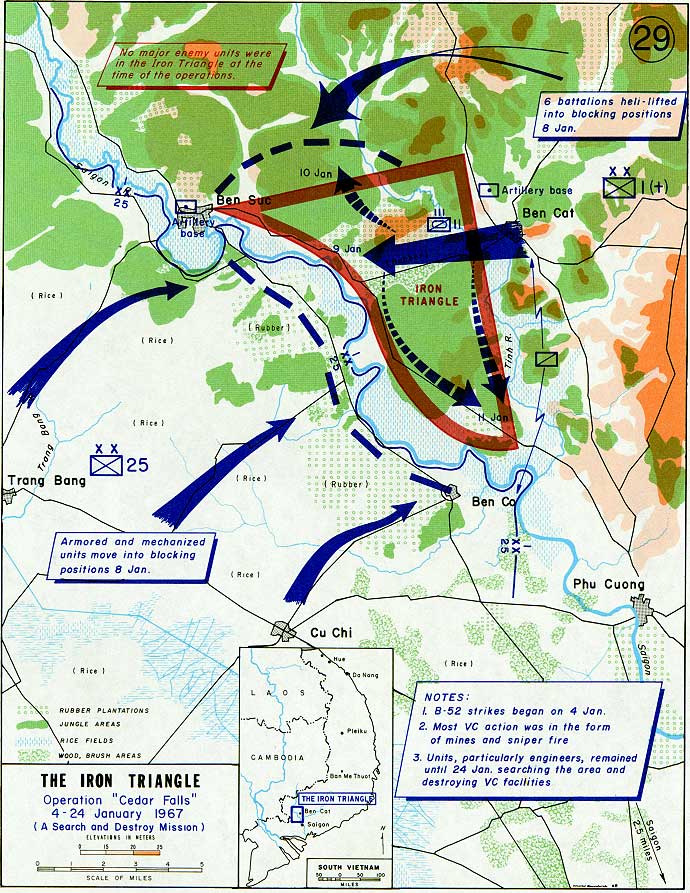

Map of Location

[edit | edit source]

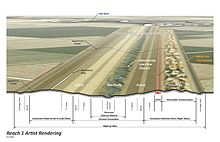

Institutional Arrangements

[edit | edit source]In 2019, JFK was the sixth busiest airport in the United States and the twentieth busiest in the world. JFK Terminal One is going to be operating one of four terminal complexes when it opens in 2026. In 2019, the existing Terminal One served 13% of the entire airport’s passenger traffic. [11]The prediction is to have an annual growth rate of 3.3% annually with tourism alone increasing the growth. In 2022, for the Regional Growth Rate, there were 60 million enplanements which is -8% as initial predictions prior to the COVID-19 pandemic. This figure has been increasingly recovering. The International Growth Rate had 17 million enplanements in 2022, at a rate of -23% attributed to the pandemic recovery. These figures are forecasted to only rise further and recover to a rate of 96% of the pre-pandemic rates by 2025. The future of Terminal One will increase capacity with 14 wide body gates and 5 live hardstands by 2028. The wide body gates are going to help with providing the airlines with peak-time flexibility. This is especially important for international flights. The live hardstands are going to assist with providing a space for the airplanes to park while in between flights. JFK Airport is expecting to service 100 million passengers by 2050. Terminal One will be installing biometric infrastructure to make boarding and deplaning a faster and smoother transition for passengers. A part of the $19 billion dollar investment will include 150% larger concessions that will provide duty free goods unlike any other United States International terminal. The New Terminal One will be a test case for privately operated terminals across the United States. As of recent years, there has been a large push overturning the control of airports over to Port Authorities. JFK is still operated by the Port Authority of New York and New Jersey.

Infrastructure Improvements

[edit | edit source]To handle the increased traffic of the New Terminal One, additional improvements are also being made to the existing infrastructure of JFK and its surrounding areas as part of the project. The JFK AirTrain, already accountable for 27,000 trips daily as of 2024[12], is expected to see an increase in capacity and frequency[13]. The elevated rail system connects the terminals of the airport and the airport to surrounding neighborhoods and the MTA system. Within the airport, the current tangled mess of roads and parking lots are expected to see a complete overhaul[13]. The roads will be reworked into a streamlined system of ring roads, with a north loop and a south loop. The parking lots, currently dotted around where space is available between the current roads, will be relocated to fit centrally within the rings. Outside of the airport, additional lanes in both directions are being added to the Van Wyck Expressway, connecting the airport to the neighborhoods to its north[13].

Narrative of the Case

[edit | edit source]A common theme found throughout the various press releases and media spots on the development of the new terminal is the perception that JFK is one of, if not the most crucial gateway into the United States. New York City is a city well known for its reputation as one of the first places visitors to the United States experience, with Ellis Island being one of the nation’s most prolific immigration stations. Even after the shuttering of the immigration station at Ellis Island, the city has remained one of the most common points of entry for immigrants arriving from overseas (excluding land crossings). JFK airport has effectively supplanted Ellis Island as the most popular point of entry for international travelers into the United States. In 2023, JFK was the busiest airport in the United States by international traffic, topping the Department of Transportation’s “Passenger Gateways to the World” list, with almost 10 million more international arrivals than LAX, the second airport on the list[14].

The perception of New York City, and by extension JFK, as a welcoming face representing New York City and the greater United States is evident in the words of governors, congresspeople, state legislators, and industry leaders. Both governors Cuomo and Hochul have referred to JFK as a “global gateway.”[15][16] This sentiment is further reinforced by the fact that the terminal will be dedicated entirely to international carriers, particularly Air France, Etihad, KLM, Korean Air, LOT Polish Airlines, EVA Airways, and Air Serbia.

Policy and Policy Issues

[edit | edit source]Public-Private Partnership

Central to the New Terminal One project (and the other improvement projects being made around JFK) is the public-private partnership arrangement between PANYNJ and the private contractors working on the project. Through the use of the public-private partnership arrangement, the upfront costs of the project are shouldered by the private sector, saving the Government of New York billions of dollars in taxpayer money. As the lessor of the new facilities, the PANYNJ will retain the rights to collecting rent and revenue sharing once the new facilities are operational. Once the first phase (the first 14 gates) come online, operational costs are expected to increase considerably. This is offset however by the rent the PANYNJ will be collecting from terminal tenants as well as revenue sharing from the ~400 million in revenues projected in 2026[17].

While the savings to the taxpayer are considerable, public-private partnerships can raise accountability and transparency questions, as the primary actors during the planning and construction phases are in the private sector.

Equity

The New Terminal one will be constructed through the use of union labor, with a commitment to local participation and workforce inclusion. The project aims to provide opportunities for local businesses, including minority- and women-owned business enterprises and service-disabled veteran-owned businesses according to the CEO Jennifer Aument.[3] Over 10,000 local jobs have been created through the construction of this project. The 2024 issuance bond to the project designated 40% of the issuance be allocated to minority and women owned business enterprises. By the Spring of 2024, according to Governor Hochul, that over 2.3 billion dollars had been invested in minority women-owned business enterprises over the course of the terminal project, a record setting amount[18].

Energy and Sustainability

Airports like JFK have faced challenges with energy demand, outages at terminals, and the consistency of power. JFK Terminal One partnered with AlphaStruxure to assist in development of a solar project that will include 13,000 solar panels making it the largest solar array in New York City.[19] This is a major policy development as it will be the largest in New York City and the largest at any airport terminal in the United States. This energy policy implementation will distribute energy from the solar panels, fuel cells, and a battery energy storage system to power the terminals everyday operations.[20] The terminal will have an integrated microgrid so that it will be operational in potential adverse circumstances all provided primarily through green forms of energy. The initiative is the airport's contribution towards the future and renewable energy.

