Building Better Worlds in the 21st Century

- Dani Eder,

- The Seed Factory Project,

- 6485 Rivertown Rd, Fairburn, GA, 30213

- email: danielravennest@gmail.com

- May 2023

Note: Most of this report is now part of the more detailed two volume Better Worlds set.

- Introduction - Current national space programs are based on a limited vision of going to one place at a time for reasons like science and national prestige. Missions have finite goals and end when they are reached, so they don't include full development of the destinations. Instead, equipment and supplies come from Earth, which keeps costs high. Limited goals and high cost result in poor return on effort.

- In this report we propose a broader concept of upgrading and extending civilization on Earth first, then full development of the entire Solar System, and eventually beyond it. Our approach is based on self-improving production systems that grow from a starter set of core equipment called a Seed Factory. Seed factories make more equipment for themselves mostly using local energy and raw materials. This is in addition to making finished products like any other factory.

- Each location follows a growth cycle of self-improvement, making products for local use, trade with the rest of society, and becoming economically self-supporting. Once matured, the location sends elements of new starter sets to new locations. Locations are developed in logical progression from easier to harder and more distant.

- The very large physical space, materials, and energy resources beyond Earth enable large total returns. Since locations grow to support themselves, the net cost of such a program is only the initial start-up, so the return on effort is high.

- It isn't in the scope of this report to provide detailed plans and hardware designs. What we describe is a possible path that leverages self-improving production methods. This is a step towards solving existing problems and building a better future, but much more work is needed for this idea.

1.0 - Problems of Current Programs

[edit | edit source]

Governments have pursued space projects and programs, individually or in groups, for purposes like research, exploration, advancing technology, and prestige. While the results can be large, these efforts often suffer from outdated assumptions, high absolute costs, low relative return on effort, and a focus on single destinations. They have also often not leveraged new knowledge and technology.

- Outdated Assumptions

Sending people to the Moon and Mars are stated goals of US National Space Policy. Significant annual budgets are being spent towards these goals, primarily on the Space Launch System and Orion Spacecraft. The program concept to reach these goals is directly descended from plans first made in the mid-20th Century, such as Von Braun, 1954. In the decades since, the technologies to be used have advanced, but the overall concept has not. In NASA's Journey to Mars (Oct 2015), the "mission" approach includes a number of assumptions:

- It is a round trip for the crew, from Earth to Mars and back, with limited duration on the Martian surface.

- Because the number of missions is small and they are short, it is not economic to develop many local resources.

- Most or all equipment and supplies are launched from Earth.

- High cost limits mission mass. So crews have to accept risks from radiation exposure, equipment failure, and lack of fallback positions.

Other goals like the Moon and orbiting stations have similar limiting assumptions, and are considered separately from each other.

- High Cost

Government-funded and contractor-built space programs have little incentive on either side to finish promptly or keep costs under control. Project-oriented agencies want to continue their existence, but getting approval for new projects is hard. Contractors want to earn as much as possible, but winning new contracts by competitive bidding is uncertain. Politicians who decide on budgets want to preserve jobs in current locations, which works against cost savings.

The incentives on all sides have led to low cost estimates to get project approval. The tacit understanding is real costs will gradually be revealed as the work progresses. Spent funds deter cancellation as the full costs are revealed, because the funds would then be wasted on an unfinished project. This pattern avoids frequent approval for a new project or competing for new work. The project schedules are instead stretched to fit real cost to available annual budgets. The result is a few big "can't fail" projects. Public failures risk losing funding or even an agencies' existence. So projects must be conservative, slowing progress.

- Low Returns

In terms of exploration and science, a trip going to one place like Mars, and bringing back perhaps a few hundred kg of samples, is not much return for the effort expended. Relatively short round trips do not allow for full exploration of a landing site, much less a planet with the land area of Earth. Lack of refueling stations and reusable vehicles limits sample mass that can be returned to Earth, where researchers and laboratories can fully analyze them.

If most items have to be launched from the deep gravity well of Earth, then delivery costs will be high, and increase linearly with the number of missions. High transport cost limits weight, and in turn safety features like adequate radiation shielding, backup vehicles, and spare parts and supplies. To minimize risk, what is built must be both lightweight and near-perfect, which is also expensive. Despite that, crew risk is still high in absolute terms. The combination of low return and high cost have delayed going to the the Moon and Mars for decades. Such a program is now moving forward, but very slowly.

