Wikijunior:How Things Are Made/Rubber/Tire

Appearance

Products

[edit | edit source]-

Tires for car

Tires (or tyres) are used to attached as most of the major transport vehicle wheels and are mostly made of rubbers.

What do we need to make this thing?

[edit | edit source]

Rubber is the main raw material used in manufacturing tires, and both natural and synthetic rubber are used.

Natural rubber is found as a milky liquid in the bark of the rubber tree, Hevea Brasiliensis.

The other primary ingredient in tire rubber is carbon black.

Carbon black is a fine, soft powder created when crude oil or natural gas is burned with a limited amount of oxygen, causing incomplete combustion and creating a large amount of fine soot.

What is the step by step process?

[edit | edit source]- Step 1: The first step in the tire manufacturing process is the mixing of raw materials to form the rubber compound. Gigantic mixers, hanging like vertical cement mixers, stir the rubber and chemicals together in batches

- Step 2: Each mix is then re-milled second time with additional heating to soften the batch and additional chemicals are mixed.

- Step 3: For third milling, the batch goes through a mixer again, here additional chemicals are added to form what is known as the final mix. During all three steps of mixing, heat and friction are applied to the batch to soften the rubber and evenly distribute the chemicals.

- Step 4: Once a batch of rubber has been mixed, it goes through powerful rolling mills that squeeze the batch into thick sheets. These sheets are then used to make the specific parts of the tire.

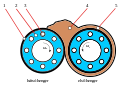

- Step 5: For the beads of a tire, wire bundles are formed on a wire wrapping machine. The bundles are then formed into rings, and the rings are covered with rubber.

- Step 6: The rubber for the tire tread and sidewalls travels from the batch mixer to another type of processing machine called an extruder. In the extruder, the batch is further mixed and heated and is then forced out through a die-a shaped orifice-to form a layer of rubber. Sidewall rubber is covered with a protective plastic sheet and rolled. Tread rubber is sliced into strips and loaded into large, flat metal cases called books.

- Step 7: The rolls of sidewall rubber, the books containing tread rubber, and the racks of beads are all delivered to a skilled assembler at a tire-building machine.

- Step 8: At the center of the machine is a collapsible rotating drum that holds the tire parts. The tire assembler starts building a tire by wrapping the rubber-covered fabric plies of the body around the machine drum. After the ends of these plies are joined with glue, the beads are added and locked into place with additional tire body plies laid over the beads. Next, the assembler uses special power tools to shape the edges of the tire plies. Finally, the extruded rubber layers for the sidewalls and tread are glued into place, and the assembled tire-the green tire-is removed from the tire-building machine.

- Step 9: A green tire is placed inside a large mold for the curing process. A tire mold is shaped like a monstrous metal clam which opens to reveal a large, flexible balloon called a bladder. The green tire is placed over the bladder and, as the clamshell mold closes, the bladder fills with steam and expands to shape the tire and force the blank tread rubber against the raised interior of the mold. During this curing process, the steam heats the green tire up to 280 degrees. The longer it is inside the mold, the harder the tyre will become.

- Step 10: The tire is placed on a test wheel, inflated, and spun. Sensors in the test wheel measure the balance of the tire and determine if the tire runs in a straight line.

-

Step 2: Rubber goes thru the milling process

-

Step 4: Rubber are squeezed through milling

-

Step9: Tire are put inside the mold for curing processes

-

Step 10: The tire are tested on test track to check for imperfections