Facilities Management

Janitorial, landscaping maintenance, pest control, and waste management services are currently being sought out to partner for facilities management. The Request for Proposal was announced in September 2024. There is a strong encouragement to partner with a firm that is diversified such as a minority or woman owned business. The RFP is due in late December 2024.[21]

Contracts

To date the airlines that are expecting to be operated out of the New Terminal One include: Air France, KLM, Etihad Airways, LOT Polish Airlines, Korean Air, EVA Airways, Air Serbia, SAS, and Air China. All of these have initiated contracts with expected usage to come in 2026. The New Terminal One is expecting to see additional airlines contract to be able to utilize the new terminal. The airlines are a single factor of the operators. There will be a vast majority of corporations that will engage in the 300,000 square feet for the dining, retail, lounges, and recreational areas. These corporations will be quick to be included in taking advantage of the newest and largest terminal to enhance their businesses as well.

Takeaways

[edit | edit source]The JFK New Terminal One will serve as a major international gateway to New York City and through its completion will have created over 10,000 jobs. Large efforts have been made towards sustainability with a large emphasis on green energy for its future functionality. With its bond issuance mandating at least 40% of contracts include minority and women-owned businesses this project was done with a strong attempt to distribute sub-contracts equitably.

Discussion Questions

[edit | edit source]How might the New JFK terminal one affect the traffic and accessibility of New York's transportation infrastructure?

What might be the implications for local neighborhoods and if it has a negative impact is that justified by the progress this project brings?

What are the benefits/downsides of Public-Private partnerships? Are they beneficial to the taxpayer and save money or are private industries getting involved where only the government should be or visa versa?

Are the 9.5 billion dollars spent on the JFK Terminal One going to pay off economically or is the cost too excessive for the benefit?

Considering the recent Covid-19 pandemic, is investing in airport infrastructure a safe bet for the future of travel?

Class readings for discussion Questions

[edit | edit source]Please read the following in Preparation for Class Discussion.

World Economic Forum - How is Covid 19 Changing airports?

State public-private partnership (P3) legislation and P3 project implementation

Impact of airport policies on regional development. Evidence from the Colombian case

Please read Chapter 2 and Chapter 9 of Private Financing of Public Transportation Infrastructure: Utilizing Public-Private Partnerships

Utilizing Public-Private partnerships

References

[edit | edit source]

South Fork Wind Farm

This page is for a case study on the South Fork Wind Farm by Jose Galeano Amaya, Jad Dannoura, and Nikolas Hawley as part of the Infrastructure Past, Present and Future: GOVT 490-003 / CEIE 499-005 Spring 2024 course at George Mason University's Schar School of Policy and Government, and the Volgenau School of Engineering, and Sid and Reva Dewberry Department of Civil, Environmental, and Infrastructure Engineering. Under the instruction of Professor Jonathan L. Gifford.

Summary

[edit | edit source]A pioneer in offshore wind farm development in the United States is the South Fork Wind Farm. It is located about 35 miles to the east of New York's Montauk Point. Eversource Energy and Ørsted collaborated to provide clean, renewable energy to Long Island. With about 12 turbines, it will produce enough electricity to run about 70,000 households. New York State's efforts to minimize greenhouse gas emissions through renewable energy and a reduced reliance on fossil fuels are further aided by the initiative. The Bureau of Ocean Energy Management (BOEM), has approved South Fork, which is also known for emphasizing preservation of the environment, sustainability, and employment creation in the community. Numerous local stakeholders, particularly those involved in environmental protection and the fishing sector, have been consulted and studied in great detail regarding its possible ecological effects.The South Fork Wind Farm now generates approximately 130 megawatts of renewable energy, sufficient to power around 70,000 homes, contributing significantly to New York's clean energy goals.

Timeline of Events

[edit | edit source]- August 18, 2011: BOEM published a "Call for Information and Nominations for Commercial Leasing for Wind Power on the OCS Offshore Rhode Island and Massachusetts" in the Federal Register so that interest in a project could be measured.[7]

- On July 31, 2013: BOEM auctioned two leases for North Lease Area (Lease OCS-A0486) and the South Lease Area (Lease OCS-A0487), that were won by Deepwater Wind.[7]

- 2017: The Long Island Power Authority (LIPA) Board of Trustees approved the South Fork Wind project, marking the beginning of its development phase.[6]

- June 29, 2018: South Fork Wind, LLC submitted its Construction and Operations Plan (COP) to the Bureau of Ocean Energy Management (BOEM) for review.[2]

- 2019: Deepwater Wind is acquired by Ørsted.[3]

- January 16, 2020: Deepwater Wind submits an application to assign 13,700 acres of OCS-A 0486 to Deepwater Wind South Fork, LLC.[7]

- March 23, 2020: BOEM approved the new assignment of the lease with a new lease number number OCS-A 0517.[7]

- November 24, 2021: The U.S. Department of the Interior’s BOEM issued the Record of Decision (ROD), completing the federal environmental review and granting approval for the project to proceed.[22]

- January 18, 2022: BOEM approved the Construction and Operations Plan for the South Fork Wind Farm and South Fork Export Cable Project, allowing construction to commence.[2]

- February 2022: Onshore construction began, starting with the installation of the underground transmission line that would connect the offshore wind farm to the Long Island electric grid.[6]

- June 2023: The project reached its "steel in the water" milestone with the installation of the first monopile foundation, marking significant progress in offshore construction.[6]

- February 2024: The final turbine was installed, completing the offshore construction phase of the wind farm.[6]

- February 13, 2024:Eversource Energy announces sale of sell their fifty-percent ownership of the South Fork Wind Farms to Global Infrastructure Partners (GIP).[13]

- March 14, 2024: Governor Kathy Hochul, alongside U.S. Secretary of the Interior Deb Haaland, announced the completion of the South Fork Wind project. All 12 turbines were constructed and the wind farm began delivering power to Long Island and the Rockaways, marking it as America's first utility-scale offshore wind farm.[6]

List of Actors

[edit | edit source]Developers & Partners:

[edit | edit source]Deepwater Wind: A predecessor to Ørsted in the development of the South Fork Wind Farm.

Ørsted: A global leader in renewable energy, Ørsted co-developed the South Fork Wind Farm.

Eversource Energy: A New England-based energy company that partnered with Ørsted in the development of the wind farm.

Global Infrastructure Partners (GIP): An infrastructure investor that purchased the stake that Eversource Energy had in South Fork Wind Farm. [13]

Key individuals:

[edit | edit source]Governor Kathy Hochul: The Governor of New York, who announced the completion of the South Fork Wind project and emphasized its significance in advancing the state's clean energy goals.

Secretary Deb Haaland - The U.S. Secretary of the Interior, who participated in the announcement of the project's completion, highlighting its role in the nation's renewable energy efforts.

Stakeholders:

[edit | edit source]Long Island Power Authority (LIPA): The utility company serving Long Island, which approved the project and will distribute the generated electricity to local consumers.[23]

Government agencies:

[edit | edit source]Bureau of Ocean Energy Management (BOEM): A division of the U.S. Department of the Interior responsible for managing offshore energy resources. BOEM approved the Construction and Operations Plan for the South Fork Wind Farm.

United States Department of the Interior: An executive department of the U.S. federal government that is in charge of the nation's natural resources and cultural heritage.[24]

Map of the Location

[edit | edit source]Funding and Financing

[edit | edit source]The construction of the South Fork Wind Farm project was funded through a private joint venture between Ørsted and Eversource Energy; originally the ownership of the South Fork Wind Farm was divided fifty-fifty between Ørsted and Eversource Energy.[25] On February 13, 2024, Eversource Energy announced the execution of a definitive agreement to sell their fifty-percent ownership of the South Fork Wind Farms to Global Infrastructure Partners (GIP).[13] The South Fork Wind Farm also received a Power Purchase Agreement (PPA) from the Long Island Power Authority, for the original 90 megawatts project, which was later updated to include an additional 40 megawatts.[23]

Institutional Arrangement

[edit | edit source]The Outer Continental Shelf Lands Act (OCSLA) defines outer continental shelves (OCS) as all submerged lands lying 3 miles offshore and requires the Secretary of the Interior to be responsible for their development.[26] The United States Department of the Interior through its Bureau of Ocean Energy Management (BOEM) provides development of the OCS through leases that are awarded to renewable energy projects. On August 18, 2011, the BOEM published a "Call for Information and Nominations for Commercial Leasing for Wind Power on the OCS Offshore Rhode Island and Massachusetts" to measure interest in the development of the area and received eight commercial indications of interest; which included Deepwater Wind, the company that would ultimately win the leased area.[7] Deepwater Wind would be bought by Ørsted in 2019 through an agreement with the D.E. Shaw Group for a purchase price of 510 million USD; which provided the offshore wind development project to Ørsted, that project would become the South Fork Wind Farm.[3] On January 18, 2022, the BOEM would approve the construction, and operations plan of South Fork Wind Farm; construction would begin that same month and end in March 2024.[2][27]