- Focus on the Moon and Mars

The Moon is nearby, big, and obvious to everyone on Earth. So it was a natural first destination for human exploration. Venus and Mars are the closest major planets. Venus was originally thought a suitable destination because of similarity of orbit, mass, and gravity. However it turned out to be very hot from a thick CO2 atmosphere. Mars then became the next focus of human exploration by being the most Earth-like and nearby destination.

The focus on Earth-like conditions ignores that on Earth, even the best places require some technology to survive, and more of it to be comfortable and flourish. At a minimum clothing, shelter, and agriculture, are needed, with their underlying technologies. For most of the Earth technology like ships, planes, and snow crawlers are needed to reach places, and more technology if you intend to stay.

Mars, or anywhere else in space, also require technology to survive and flourish. But Mars does not require dramatically more than harsh places on Earth. For example the temperatures on Mars overlap those of cold places on Earth, such as Siberia and Antarctica. At the same time, the surface of Mars isn't less difficult than other locations in space. Getting there needs more work than high orbits near Earth. The colder surface temperatures and 80% lower solar flux require more equipment than near Earth. A primary focus on the Moon and Mars over everywhere else is a mistake. They are large, interesting, and can be useful. So they should be part of future programs, but not to the exclusion of other places.

A new approach is needed that remedies the problems noted above. It should be based on up-to-date knowledge of the Solar System and new technologies developed since the mid-20th century. It should explore and use all of the many places in the Solar System. That includes the orbital and interplanetary spaces around and between natural objects. Finally, it should have high science and economic returns for the effort expended, including direct returns to people on Earth.

2.0 - New Knowledge and Technologies

[edit | edit source]

Our new approach starts with a modern overview of the Solar System and its resources. We then introduce technologies to access and use those resources. Self-improving production systems that become highly efficient with "Smart Tools" is key among these. Our intent is to use these to benefit civilization and the Earth's environment.

2.1 - The Modern Solar System

[edit | edit source]

The mid-20th century Solar System included 9 planets and their moons, plus a few thousand asteroids in the belt between Mars and Jupiter. Materials would be available on the surfaces of the Moon and Mars, but required significant fuel to take elsewhere. So they would only be used locally. Energy would come from solar-powered steam turbines, or a little later from fuel cells. These ideas are quite outdated and becoming more so each year.

Today we can inventory at the known Solar System in terms of its material and energy resources. Such Natural Resources on Earth are well-studied and understood. Most people know about the Moon, the other major planets, and that some of them also have moons. So here we will mainly review the more recently found and less familiar parts Solar System.

In terms of resource access, the smaller members of the Solar System all take less energy to land on and remove materials from than Earth. They also have greater surface area relative to mass and lower gravity, making extraction easier.

- Material Resources

Near Earth Objects (NEOs) are those which come closer than 1.3 AU to the Sun, where 1 AU is the Earth's average solar distance. Mars' orbit ranges from 1.38-1.67 AU, so NEO's are "on the way there" in terms of solar distance. In 1950 time there were 55 such objects known, of which only 13 were asteroids. The rest were comets, which are easier to find when they have large tails. The asteroids were ignored because their orbits were not ideal, and mining them was still a subject for science fiction.

This has changed dramatically. As of early 2023 there are over 31,500 known NEOs. The number has increased exponentially since about 1980 as better telescopes have been used to find them. These searches are partly driven by the impact risk such objects pose to Earth. Of those found so far, 853 are asteroids 1 km or larger in size, a nearly full count. 10,400 are larger than 140 meters out of an estimated 27,000 total. The rest are smaller, with perhaps 4 million yet to find larger than 10 meters (Trilling, 2017). 119 of them are comets, which lose material when close to the Sun. Just the largest handful of NEOs have a combined mass of 50 trillion tons, which is roughly a thousand years of mining activity on Earth.

The much larger numbers means more of them are in orbits easy to reach from Earth or on the way to Mars. Very efficient Electric Propulsion and other technologies unknown in 1950 time now exist. They make it possible to reach NEOs and work with them remotely from Earth, as recent asteroid and comet probes have done. Early research has been done on Asteroid Mining and Space Manufacturing to make use of their materials. Using NEOs as sources of propellants, supplies, and other products would greatly reduce what you need to bring from Earth for space projects.

Beyond those that come close to Earth, the Total Number of known objects in the Solar System, as of 2023, is 1.27 million. This is about 600 times what was known in 1950. The list of such Minor Planets has grown rapidly as new dedicated telescopes and search techniques were applied.