Narrative of the Case

[edit | edit source]A growing demand for renewable energy production in the United States highlights a shift in the consumption of energy and the future of energy production in America. At the federal level, the U.S. Department of the Interior has joined a government-wide commitment to deploy 30 gigawatts (30000 megawatts) of offshore wind by 2030; which can be aided by the Bureau of Ocean Energy Management.[28] At the state level, New York is hoping to achieve 9,000 megawatts of wind energy by 2035; as a way to transition into a zero-emission electric grid.[29] The South Fork Wind Farm as infrastructure assists the achievement of these goals, as an offshore wind farm that provides 130 megawatts of energy to areas in New York. Its construction as a private joint venture demonstrates the role of corporations in the creation and maintenance of infrastructure in the U.S. The corporations in this case provided their expertise in the creation of the South Fork Wind Farm, Ørsted as a leader in offshore wind power having 30 years of experience, operating and developing projects that account for approximately 2,800 megawatts of offshore wind energy and investing 20 billion USD in offshore projects in America.[30] The change of ownership also demonstrates another feature of corporations working on infrastructure, that actors can sell their stake to other corporations; Eversource Energy selling its stake to GIP.

Policy Issues

[edit | edit source]Bureaucratic Process: The process of obtaining the lease to an area and the necessary procedures that are required before the lease is able to be built upon, can impede a project and decrease the efficiency of it. As the timeline shows, the process of obtaining the approval to start construction of a project can take a lot of time.

Environmental Impact: Building in outer continental shelves can harm the area, which makes the bureaucratic process a necessity to avoid the destruction of habitats in the area. This act of balancing environmental protections and construction of important infrastructure is one that heavily depends on the government.

Private Corporations: The South Fork Wind Farm demonstrates that private corporations can take all the risk in the construction and maintenance of infrastructure. Yet, this creates a variety of issues such as those of ownership, accountability, and sustainability.

Takeaways

[edit | edit source]The amount of bureaucracy that is present in the planning and construction of infrastructure in federal land, demonstrates the importance of the executive branch and demonstrates that a balance is needed between bureaucratic processes and the construction of infrastructure.

Discussion Questions

[edit | edit source]Does the environmental and economical benefit of the South Fork Wind Farm outweigh the potential ecological impacts and concerns raised by local communities and industries such as commercial fishing?

Is the investment in offshore wind farms, like the South Fork Wind Farm, a better use of funds than investing in other renewable energy sources such as solar or onshore wind?

What can the United States learn from other nations that are familiar with the creation and maintenance of offshore wind farms and can the current bureaucratic process be accelerated?

Additional Readings

[edit | edit source]Environmental licensing for offshore wind farms: Guidelines and policy implications for new markets

Licensing for offshore wind farms

Levelized Costs of New Generation Resources in the Annual Energy

Costs of new generation resources

United States Environmental Protection Agency South Fork Wind LLC Fact Sheet

EPA Fact Sheet (section 3 and 4)

References

[edit | edit source]Hambantota Port, Sri Lanka

Introduction

[edit | edit source]This casebook is a case study on the Hambantota International Port by Anthony Reyes and Peter DerHagopian as part of the Infrastructure Past, Present and Future: GOVT 490/CEIE 499 Fall 2024 course at George Mason University's Schar School of Policy and Government and the Volgenau School of Engineering, and Sid and Reva Dewberry Department of Civil, Environmental, and Infrastructure Engineering. Under the instruction of Professor Jonathan Gifford.

Summary

[edit | edit source]Hambantota International Port, also known as Magampura Mahinda Rajapaksa Port, is a deep water port located in Hambantota, Sri Lanka, in the country’s Southern Province along the southern coast of the island. Hambantota is the country’s second largest port, after the Port of Colombo in the capital city. Construction for the port started in 2008, after the newly-elected President Mahinda Rajapaksa revitalized plans for the project by securing a loan of $306.7 million from China’s Export-Import (Exim) Bank and specified the China Harbour Engineering Company as the construction contractor. The first phase, out of three, of construction was finished in 2010, after the end of the Sri Lankan Civil War. Features of the first phase included a bunker terminal with the capacity of 500,000 tonnes of cargo, refueling stations for ships and aircraft, and ship repair/ship building facilities. The second phase of construction began in 2012, after the Sri Lankan Government gained an additional $757 million loan from China’s Exim Bank that allowed China Harbour Engineering Company and China’s Merchants Port to jointly operate the port for 35 years. As of present day, the second phase of construction is still unfinished and in 2016, President Maithripala Sirisena entered an agreement with China to sell 80% of shares, worth $1.12 billion, and a 99-year lease to China to take over ownership of the port to counter Sri Lanka’s $8 billion debt to China. Since this new deal, China’s Merchants Port have secured 15,000 acres of land surrounding the port to construct industrial zones, and the Chinese Navy has been using the port as a naval base for their submarines and to exert control over key maritime trade routes between the Strait of Malacca and the Suez Canal that sit just a few nautical miles from Hambantota.

The construction of the international port in Hambantota, and subsequent Chinese involvement, have been strife with controversy and reports of corruption. While the feasibility reports from both Canadian engineering firm SNC-Lavalin and Danish consulting firm Ramboll confirmed the economic benefits of the port, Former President Rajapaksa ignored their guidance and attempted to fast track construction without much profit. After its first year of opening, only 34 ships berthed at Hambantota, as opposed to 3,667 at the Port of Colombo. Concerns over Chinese involvement have also arisen out of the construction of this port, with Sri Lankan officials denouncing China’s exorbitant costs and extremely high interest rates. Many call Hambantota International Port a prime example of Chinese “debt-trap diplomacy” and accuse China of extending debt over Sri Lanka to gain political leverage to establish naval bases in the geopolitically strategic region. Additionally, Former President Rajapaksa has been accused of corruption, citing that he used funds for the construction of this project to provide kickbacks for himself and campaign officials.

Map of Location

[edit | edit source]

Actors

[edit | edit source]- Sri Lankan Government Actors

- Ranil Wickremesinghe - Prime Minister of Sri Lanka from 1993-1994, 2001-2004, 2015-2018, 2018-2019 and in 2022. President of Sri Lanka from 2022-2024.

- Mahinda Rajapaksa - President of Sri Lanka from 2005-2015. Prime Minister of Sri Lanka from 2004-2005, 2018 and 2019-2022. Minister of Finance from 2005-2015 and 2019-2021. President Rajapaksa is also from Hambantota.

- Gotabaya Rajapaksa - President of Sri Lanka from 2019-2022, and also Former President Mahinda Rajapaksa’s brother.

- Maithripala Sirisena - President of Sri Lanka from 2015-2019.

- Ravi Karunanayake - Minister of Finance from 2015-2017.

- Sri Lanka Ports Authority (SLPA) - State-owned operator of major commercial ports in Sri Lanka.

- Chinese Actors

- China Merchants Group - State-owned enterprise that operates under the Chinese Ministry of Transport. Currently has 85% stake in the Port and has invested $1.12 billion into the port.

- China Merchants Port Holdings Company Limited (CMPHCL) - Subsidiary of China Merchants Group that oversees port operations, general and bulk cargo transportation, container and shipping business, air cargo, and logistics park operations.

- Colombo International Container Terminal Limited - Joint venture company between CMPHCL and SLPA that handles cargo in Sri Lanka’s capital city, Colombo.

- Hambantota International Port Group - Joint venture company between CMPHCL and SLPA that oversees operations of the port.

- China National Petroleum Corporation - State-owned oil and gas corporation that was one of the first contractors of the port, overseeing refueling facilities and oil tank projects.

- Huanqiu Contracting and Engineering Corporation - Subsidiary of the China National Petroleum Corporation that handles the construction of oil refineries and oil tanks.

- China Petroleum and Chemical Corporation (Sinopec) - State-owned and world’s largest oil refining company that operates the port’s bunkering facilities. Recently constructed an oil-refinery at the port.

- Export-Import (Exim) Bank of China - Policy bank of China under the State Council that was the main financier of the port project.

- Li Ruogu - President of the Exim Bank from 2005-2015.

- China Development Bank - Subsidiary of the Exim Bank that raises funds for infrastructure projects.

- China Communications Construction Company (CCCC) - State-owned engineering and construction company that designs, constructs and operates infrastructure assets such as highways, bridges, tunnels, railways, airports and ports.

- China Harbour Engineering Company - Subsidiary of CCCC that is the main contractor for construction of the port.

- People’s Liberation Army Navy - The Navy of the People’s Republic of China that has been using Hambantota Port to dock their military vessels and submarines.

- China Merchants Group - State-owned enterprise that operates under the Chinese Ministry of Transport. Currently has 85% stake in the Port and has invested $1.12 billion into the port.

- Additional Actors:

- Shivshanker Menon - Foreign Secretary of India from 2006-2009. Notably rejected Sri Lanka’s request to finance Hambantota Port.

- AtkinsRéalis Group Inc. (SNC-Lavalin) - Canadian engineering consulting firm that was the original contractor for construction of the Hambantota Port and first company to conduct a feasibility report on the prospects of building the port.

- Rambøll Group (Ramboll) - Danish engineering consulting firm that was hired by Former President Rajapaksa to conduct a second feasibility report on the prospects of building Hambantota International Port.

Timeline

[edit | edit source]- December 5th, 2001 - Parliamentary elections are held in Sri Lanka. Ranil Wickremesinghe is elected Prime Minister and he and the United National Front pledge to build another seaport to ease traffic on the Port of Colombo.

- June 2002 - The Sri Lankan Government invited both the Canadian International Development Agency and the Port Autonome of Marseille to conduct feasibility reports on constructing a new port. SNC-Lavalin of Canada submits a feasibility report, but both France and Canada ultimately decide to not follow through with any investment due to the tense political climate of Sri Lanka.

- 2005 - Newly-elected President Mahinda Rajapaksa hires Danish consulting firm Ramboll to conduct an additional feasibility report for building a port in Hambantota, the president’s hometown. From this, the project is broken down into three phases. After both India and the United States rejected Sri Lanka’s requests for financing, China was approached and accepted the offer. Huanqiu Contracting & Engineering became the first construction contractor after a deal was signed between the two parties.

- July 2006 - Sri Lankan officials meet with Li Ruogu at the Exim Bank where Chinese officials encourage the usage of concessional loans to finance the project.

- February 2007 - President Rajapaksa visits China to finalize loan deals for the port. Exim Bank agrees to fund 85% of the project, or $307 million with SLPA covering the other 15%, or $53 million.

- January 2008 - Sri Lanka hires China Harbour Engineering Company to construct the first phase of the port, and construction begins.

- November 18th, 2010 - After rushed construction, the first phase is completed and the port is limitedly opened on the President’s Birthday.

- November 2011 - Sri Lanka pays China $40 million to blast a boulder blocking the usage of the port a year after opening.

- September 17th, 2012 - Exim Bank loans Sri Lanka an additional $809.35 million for construction of the second phase. The new loan agreement also allows China Harbour Engineering and China Merchants Group to jointly operate the terminal and take 65% stake for 35 years and the first loan receives a 6.3% interest rate.

- 2014 - Hambantota Port was struggling financially and could not attract businesses to dock there. China began demanding loan repayment for construction of the port, which Sri Lanka could not pay due to the lack of profit.

- November 2014 - Chinese military submarines begin docking at the port.

- January 8th 2015 - Sirisena is elected into office, and takes on the country’s $64.9 billion debt.

- December 2016 - SLPA & CMPHCL sign an agreement to sell China 80% of the shares, or $1.12 billion, of the port for a 99-year lease, including all land of the property.

- May 2017 - Sri Lanka takes out an additional $1 billion loan out of the China Development Bank to help pay back debt.

- July 2017 - Opposition parties in Sri Lanka denounce the agreement between the SLPA & CMPHCL, and a new agreement is reached that states that the Chinese company must divest a maximum of 20% within the next decade to Sri Lankan enterprises. Also, the new agreement bars foreign countries from docking military vessels at the port, at the request of India.

- July 2018 - Sri Lanka moves a naval base to Hambantota, raising concerns from India and the United States.

- 2019 - China Merchants Group announces a 136% increase of vessel usage at the port and fully automates and expands facilities.

- May 2024 - Hambantota Port has become a main shipping importer of cars into Sri Lanka, with a monthly turnover of 700,000 vehicles. Chinese-owned oil refineries have opened at the port and the port has become much more economically feasible.

Funding and Financing

[edit | edit source]The construction of the Hambantota International Port has been financed through a private-public partnership with a joint venture between the Sri Lanka Ports Authority and the China Merchants Group. Originally, SLPA had full ownership over the port, but as the 2016 agreement between the SLPA and China Merchants subsidiary China Merchants Port Holdings Company states, CMPHCL owns 80% of shares, with SLPA owning the other 20%. The construction of the port was also largely financed through a set of buyer’s credit loans (BCL), preferential buyer’s credits (PBC) and government concessional loans (GCL) from the China Export-Import Bank. The first of these loans amounted to $551.58 million on December 30th, 2007. This loan, for the first phase of the project, originally accrued an interest rate of around 2%, but was then raised with the onset of the second loan to 6.5%. The second loan reached $808 million, which was agreed upon on September 17th, 2012, with a much lower interest rate of 2%.

Notably, the funding for this project has also faced extreme controversy. It was found that the exorbitant costs and interest rates were uncontested by the Rajapaksa Administration. For example, China Harbour Engineering Company, one of the contracted construction companies, charged Sri Lanka $40 million to remove a boulder blocking usage of the port in 2010. Diplomats criticized the expensive cost, citing that the companies were overcharging. It was also found that $7.6 million in the port construction fund were directly given to Rajapaksa campaign aides, with an additional $1.7 million given to Rajapaksa himself.

Institutional Arrangements

[edit | edit source]In the early 2000's the Sri Lankan government had the idea to build a deep sea port in Hambantota as way to boost their economic growth. This project was originally to be overseen by a government owned entity called The Sri Lanka Ports Authority (SLPA), the project was missing funding which is why Sri Lankan government sought investments from countries like the USA and India and when denied ultimately led them to fall into Chinas Debt trap diplomacy. Debated by many sources it is argued that Chinas intentions were not to take over the port, but ultimately in a common series of event the Chinese investment overwhelmed the Sri Lankan Government and entities who could not afford the port thus leading to the Sri Lankan Government to lease the port to (CMPorts) China Merchant Ports Holdings with a deal valued at approximately 1.1 Billion which would only provide short term relief for their financial debt, and losing them control over one of their most valuable and tactical assets, and this is what causes this situation to be identified as a Debt trap diplomacy move from the Chinese. Even though he Sri Lankan authorities still hold ownership over the port, CMPorts holds the majority authority and is the primary operator of the port after originally the Sri Lankan port authorities were to operate the port. This is an example used among the world to describe Chinas Debt trap Diplomacy and also a failure of a Public-Private Partnership (PPP) between Sir Lankan government owned entities and Chinese Private entities in the form of CMPorts.

Impacts and Operations

[edit | edit source]The impact the Hambantota port has had on Sri Lanka is vastly complicated to say the least because whilst it has created a great financial strain for the nation, It has also opened up many job opportunities in an area previously lacking in development for the people on this side of the country starting from construction, to operations, Transportation, etc.. opportunity which has given a boost to the economic state of Hambantota. Despite the enormous amount of Debt taken on by Sri Lanka to make this piece of infrastructure come to life, a very strategic and valuable asset how now failed to meet the expected traffic and use in order to bring in that economic boost so sought after. Ending and yet another strain for Sri Lanka now dependent economically by Chinese Entities. Not just economically dependent for the debt owed to the Chinese but also dependent on their operation of the port after seeing them sign a 99 year lease to CMPorts a Chinese State owned entity, has given commercial operational authority to the Chinese thus also being dependent on their efforts to bring in revenue to help relieve the financial strain already being faced.