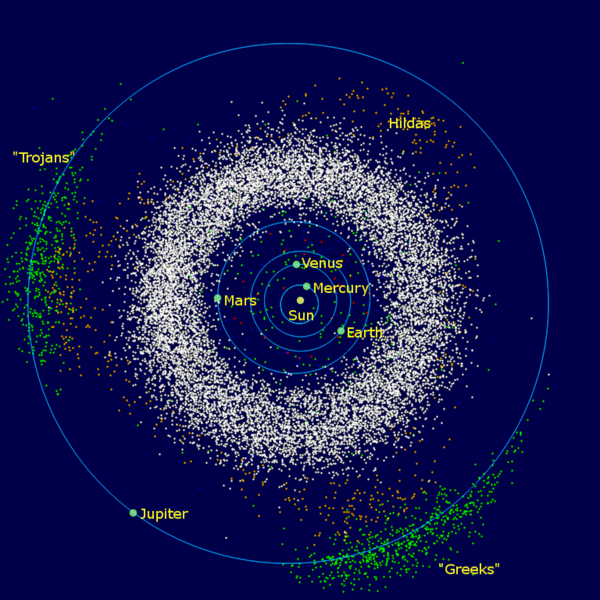

92.3% of known objects are in the Main Asteroid Belt between Mars and Jupiter (Figure 2.1-1), but many thousands of others are in orbits throughout the Solar System. The Minor Planet Center maintains information about all of them. The high proportion in the Asteroid Belt is a function of distance, not absolute numbers. Brightness decreases as square of both distance from the Sun and the telescope. So discoveries are strongly biased to nearby objects, and to only finding the largest ones at greater distances. But total number of objects goes up about 3,500 times when the size goes down by 100 times. So there are many more smaller objects still to be found.

Many of the objects discovered beyond Neptune, at 30-80 AU, have Eccentric Orbits. These objects tend to be found at the close end of their orbits, when they are bright enough to see. This additional discovery bias means there are many more like them waiting to be found, but are currently in more distant parts of their orbits, or never come close enough to find with current telescopes. The 2023 count of about 4800 such distant objects is limited to those larger than 100 km for the farthest ones. As search methods improve, many more such objects will be found at all distances and more of the smaller ones.

Near-Parabolic Comets can reach distances measured in light-years, or even escape the Solar System entirely. Aside from them, the known size of the Solar System has increased nearly 64 times since 1995, from 49.3 AU for Pluto to 3136.5 AU for the maximum distance of scattered object 2014 FE72. Some of these objects are quite large (Figure 2.1-2), and there is even a suspected major planet still to be found. Although the absolute distance of these objects is very large, the energy to reach them has a finite limit, as the five planetary probes Leaving the Solar System demonstrate. The practical limit is set by how long it takes to reach and use them.

The inventory of Solar System objects is now known to be incomplete, especially for small and distant ones. Despite this, there is detailed knowledge of the history, composition, and geology of some of its members, and this is constantly improving. We expect this to continue, especially from future mass-produced probes with efficient propulsion and refueling capability. Many more objects can then be visited than the current handful per decade. As more is learned about these objects, better plans on how to use them can be made. But even with current knowledge, a start on such plans is possible.

- Energy Resources

The Sun is an immense energy source, producing 20 trillion times what civilization uses today. That energy streams in all directions, not just at the objects which orbit it. Mining and building on the surface of Solar System bodies is convenient, but they typically gather half or less of the available solar energy. This is because of day-night cycles, geography, and in some cases atmospheres and eclipses from other bodies.

It takes significant energy to move materials from the larger bodies to open space, but once there, solar energy is available up to 100% of the time. For example, with current technology it takes about 480 MJ (134 kWh) to raise 1 kg from Earth to an orbit in full sunlight. Once there, 1 kg of modern space solar panel can extract that much energy in 56 days, but lasts about 100 times longer. Most solar system bodies are smaller than Earth, and there are more efficient ways to lift materials than today's rockets. So from a net energy standpoint it often makes sense to work in open space.

Solar cells were only 6% efficient in the mid-20th century, so solar-driven steam turbines were part of the original Mars mission concepts. Solar cells are now 47.6% efficient in the laboratory and 31% for space power applications, and continue to Improve. Using lightweight concentrating reflectors, they can be useful even in the outer Solar System. Where heat, rather than electricity, is needed, direct solar exposure or using mirrors can can reach 80% efficiency or higher.