Background

[edit | edit source]Originally, the Sri Lankan government had teased the idea of building a new port in the underdeveloped south as far back as the 1970s, however, after the 2001 parliamentary elections, newly-elected Prime Minister Ranil Wickremesinghe announced the “Regaining Sri Lanka Economic Development Program”, which identified Hambantota as the site for the new international shipping port. In the following year, the Sri Lankan Government approached the Canadian International Development Agency to help finance the construction of the port. The Canadian Agency then agreed to the plan and financed the Canadian engineering firm SNC-Lavalin to conduct a feasibility report into whether building the port in Hambantota would be economically beneficial. The report supported Wickremesinghe’s ambitions in building the port, but plans failed to move forward due to Canada’s unwillingness to finance the project over concerns of contentious politics amidst the then ongoing Sri Lankan Civil War.

During his campaign for president in 2005, Mahinda Rajapaksa pledged to construct a new deep-water commercial port in his hometown of Hambantota, as an effort to ease traffic in Colombo’s shipping port, as well as bringing industry and revitalizing his underdeveloped home district. After being elected, Rajapaksa hired Danish consulting firm Ramboll to conduct a feasibility report on constructing a new international port in his hometown. Ramboll confirmed Rajapaksa’s plans by outlining a three-phase program in implementing the construction of the port through public and private partnerships. Rajapaksa used this report as means of evidence for his goals, and approached India and the United States with requests to finance this project. Both nations declined, and finally, Rajapaksa approached China, who then pledged to finance the port.

Narrative of the Case

[edit | edit source]Hambantota Port in Sri Lanka which started off as a project to gain a highly valuable asset for the country in various ways and a economic boost, how now become a valuable piece of infrastructure, and a controversial topic following the events occurred between Sri Lanka and the Chinese parties, now has spiked debated on the topics of international investment and Debt. Sri Lanka's Hambantota port a very valuable piece of infrastructure because of its strategic position and easy access to trade routes in the indian ocean is now in the control of the Chinese after signing a 99 year lease which was a last resort after being heavily in debt to Chinese investment parties which many believe was planned and many argue was not intentional.

Policy Issue

[edit | edit source]- “Debt-Trapping Diplomacy”

- Many diplomats and scholars cite this port as one of the most notable examples of China’s new “debt-trapping diplomacy” policy tactics by indebting less economically-advantaged countries with massive infrastructure projects at extremely high interest rates, and then demanding repayment in a short amount of time which the debted country cannot repay. The incumbent Sirisena Administration cited that they aimed to appease India and the West but had no other option than to continue to turn to China because their debt was so high. This also plays into the broader picture of the current ongoing power competition between China and the United States, as well as between China and India. Both countries have expressed concerns over China’s growing presence in the country, especially India. Indian officials went so far as to demand Sri Lanka to include a clause in their agreement with China that foreign militaries cannot use the port in Hambantota, however China has consistently violated this clause.

- Chinese authorities and Hambantota International Port Group (HIPG) officials refute the claim that China is preying on smaller countries, citing that they were able to “pay” China $1.12 billion in equity for the port instead of racking up interest rates and plunging further into debt. China has also stated that their only mistakes were investing in countries run by “corrupt politicians.”

- Modern-Day Imperialism

- China’s seizure of this port, as well as the presence of Chinese naval vessels in the port paint a concerning picture that looks eerily similar to European colonial practices back in the 14th and 15th centuries. Hambantota being only a few nautical miles from shipping lanes that account for 80% of cargo between Asia, Africa and Europe highlight the region’s, and country’s, geopolitically advantageous position. China was also extremely quick to include the port in Hambantota as part of their “Belt and Road Initiative”, which has raised alarms across the West.

- Corruption

- The construction and maintenance of Hambantota International Port has been rife with reports of corruption. President Rajapaksa, who spearheaded the development of this port, was caught numerous times providing himself, his brothers, his campaign team, and supporters with kickbacks worth over millions of dollars from funds that were loaned from the China Exim Bank for construction of Hambantota.

Takeaways

[edit | edit source]The Hambantota port will continue to be a valuable piece of infrastructure today and in the future due to its very strategic location, Indian ocean access, deep water, and large vessel accessibility. The port brings forward many debated which allows us to take note of many different events that occurred like Debt trap diplomacy which is what china is accused of doing throughout this project by using debt or financial leverage to take over an asset, we see International investment and debt, some would say a failure of Pubic-Private Partnership (PPP), and Risks of being over reliant on external debt and in this case nationally external.

Discussion Questions

[edit | edit source]Was this an intentional effort from Chinese parties to use financial leverage to obtain a strategically valuable asset?

Was this the only option Sri Lanka could have taken to build this port?

Was this a successful or unsuccessful example of Public-Private Partnership?

What could China do with this piece of infrastructure they are in control of?

Reading for discussion

[edit | edit source]1) Questioning the Debt-Trap Diplomacy Rhetoric surrounding Hambantota Port

2)Debunking the Myth of ‘Debt-trap Diplomacy’

https://www.chathamhouse.org/2020/08/debunking-myth-debt-trap-diplomacy/4-sri-lanka-and-bri

3)Understanding China’s Investments in Sri Lanka

References

[edit | edit source]- https://www.proquest.com/docview/2226279448?accountid=14541&parentSessionId=j9ntRURPS%2B6ndWsfaz0O2btZvx3Wd1Cobq1%2B3UXeGvE%3D&pq-origsite=primo&sourcetype=Wire%20Feeds

- https://www.proquest.com/docview/3035425392?accountid=14541&parentSessionId=r%2F%2BIxUQTJUcp0t73%2Fsdugi%2FxWhP0angMhNdAngsod7w%3D&pq-origsite=primo&sourcetype=Wire%20Feeds

- https://www.proquest.com/docview/734628251?accountid=14541&parentSessionId=ACY2UtpG12VEk1%2BoqjTBybXO7T6MEQ029VLrEg4Bt9E%3D&pq-origsite=primo&sourcetype=Wire%20Feeds

- https://www.csis.org/analysis/game-loans-how-china-bought-hambantota]

- https://www.nytimes.com/2018/06/25/world/asia/china-sri-lanka-port.html

- https://www.maritimeindia.org/View%20Profile/636276610966827339.pdf

- https://www.scmp.com/magazines/post-magazine/long-reads/article/3125914/narrative-surrounding-chinas-debt-trap-diplomacy

- https://web.archive.org/web/20100311180106/http://www.businessweek.com/news/2010-03-08/sri-lanka-to-seek-tenants-for-550-million-tax-free-port-zone.html

- https://www.ice.org.uk/what-is-civil-engineering/infrastructure-projects/hambantota-port-sri-lanka

- http://archives.dailynews.lk/2003/07/17/bus01.html

- https://www.sundaytimes.lk/031116/plus/6.htm

- https://china.aiddata.org/projects/65812/

- http://www.hipg.lk/about-us/public-private-partnership

- https://web.archive.org/web/20210304112527/https://www1.hkexnews.hk/listedco/listconews/sehk/2017/0725/ltn20170725444.pdf

- https://www.reuters.com/world/asia-pacific/chinese-military-survey-ship-docks-sri-lanka-port-2022-08-16/

- https://gjia.georgetown.edu/2021/06/05/questioning-the-debt-trap-diplomacy-rhetoric-surrounding-hambantota-port/

Skyline Drive

This page is for a case study on the Shenandoah National Park scenic byway, Skyline Drive, created by Johnathan Selmer, Jay Shuey, and Guillermo Padilla. It is part of the GOVT 490-003 (Synthesis Seminar for Policy & Government) / CEIE 499-002 (Special Topics in Civil Engineering) class offered at George Mason University taught by Jonathon Gifford.