In addition to solar, there are various energy sources that are more limited in scale and location. These include nuclear fission and potentially fusion, geothermal, and wind. On Earth we use hydroelectric and chemical combustion, but those are not generally available elsewhere. The orbital motion and gravity fields of bodies are not energy sources, but their potential and kinetic energy can be used in various ways. The Sun's output alone, which will last for billions of years, plus raw materials found all over the Solar System, are enough to sustain civilization and the Earth's environment.

- The Illusion of Scarcity

Current civilization is actually quite limited, even on Earth. The urban, forest, and farm land used in any significant way amounts to only 13.5% of the planet's surface. The remainder are oceans, deserts, and ice caps that are only traveled through or barely used. Of the part that is used, it is equivalent to a thin surface layer.

The world's biosphere (about 2000 Gigtons) plus the human built environment (about 1100 Gigatons) averages about 6 kg/m2, while the Earth's total mass to area is 11.71 billion kg/m2, or a ratio of one part in 2 billion. At the density of water, the biosphere plus civilization amounts to a 6 mm (1/4 inch) thick layer across the planet's surface. If we only consider the fraction of the planet used, the equivalent thickness is 7.4 times higher, or 4.4 cm (1.75 inches). If this number seems small, it is because most of us live in places that are built up. Life and civilization are very unevenly distributed. Cities and river dams, for example, have much higher built mass per area, while tropical forests can reach 25 times the average biosphere density per area.

The perceived scarcity of resources is an illusion, because current civilization uses only 2 billionths of the planet's mass and one ten-thousandth of the available energy flow. Photosynthesis uses about 13 times more available energy, but still only about 1/8%. In a literal sense we are only scratching the surface of our own planet. When we consider the whole Solar System, the available resources increase by hundreds of times in mass, and two billion times the energy that reaches Earth.

A larger fraction of smaller bodies is accessible. On Earth pressure and temperature limits going too deep. Bodies with lower gravity and less hot interiors can be accessed more deeply or all the way through. The much higher total energy across the Solar System would also allow reprocessing and reusing what we consider waste products today. Scarcity would not be a problem if these vast untapped resources could be used.

2.2 - New Technologies

[edit | edit source]

For our approach we want to use the best available production and space technologies, plus some new ones that can be developed in the near future. These include seed factories, production networks, space technologies that are already in use but not yet in government plans, and new ones for space not yet fully developed. This is in addition to more standard existing technology.

- Seed Factories

Production systems which use part of their output for self-improvement can grow exponentially. Production can start with simpler tools, but modern technology like computers, communications, automation, robotics, software, and artificial intelligence lets them become more efficient.

We call a starter set of tools and machines capable of self-improvement a Seed Factory. They grow to become mature factories by analogy to plant seeds, which grow into mature plants that can produce more seeds. Seed factories can improve in several ways:

- Making parts for additional copies of current equipment.

- Making new types of items not in the starter set, and

- Making different versions of existing equipment (larger, more accurate, etc.).

While modern technology can reduce the labor needed, some people are still needed today to operate the factory. Like any other factory, some part of its output is for sale or trade. This helps cover the initial cost and items it can't make internally.

The improvements increase production capacity and the range of products that can be made. Since the capacity to grow increases with the size of the factory, the growth is exponential. The starter or added equipment can include power generation, mining, and materials processing, so the factory can self-supply and self-power from local resources. A seed factory may not use any local sources to start with, but can approach 100% as it matures. Some parts and materials would likely be too hard to make, or too rare locally. So even for a mature factory they would still come from elsewhere.

When production at a given location is mature enough, it can start supplying parts for, or complete new starter sets. These can be set up locally or sent to new locations, repeating the growth process. Internal growth and making new starter sets highly leverages the initial cost. It fundamentally changes the return/cost ratio of projects for the better.

- Locations and MakerNets

When we refer to "locations" we mean a single environment type, with equipment and people that are close enough that they can work together and trade physical items easily. On Earth that might be a single metropolitan area. In less developed places it might be smaller in size from lack of easy local transport. Equipment in a given location may have different owners or control systems, but can still coordinate their work and cooperate on larger projects.

The collection of coordinating operations forms a network, which we call a MakerNet, after the modern Maker Subculture, who make things. The network has multiple communicating nodes, each of which includes a set of equipment and people who can do tasks. A MakerNet can extend over multiple locations, since data transfer and remote control can operate over long distances at low cost.

Physical transportation of people and supplies is not as easy, so we distinguish separate locations within a larger network. To the extent local sources can be used, it would lower transport costs. So there is an incentive to ship lightweight items like information over bulk materials.

- Space Technologies

New or improved space technologies have been developed since the mid-20th century, but not fully included in program plans. These include:

- Electric propulsion - which uses many times less propellant than chemical rockets. Using large tanks of propellant to deliver relatively small payloads has strongly limited space projects in the past.

- Better Materials - There are new and significantly improved engineering materials, including high strength fibers, and composite materials that use them. Production methods for them have also improved.

- Closed Loop Life Support - has been developed which recycles supplies using mechanical equipment or biology.

Additional technologies that were not specifically developed for space, but can be used for it, include small and powerful computers, their software, other kinds of electronics, robotics, automation, high speed communications, and most recently artificial intelligence (AI) applications.

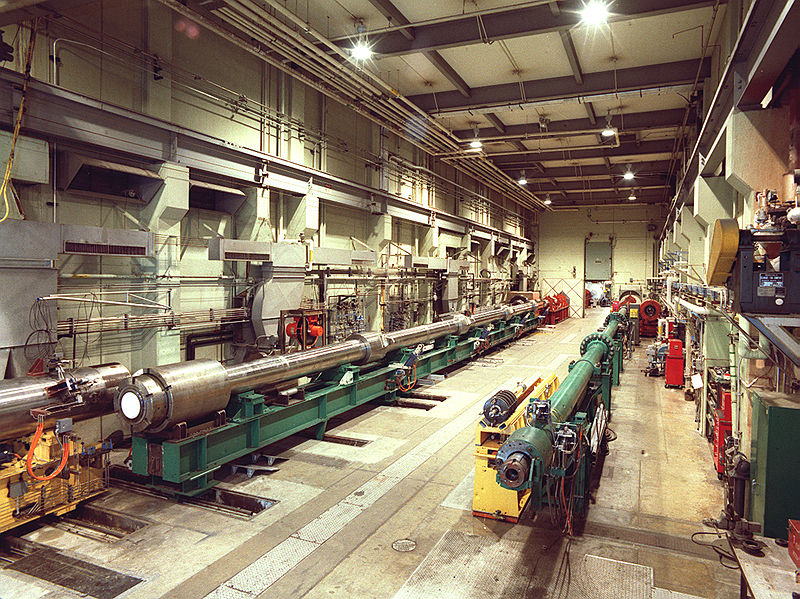

Many other space technologies have been proposed, but not yet fully developed. This is either from lack of money and resources, or not enough scale yet to justify them. MakerNets and seed factories can potentially overcome these limitations. Our second volume on Space Systems Engineering collects current and future space technologies that we know of, so they can be considered for future plans. Some transport examples are ground-based accelerators and air-breathing engines for reaching orbit, and rotating skyhooks for artificial gravity and orbit transfer.

3.0 - New Program Concept

[edit | edit source]

For discussion purposes we refer to this as a program, with component phases and projects. But we do not expect it to all be under centralized government direction. Instead it would also include independent businesses operated for profit, public/private partnerships, incentive prizes, and other alternatives.

This section summarizes our goals and approach. The rest of this report, and our other documents, provide more details. This is a work in progress. It is by no means a finished proposal or a final design. It likely never will be, as the future brings new discoveries and technologies. We have identified new goals and methods, and made a start at the details, but much more work is needed. Our work is open-source, so feel free to build on it, provide feedback, and contribute your own ideas.

- Goal 1 - Benefits on Earth

Existing government space program goals are mainly for science, exploration, and national prestige. They have limited budgets because they compete with other government priorities. Our approach is to go beyond these limits, to include the full range of civilized activities, both on Earth and in space. About billion times more people live on Earth right now than in space, and their needs are much larger and more immediate. So our first goal is to address problems on Earth, starting with easier ones and then towards the more difficult.

Competition and profit incentives have often demonstrated faster and cheaper results, so we want to take advantage of them. If there is money to be made, there is a vast pool of capital available beyond agency budgets. The $386 billion Global Space Economy (pdf file) in 2021 was already mostly commercial activity, and 16.5 times NASA's budget.

The original 1982 Version of the seed factory idea was intended to enable large space projects by production in space. But the laws of nature and how technologies work are the same everywhere. If networks of exponentially improving and multiplying systems can work in space, they will work on Earth too. The operating environments, local raw materials, and energy sources may differ by location, but the underlying principles are the same.

The early versions of seed factories would most likely be built in higher income areas. These are the easiest places to start because equipment, materials, and energy sources are readily available, as are people who know how to work with them. Self-built and self-owned production can supplement or replace conventional work for hire. Such jobs have always been at risk from economic and business changes. In the future they may be permanently replaced by the same kinds of advanced technologies seed factories can use.