Summary

[edit | edit source]The idea of Skyline Drive was first suggested in 1924. In a report from the Southern Appalachian National Park Commission to Secretary of the Interior Hubert Work recommending the establishment of a national park in this area, it was pointed out:

- “The greatest single feature, however, is a possible skyline drive along the mountain top, following a continuous ridge and looking westerly on the Shenandoah Valley, from 2,500 to 3,500 feet below, and also commanding a view of the Piedmont Plain stretching easterly to the Washington Monument, which landmark may be seen on a clear day. Few scenic drives in the world could surpass it.”[31]

Under the joint supervision of the Bureau of Public Roads and the National Park Service, construction of Skyline Drive began in 1931. By September 15, 1934, the first section of the Drive, 34 miles long, was opened for travel. This made available an extensive region of the Blue Ridge in which was located the vast central portion of the proposed Shenandoah National Park extending from Thornton Gap to Swift Run Gap. Within a year more than one-half million visitors were attracted to this portion of the park.

Today, Skyline Drive has grown and now runs 105 miles north and south along the crest of the Blue Ridge Mountains and continues being the only public road through the Park – attracting over 1.2-million travelers annually.

Map of Location

[edit | edit source]

History/Timeline

[edit | edit source]- 1924: Southern Appalachian National Park Committee selects the site for a national park in the Blue Ridge Mountains of Virginia, leading to the establishment of Shenandoah National Park.

- 1929: President Herbert Hoover calls for the construction of a roadway along the Blue Ridge Mountains, initially proposed to be named Hoover Highway but later known as Skyline Drive.

- January 1931: Field survey for Skyline Drive begins.

- July 18, 1931: Official groundbreaking for Skyline Drive.

- Late 1932: Congress approves $1 million for the construction of Skyline Drive.

- 1933: Civilian Conservation Corps (CCC) is formed and contributes to the construction of Skyline Drive.

- Mid-1934: Section of Skyline Drive between Thornton Gap and Swift Run Gap opens.

- 1935: Shenandoah National Park officially established, CCC continues construction on Skyline Drive.

- October 1, 1936: Skyline Drive completed between Front Royal and Thornton Gap.

- August 29, 1939: Portion of Skyline Drive from Swift Run Gap to Jarman Gap opens.

- August 11, 1939: Completion of the Blue Ridge Parkway section between Jarman Gap and Rockfish Gap, later incorporated into Shenandoah National Park as the southernmost portion of Skyline Drive in 1961.

- 1950s: Original chestnut log guardrails on Skyline Drive removed and not replaced.

- 1958: Marys Rock Tunnel partially lined with concrete.

- 1983: Federal Highway Administration begins work to replace original stone walls on Skyline Drive with concrete walls.

- April 28, 1997: Skyline Drive added to the National Register of Historic Places.

- September 22, 2005: Skyline Drive designated a National Scenic Byway.

- October 2008: Skyline Drive designated a National Historic Landmark for its role in the development of national parks in the eastern United States.

Funding and Financing

[edit | edit source]- Official groundbreaking was July 18, 1931, although the actual field survey began in January of that year.

- First section of construction initially was to be from Rapidan Camp to the Skyland Resort, some twenty miles, but evolved into the 34 miles from Swift Run Gap (U.S. 33) to Thornton Gap (U.S. 211). Original funds were allocated by the Federal Drought Relief Administration to employ Virginia farmers and apple pickers suffering from the severe drought impacts on the apple and produce harvests in 1930.

- Congress appropriated $1,000,000 the fall of 1932 to continue construction of the Drive and the Department of the Interior announced that the Drive would extend from Swift Run Gap to Front Royal.

- Roosevelt formed the Civilian Conservation Corps and the first two companies in the National Park Service were formed at Skyland (NP-1) and Big Meadows (NP-2). Shenandoah National Park would eventually benefit from ten CCC camps. May, 1933.

- Skyline Drive from Thornton Gap to Swift Run Gap was completed in the summer of 1934 and opened to the public on September 15, 1934. This section cost $1,570,479 or approximately $39,000/mile.

- Skyline Drive from Thornton Gap to Front Royal (32 miles) was opened to the public on October 1, 1936 and cost $ 1,235,177 or approximately $42,000/mile.

- Skyline Drive from Swift Run Gap to Jarman Gap (32.4 miles) was opened to the public on August 29,1939 and cost $1,666,528 or approximately $51,500/mile.

- Skyline Drive (then Blue Ridge Parkway) from Jarman Gap to Rockfish Gap (8.5 miles) was completed on August 11, 1939 and cost $358,636 or, approximately, $40,000/mile. [The southernmost section of the Drive from Jarman Gap to Rockfish Gap was originally constructed in 1938-1939 as a part of the Blue Ridge Parkway and was deeded to Shenandoah National Park in 1961.[32]

- Fees are collected at entry points to Skyline Drive (Front Royal, Thornton Gap, Swift Run Gap, Rockfish Gap). Pass options include:[33]

- $30.00 for a seven-day pass for private non-commercial vehicles

- $25.00 for motorcycles, $15.00 for individuals 16 and older (not in private non-commercial vehicles)

- Commercial tours pay between $25.00 and $200.00 based on passengers

- Annual park pass: $55.00 for private non-commercial vehicles

- America the Beautiful Pass options:

- Annual Pass: $80.00

- Annual Senior Pass: $20.00

- Lifetime Senior Pass: $80.00

- Lifetime Access Pass (free for persons with disabilities)

- Volunteer Pass (free for 250 service hours)

- Free Annual Pass for U.S. Armed Forces members

- Free admission for fourth graders' families with the Every Kid in a Park Pass.

Institutional Arrangements - Oversight and Maintenance

[edit | edit source]Key Actors and Institutions involved with the development and maintenance of the Skyline Drive include:

- National Park Service (NPS): The designated federal agency responsible for the oversight and maintenance of the entire Skyline Drive.

- Department of the Interior (DOI): The parent agency that the NPS resides under, DOI directs funding towards NPS projects and collects fees from each park that the NPS administers.

- Southern Appalachian National Park Committee (SANPC): SANPC played a pivotal role in informing the general public about the overarching national park system and specifically about the creation of Southern Appalachia, as legislated by Congress.

- Civilian Conservation Corps (CCC): The CCC provided the necessary labor force for the construction of Skyline Drive, receieved financial backing, and oversaw the implementation of the scenic byway.

- Federal Highway Administration (FHA): FHA contributed to the design and provided some oversight during the construction of Skyline Drive. Given its jurisdiction over Federal lands, the FHA ensured compliance with its established standards throughout the development of Skyline Drive.

Narrative of the Case

[edit | edit source]In the late 19th century, widespread exploitation of natural resources, particularly in the Western regions, prompted growing concerns regarding wasteful practices and the need for conservation measures.

President Theodore Roosevelt emerged as a leading advocate for conservation, making calls for federal oversight of resources and the protection of wilderness areas. Collaborating with influential figures such as John Muir, founder of the Sierra Club, advocated preservation of natural resources from use, while Gifford Pinchot, a forester, called instead for conservation, the proper use of natural resources. Together, environmentalist advocacy of different types led to the establishment of the National Park Service by Congress in 1916, and the preservation of areas including Yosemite and Yellowstone. In addition, the Roosevelt administration implemented significant policies, notably the Newlands Act of 1902 and the establishment of the National Conservation Commission in 1909.[34][35]

The proposal for a ridge road along the Blue Ridge mountains in Virginia was initially embraced as part of a new National Park plan in 1924. However, it sparked intense controversy within the conservation community. Benton MacKaye, a key figure in conservation, opposed the road, fearing it would disrupt the wilderness. On the other hand, Myron Avery, known for his leadership in trail construction, supported the road's inclusion in the Skyline Drive project. Their clash highlighted differing views on wilderness preservation versus accessibility.

Despite MacKaye's objections, the road was built, deepening the divide between preservationists and those advocating for broader public access to nature. The conflict underscored the complexities involved in balancing conservation objectives with societal interests. While MacKaye emphasized preserving the untouched wilderness of the Appalachian region, Avery prioritized practical trail construction and public engagement. Their disagreement left a lasting impact on the history of conservation in the United States, serving as a significant chapter in the evolving narrative of wilderness preservation.[36]

Policy Issues

[edit | edit source]Environmental Impact & Wildlife Management:

The way Shenandoah National Park has approached their environmental and wildlife management has evolved over time to address challenges from increased human activities, including as they pertain to Skyline Drive. A scenic byway stretching 105 miles through the park, Skyline Drive aimed to provide visitors with stunning views of the Blue Ridge Mountains from the comfort of their vehicles. However, this monumental undertaking altered the landscape and ecosystems and created long-lasting consequences for the park's natural environment.