As the owners of production capacity, people can more securely meet their basic needs. They get the benefit of the output regardless of how much labor is replaced by technology. Self-improving systems can grow to mostly copy themselves, so they would become low cost to build. They can also become highly automated and use renewable energy, making them low cost to operate.

The growing network of productive systems can then be extended to lower income areas on Earth. This allows bypassing fossil fuel development and the problems it creates, while gaining the comforts, health, and safety found in higher income areas. The systems can be further extended to difficult and extreme locations on Earth that are currently unused or barely used. This would lessen scarcity of raw materials, further lowering cost of operation. These expansions and upgrades should be done with planning and care to prevent new environmental side-effects.

Although we describe a progression from easier to harder locations, a given type of location does not have to be completely developed before starting the next category. Rather, their starting points are staggered in order of difficulty, and their development then continues in parallel.

- Goal 2 - Benefits from Space

Economic and environmental reasons are enough reason to build self-improving systems on Earth. Once there is enough experience with them, they can then be used in a series of locations in space. There are several reasons for this:

- Access to materials on Earth is limited vertically because temperatures and pressure increase with depth.

- Solar energy in nearby space averages 7 times more than the Earth's surface because there is no night, weather, or atmospheric absorption.

- Different and much larger amounts of materials are accessible, which can be used without affecting the Earth's environment.

- There are a variety of risks to civilization on Earth, both natural and self-created. Some of them can be reduced by projects in and expansion into space.

So our second goal is to make use of space to bring benefits to Earth, and later extend civilization and the biosphere into the space environment.

Space projects would logically start with easier and nearby locations, then move to farther and more difficult ones in sequence. Developing a new location begins with imports of equipment from Earth or previous locations. Core production and resource extraction is built up, then expands to other kinds of industry. Later deliveries of materials, products, and services helps support operations.

Remote control is feasible when distances are short, or command-response times can be long. But in other cases some people are likely needed on-location to set up and maintain equipment. Suitable locations can build up habitats beyond this for other reasons. Once built up enough, an existing location, along with previous ones, can serve as staging points for the next one, supplying transportation, starter sets, and other items as needed.

Space locations vary in environment, raw materials, and energy resources. So a trade network among them and the rest of civilization makes sense, just like it does on Earth. Each location takes advantage of local conditions to do what it can do best, and trade with others as needed. Through trade, locations can become economically self-supporting and not a cost sink for society.

- Program Advantages

Our new approach has a number of advantages:

- It addresses the frequent criticism of space programs that there are problems here on Earth that need solving. So we place solving economic and environmental problems first, ahead of large space projects.

- Self-improving and highly automated production lowers the cost of rocket factories and launch sites. It also lowers how much you need to launch by using local space resources. The combined result is much cheaper space projects. Activities that are currently uneconomic can become viable.

- In terms of science and exploration, access to the whole Solar System is better than just the Moon and Mars, as interesting as they may be. Locations develop their local resources, so they can sustain long-term operations, rather than being limited to short term missions and single landing sites.

- It is much safer than isolated missions. A network of many locations can keep backup supplies and equipment available, and they can be delivered more quickly. Automated and remote controlled transports can deliver supplies and equipment before the first people arrive, and regularly afterwards, providing a buffer against problems.

- Lower production and transport costs means more robust designs can be used. Current space systems minimize weight to save on launch from Earth. Robust designs will have better safety margins, lowering crew risk. Bulk mined materials, either in raw form or as end products, can provide radiation shielding during long missions. Production capacity at the destination, such as the Martian surface, enables making spare parts and replacement supplies on the spot, bypassing long delivery times from Earth.

3.1 - Program Sequence

[edit | edit source]

Our program concept is organized into a number of phases and smaller individual projects. There are several reasons for this:

- The phases have different scales of operation, or use locations with different operating environments, raw materials, and energy resources. They will need different designs suited to them.

- We intend each phase to economically justify itself, and provide revenue and benefits to support later ones. It would take too much funding for such a large program otherwise.

- New technologies need more development before using them for seed factories, makernets, and various space projects. This will not happen all at once. Splitting up the research and development across phases and projects is more manageable.

- We can lay out a long term program now, but we don't know what new technologies will be invented in the future, or when. Later phases can be identified for guidance and direction, but it makes sense to concentrate on the early ones for now. Details of later phases can be left flexible until their time approaches.

In general, phases don't end, but rather build on previous ones and operate in parallel once started (Figure 3.1-1). For example, mature industrial factories will continue to operate once new locations are set up elsewhere. The phases have a logical sequence, where later steps generally depend on earlier ones. We have identified seven main ones numbered 0 to 6, shown in different colors, with a number of sub-phases indicated by an added letter (4A, 4B, 4C, ...).

Figure 3.1-2 diagrams the logical relationship of phases. It does not show all their relationships, since that would make the diagram too complicated to read. Their general order is from easier to harder, and from local to more distant. Each phase typically involves multiple projects and locations. For example Phase 5B - Mars Surface Locations, would eventually include many projects across the planet. Most locations will evolve across time by expansion and upgrade. The phases are summarized in the next two headings (3.2 and 3.3), and then in more detail in sections 4 through 9.

3.2 - Phases 0 to 3: Earth Locations

[edit | edit source]

Our program in the broadest sense changes the goal from specific destinations, like a mission to Mars, to improving and extending civilization and the biosphere throughout the Solar System and beyond. We start with our own planet first, because there are large and immediate needs here. So the first four phases apply to Earth.

Much of human civilization is unevenly developed and unsustainable, and the vast majority of people will live here for many decades. Starting on Earth allows getting experience with technologies that will later be used in space. It is easier and less expensive to apply them here first, and they can produce economic benefits to sustain themselves.

This program would widen participation from the U.S. national space program, or a joint effort of several national programs, to all of civilization. The NASA budget is about 0.025% of gross world product, and only part of that is devoted to exploration and science beyond Earth. Being more inclusive increases the available inputs for projects, and makes faster progress in the end. The first four phases are:

- Phase 0: Research and Development - The first major phase performs necessary research and development (R&D) for production technologies to be used on Earth, later adaptions to space, and ones used only in space. It also develops transport, habitation, and service technologies as needed for the particular conditions of different locations. The R&D work is spread out in time according to which phases, locations, and projects particular designs are needed for. Some later R&D, such as testing hardware in the operating environment, would occur in space.

- Phase 1: Starter Locations & Network - This phase builds the first sets of seed factory equipment and begins the self-improvement process. Phase 1 equipment can start small, such as home and hobby use, which makes it affordable. Individual equipment items or small groups of them can be located at home or shared work spaces. A network of people directly or electronically coordinate their work to make items for each other, build new network nodes, and start to accumulate larger shared items. New locations may start with less than full starter sets, and build up to making internal improvements. Phase 1 locations are typically in developed and populated areas with access to the materials, energy sources, and equipment needed.

- Phase 2: Distributed and Industrial Locations - One of the ways a seed factory can grow is to use existing machines to make parts for larger machines. This leads from home and hobby size, to small business, commercial, and industrial scale equipment and locations. At smaller scales it is reasonable to gather the full range of equipment and people in one place, and make a wide range of products. At larger scales, the equipment and their operators tend to become more distributed and specialized, and serve larger markets. But they can still coordinate on projects and products.

- Phase 3: Difficult and Extreme Locations - This phase begins extending life and civilization to the parts of the Earth where there is very little or none today. They are unoccupied partly because the environment conditions are more difficult. Self-improving production allows operating affordably in such places. New systems would be set up and grow serially from moderate to difficult and more extreme environments. Technologies like automation and remote control allows machines to operate where it is not feasible for people to stay.

- A major direction for expansion is vertically, to access additional resources and physical space. This goes beyond the fairly thin current layer of activity near the Earth's surface. We can expand the total active area by 7.4 times, but height can be increased hundreds or thousands of meters both up and down. This enables many times more usable volume and materials.

3.3 - Phases 4-6: Space Locations

[edit | edit source]

The later parts of our program involve developing and using space to benefit Earth. It would be based on experience gained in the earlier phases with self-improving systems which can make more such systems. It is also based on the larger production capacity developed in Phases 2 and 3. This capacity enables building transport systems like rocket factories and launch sites, and plus equipment and starter sets to be used at the new locations. The experience in working in remote and hostile environments in Phase 3 can also be applied to the remote and hostile environments of space.

At a civilization level this accesses the much larger physical space, energy, and material resources beyond Earth. Some heavy industry can eventually be moved to space locations, protecting the Earth's environment. It can also decrease societal risks by, for example, diverting hazardous asteroids, or filter parts of the solar spectrum to reduce overheating the planet.