The construction phase of Skyline Drive involved extensive land clearing, grading, and paving, which resulted in the destruction and fragmentation of local habitats [37]. Habitat fragmentation impedes the movement of wildlife populations, inhibits gene flow between isolated habitats, and increases the vulnerability of species to extinction. Forested areas were cleared to make way for the roadway meanwhile excavations and the construction of bridges and retaining walls altered the park's natural drainage and rate of soil erosion [38]. Skyline Drive's ongoing use as a popular tourist attraction and recreational thoroughfare has continued to impact Shenandoah National Park's environment and wildlife. Influxes of traffic along the roadway introduced air and noise pollution, which disrupted wildlife behavior, and posed risks to pedestrian safety. Regular road maintenance, such as asphalt resurfacing and roadside vegetation management, continue to act as a catalyst of environmental degradation. Invasive species along road corridors pose a threat to native plant communities and exacerbates competition for resources.

Despite these environmental challenges, legislation such as the Clean Air Act, enacted in 1970, have provided regulatory frameworks for environmental protection in Shenandoah National Park. The Endangered Species Act of 1973 required the protection of at-risk species like the Shenandoah Salamander [39]. Recent technological advancements allow park officials to evaluate management effectiveness and monitor wildlife, habitat, and ecosystem health more closely. The SWAS-VTSSS (Stream Water and Sediment Chemistry, Virginia Tech School of Forestry and Wildlife Sciences) monitoring program, initiated in 1979, plays a crucial role in evaluating water quality and ecological conditions in mountain streams affected by Skyline Drive and other anthropogenic activities [40]. The program contributes to evidence-based and adaptive management practices in Shenandoah National Park by collecting comprehensive data on stream water chemistry, discharge rates, and ecological responses. The National Park Conservation Association's (NPCA) "Polluted Parks Report" underscores the ongoing challenges posed by air pollution in Shenandoah National Park [41]. Despite its designation as one of only 49 Class I air areas managed by the National Park Service, the park continues to experience significant air quality concerns stemming from external sources of pollution [42]. Efforts to address air quality concerns involve sophisticated monitoring systems, regulatory compliance, and collaborative initiatives to reduce pollution levels and preserve the park's natural resources.

Land Acquisition & Eminent Domain:

The policy of land acquisition and eminent domain for the creation of Shenandoah National Park was a multifaceted and contentious process that unfolded over several years in the 1930s. Discussions about the park's creation began in 1924, but it wasn't until February 1, 1934, that the federal government under Arno Cammerer, director of the National Park Service, announced that the government would not accept land for the park from the state of Virginia until all residents had left the area.

In 1928, the Virginia legislature passed a condemnation law which allowed the state to acquire land for park via eminent domain. However, the law faced opposition from landowners who felt undervalued by the state's appraisal process. By 1933, landowners owning about 20,000 acres of land had contested the appraised values, leading to appeal hearings and delays in the acquisition process. The blanket condemnation law also faced legal challenges, most notably in the case of Robert H. Via, who sued the state on constitutional grounds citing the Equal Protection Clause of the 14th Amendment. Although Via's appeal was ultimately rejected by the Supreme Court in November 1935, his legal battle slowed the land acquisition process. Furthermore, an estimated 268 families living in Shenandoah at the time had no legal claim to the land they had inhabited for generations. The total number of families affected by the removals and resettlement efforts exceeded 500.

The "buy an acre" campaign was another significant facet of the park's creation. This campaign aimed to raise funds for land acquisition through public donations. Led by the Shenandoah National Park Association, park backers initiated a campaign aimed at persuading Virginians from around the state to contribute to the land fund. With a slogan advocating that Virginians "Buy an Acre" for $6.00, the fundraising drive raised nearly $1.2 million dollars. Approximately $1 million of funding came from state appropriations at the urging of Governor Byrd. Park enthusiasts also tried to secure donations from noted philanthropists. Carson had hoped to raise $2 million dollars from these notable figures, but only won a small percentage of that amount. With celebrity philanthropists largely absent from the list of supporters and with the onset of the Depression in 1930 sharply curtailing other fundraising efforts, park supporters had raised only slightly more than half of the estimated $4 million dollars needed to purchase the 321,000 acres. Consequently, Carson once again prevailed upon Congress to reduce the park's size. In 1932, Congress made its final acreage reduction, drastically reducing the minimum acreage needed for the park to be established to 160,000 acres, less than one-third the original congressional authorization mandated.

The removals began in earnest after the federal government officially accepted title to 176,429.8 acres of land from Virginia on December 26, 1935. By early 1938, fewer than four years after Cammerer's removal order, between 500 and 600 families had permanently left their homes in the park. The removals were often met with resistance, resulting even with some families needing to be forcibly evicted by local law enforcement.

Initiatives were undertaken to assist displaced families in resettling. One such initiative was the Federal Homestead Corporation (FHC), which initially aimed to establish homesteads for former residents. This initiative was stalled due to its extensive bureaucratic process and legal issues. The project was later revived under the Resettlement Administration (RA) in 1937. Efforts of the RA resulted in the construction of homesteads in locations across Page, Greene, Madison, Rappahannock, and Rockingham county and were estimated to cost $6,000 per homestead. Of the more than 500 families affected by removals, only 170 families qualified for and were placed in these homesteads. However, the homesteads included mortgages and monthly bills to which many of these discplaced families were unaccustomed to. Within two decades, none of the original mountain families remained within their resettlement homesteads[43].

Key Lessons and Takeaways

[edit | edit source]In the broader context of national parks, large government projects such as Skyline Drive are an example of planners and policymakers utilizing the government's sole authority to acquire private property for public use through eminent domain. Eminent domain has always been and will remain a heated topic for debate within the United State’s legal system, with the pushback citing constitutional arguments for protections against the deprivation of life, liberty, and property, juxtaposed with the government’s authority to violate those said protections with reasonable cause and just compensation.

Skyline Drive in Shenandoah National Park serves as a stark reminder of the delicate balance between human development and environmental preservation in national parks. The construction and use of this scenic byway demonstrates the lasting effects that human activities can have on natural landscapes. The National Park Service has committed itself to spreading awareness of related environmental issues and promoting more sustainable practices to preserve America’s most treasured landscapes for generations to come.

Discussion Questions

[edit | edit source]1. How do you think the construction of Skyline Drive reflects the broader tension between preserving wilderness areas and making them accessible to the public?

2. How do you view the ethical and legal implications of eminent domain in the context of conservation efforts and public infrastructure projects?

3. How might compensation initiatives for eminent domain take into account the cultural and historical connections of individuals who lack a legal claim to the land they have called home for generations? Should those individuals be compensated?

4. Scenic roads through national parks offer a chance to experience nature up close. However, they also become arenas for tension among pedestrians, cyclists, and motorists, all vying for use of these spaces. How can policymakers balance the enjoyment of these roads for different users while ensuring safety and preservation of the natural environment?

5. Considering the current political climate, do you believe a project like Skyline Drive could be undertaken today? Would a venture of this nature, balancing preservation (protection against use) and conservation (proper use of natural resources), even be considered?

References

[edit | edit source]- ↑ "AirNav: KJFK - John F Kennedy International Airport". www.airnav.com. Retrieved 2024-10-20.

- ↑ a b c d e "30". JFK International Airport Redevelopment. Retrieved 2024-10-20. Invalid

<ref>tag; name ":1" defined multiple times with different content - ↑ a b c d e f "Proximocast: 20 minutes with Jenn Aument, The New Terminal One". Proximo. Retrieved 2024-10-20. Invalid

<ref>tag; name ":2" defined multiple times with different content - ↑ "Exploring New York JFK Airport and History". flyive.com. 2024-02-16. Retrieved 2024-10-20.

- ↑ "Governor Cuomo Announces $13 Billion Plan to Transform JFK Into a World-Class 21st Century Airport". NYC DOT.

- ↑ a b c d e f g "Jennifer Aument Appointed Chief Executive Officer of The New Terminal One at JFK International Airport". Yahoo Finance. 2024-02-26. Retrieved 2024-10-20. Invalid

<ref>tag; name ":3" defined multiple times with different content - ↑ a b c d e f g Golata, Justine (2024-03-19). "Here's What JFK's Largest Terminal To Date Will Look Like". Secret NYC. Retrieved 2024-10-20. Invalid

<ref>tag; name ":0" defined multiple times with different content - ↑ "We Keep the Region Moving | Port Authority of New York and New Jersey". www.panynj.gov. Retrieved 2024-10-20.

- ↑ "About Ferrovial - The company's strategy and organizational structure". Ferrovial. Retrieved 2024-10-20.

- ↑ "The New Terminal One at JFK Announces $2.55 billion Green Bond Issuance". Yahoo Finance. 2024-06-27. Retrieved 2024-10-20.

- ↑ "Municipal Securities Rulemaking Board::EMMA". emma.msrb.org. Retrieved 2024-10-20.

- ↑ "Public Transportation Ridership Report, Second Quarter 2024" (PDF). American Public Transportation Association. September, 2024.

{{cite web}}: Check date values in:|date=(help) - ↑ a b c d e f Warerkar, Tanay (2018-10-04). "New looks at JFK Airport's forthcoming $13B overhaul". Curbed NY. Retrieved 2024-10-21. Invalid

<ref>tag; name ":4" defined multiple times with different content - ↑ U.S. Department of Transportation (May, 2024). "U.S. International Air Passenger and Freight Statistics" (PDF).

{{cite web}}: Check date values in:|date=(help) - ↑ "GOVERNOR HOCHUL CELEBRATES FINAL PHASE OF THE JFK TRANSFORMATION WITH GROUNDBREAKING FOR A NEW $4.2 BILLION TERMINAL 6". panynj.gov. Retrieved 2024-10-21.

- ↑ "GOVERNOR CUOMO ANNOUNCES PLAN TO BUILD $3.9 BILLION NEW TERMINAL 6 AT JFK INTERNATIONAL AIRPORT TO RESUME, MARKING MAJOR STEP FORWARD IN AIRPORT'S TRANSFORMATION". panynj.gov. Retrieved 2024-10-21.

- ↑ "New York Transportation Development Corporation Special Facilities Revenue Bonds, Series 2024 (John F. Kennedy International Airport New Terminal One Project)" (PDF). June, 2024.

{{cite web}}: Check date values in:|date=(help) - ↑ Lauria-Blum, Julia (2024-07-09). "Transforming a Global Gateway". Metropolitan Airport News. Retrieved 2024-10-21.

- ↑ "AlphaStruxure to Design, Construct, and Operate JFK's New Terminal One Microgrid, With Largest Rooftop Solar Array in NYC and Grid-Independent Operation". AlphaStruxure. Retrieved 2024-10-20.

- ↑ "PORT AUTHORITY AND THE NEW TERMINAL ONE CONSORTIUM KICK OFF CONSTRUCTION OF NEW YORK CITY'S LARGEST SOLAR ARRAY AT JOHN F. KENNEDY INTERNATIONAL AIRPORT". www.panynj.gov. Retrieved 2024-10-20.

- ↑ JFK, The New Terminal One at. "The New Terminal One at JFK Issues RFP for Professional Services Firm for Janitorial, Landscaping Maintenance, and Related Services". www.prnewswire.com. Retrieved 2024-10-20.

- ↑ "South Fork Wind Receives Federal Record of Decision, Setting Stage for New York's First Offshore Wind Farm to Begin Onshore Construction in Early 2022". southforkwind.com. Retrieved 2024-11-04.

- ↑ a b "LIPA-First-Offshore-Wind-Farm-Doc-V19_102819-FINAL" (PDF). Long Island Power Authority - LIPA. Retrieved 2024-10-31.

{{cite web}}: CS1 maint: url-status (link) - ↑ "About Interior | U.S. Department of the Interior". www.doi.gov. 2017-03-01. Retrieved 2024-11-04.

- ↑ "Ørsted and Eversource Joint Venture Approves Final Investment Decision for New York's South Fork Wind Offshore Wind Farm". us.orsted.com. Retrieved 2024-10-31.

- ↑ "OCS Lands Act History | Bureau of Ocean Energy Management". www.boem.gov. Retrieved 2024-11-02.

- ↑ "Construction Archive". southforkwind.com. Retrieved 2024-11-02.

- ↑ "Clean Energy Future | U.S. Department of the Interior". www.doi.gov. 2021-05-24. Retrieved 2024-11-04.

- ↑ "Renewable Energy". NYSERDA. Retrieved 2024-11-04.

- ↑ "Our offshore wind projects in the U.S." us.orsted.com. Retrieved 2024-11-04.

- ↑ Benson, Harvey (1940). "The Skyline Drive - A Brief History of a Mountaintop Motorway". National Park Service. Retrieved 2024-02-11.

- ↑ Engle, Reed (2022-12-09). "The Greatest Single Feature". National Park Service. Retrieved 2024-02-17.

- ↑ National Park Service (2024-01-17). "Fees & Passes". National Park Service. Retrieved 2024-02-18.

- ↑ Library of Congress (n.d.). "Conservation in the Progressive Era". Library of Congress. Retrieved 2024-02-15.

- ↑ Howard, Ella (2016). "Environmental Preservation in the Progressive Era". Digital Public Library of America. Retrieved 2024-02-15.

- ↑ White, Donald (2008-05-15). "ATC v Skyline Drive". South Shenandoah. Retrieved 2024-02-14.

- ↑ United States Geological Survey (n.d.). "Ecology of Shenandoah National Park". United States Geological Survey. Retrieved 2024-02-12.

- ↑ Jones, Jenny (2011). "Skyline Drive: Engineered With Nature in Mind". American Society of Civil Engineers. Retrieved 2024-02-13.

- ↑ National Park Service (2022-09-28). "Shenandoah Salamander". National Park Service. Retrieved 2024-02-13.

- ↑ University of Virginia - Department of Environmental Sciences (n.d.). "SWAS-VTSSS Program Overview". swas.evsc.virginia.edu. Retrieved 2024-02-16.

- ↑ National Parks Conservation Association (2019). "Shenandoah Polluted Parks Report". National Parks Conservation Association. Retrieved 2024-02-14.

- ↑ National Park Service (n.d.). "Air Quality Monitoring". National Park Service. Retrieved 2024-02-13.

- ↑ Virginia History (n.d.). "The Ground Beneath Our Feet – Shenandoah National Park". www.vahistory.org. Retrieved 2024-02-15.

Port Miami Tunnel

This page is for a case study on the Port Miami Tunnel, created by Xiyuan Tang, Yitong Zhou, and Yueying Cao. It is part of the GOVT 490-003 (Synthesis Seminar for Policy & Government) / CEIE 499-002 (Special Topics in Civil Engineering) class offered at George Mason University taught by Jonathon Gifford.

Summary

[edit | edit source]Port Miami Tunnel, located in Miami, Florida, is a vital transportation infrastructure project designed to improve connectivity and enhance traffic flow in and out of the Port Miami area. The tunnel was conceived to address the growing congestion and facilitate the movement of goods and people between the port and the surrounding areas.

Approved after decades of planning and discussion in December 2007, the project faced a temporary cancellation a year later. However, construction resumed, commencing in May 2010. Subsequently, the tunnel was opened to traffic on August 3, 2014. [1]

On a typical weekday, nearly 16,000 vehicles commute to and from Port Miami via downtown streets, with truck traffic constituting 28 percent of this vehicular movement. [2] Beyond facilitating expedited access for trucks and automobiles heading to the port, the Port Tunnel is strategically designed to optimize traffic flow in Downtown Miami.

The Port Miami Tunnel enhances accessibility to and from the Port, functioning as a dedicated roadway connector that links the Port with the MacArthur Causeway (State Road A1A) and I-395. [2] This tunnel is accessible to all, catering to both cruise and cargo traffic.

Maps of Location

[edit | edit source]

History/Timeline[3]