As in the earlier phases, we propose a step-by-step approach: extracting local resources, building up core production, diversifying industries, then sending starter sets to the next locations. Locations become physically and economically self-supporting, allowing moving forward to new ones. The three later main phases are:

- Phase 4: Orbital Locations - Locations in this phase share being in orbit around Earth, or in open space between large bodies. This is in contrast to the the surface or closely bound bound orbits around those bodies. The sub-phases progress from lower to higher Earth orbits, then in distance from the Sun from closer to more distant.

- The main local raw materials are from asteroids and other small bodies, but we can import additional material from Earth, the Moon, and other places. We can also mine a limited amount of the Earth's upper atmosphere and the "debris belt" of discarded space hardware. Solar energy is abundantly available in the open spaces near the Sun, but other solutions become more important in the farther areas.

- Phase 5: Planetary System Locations - These locations are orbits tied by gravity to the Moon, major planets, and their larger moons, or on their respective surfaces. The sub-phases are by distance starting with the Moon, then to the inner and outer planets. Although orbital and planetary locations share features like vacuum or atmospheres we can't breath, they differ in having significant gravity wells or surface gravity, and in having night or time in shadow from the Sun. These differences require different designs, so we place them in a separate phase. Mars is part of this phase, but has long-term and larger scale exploration and development, rather than a few short missions.

- Phase 6: Interstellar Locations - The last major phase of extending life and civilization includes the space between stars and locations bound to other stars. This is mostly speculative right now because it is far away in time. A lot new technology will likely be needed, and what will already be developed by then is unkown. We see no reason to stop just because the edge of our Solar System is reached. For now, technical feasibility limits how far projects can go. But that may change in the future, so we include this final phase as a place-holder, and to provide a direction to plan for.

4.0 - Seed Factory Technology

[edit | edit source]

Our program leans heavily on the idea of self-improving production from starter sets (seed factories), so it deserves some details here. More on the subject can be found in Volume I, and information about Our Project, which is attempting to develop the technology.

Tools and Growth - Humans have always been able to use tools to make more tools. This goes as far back as the Paleolithic, 2.6 million years ago, when hammerstones were used to flake other stones to produce an assortment of tools. In modern times we use metal-cutting Machine Tools to make parts for more machine tools, plus all the other kinds of machines used to make other products.

What is new about seed factories are starter sets purposely designed to make parts for more equipment to improve the set. This can include supplying its own energy and raw materials to operate. There are several ways to improve:

- Replication - making copies of existing parts and equipment,

- Diversification - making parts for new equipment not in the current set,

- Quality - making items stronger, more accurate, or from different materials, and

- Scaling - making different size parts (usually larger) than the current ones.

A relatively small starter set can then grow to produce a wide range and large quantity of products. This can include parts for new starter sets. A starter set may not be able to copy most of its own parts at first, because it lacks the right equipment. After following a planned series of upgrades, though, it can gain the ability to reproduce the original set.

This approach substitutes information, like plans and instructions, for some part of a mature and more capable factory. On Earth this reduces the cost to get started. For space projects it reduces the starting weight and size, making delivery to distant places easier. With modern technology, the information can be stored and transmitted efficiently, and Smart Tools (software, robots, etc.) can do much of the work. However, growing from a starter set will take more time than immediately building a finished factory.

- Self-Replication and Distributed Production

A seed factory is not the same as a Self-Replicating Machine. First, a number of different materials and production processes are needed to make modern equipment. These are best carried out by separate tools and machines designed for each task. For large-scale production the set of equipment will be closer to commercial building size, and better described as a factory than a single machine.

Second, a starter set can be much smaller and simpler than the mature factory. We think of it as the seed from which a factory grows. But a plant seed is not the same as the mature plant, so this is not direct replication in the sense of making an exact copy. If a mature factory can produce new starter sets, it is indirect replication by a cycle of growth and then making copies. This is more like plants and animals reproducing by way of smaller and simpler offspring.

Third, starter sets and the mature factories are not generally able to make everything they need by themselves. At first they will lack all the right equipment. Even when mature there will likely be items too hard to make, or too rare locally. Those need to be supplied from elsewhere. Since they cannot do it all by themselves, they are not fully self-replicating.

Traditional factories and workshops had to bring the equipment and people to one place, because it was the only way to coordinate the work. With modern computers, software, and communications this is no longer required. Equipment in different places can work together, and people can operate them remotely. So a modern view of factory capacity is the ability to make things on a regular basis. The people and equipment may be in one place for efficiency, but they don't have to be - they can be partly or entirely distributed. What's important is they can work together to make desired products.

- Operations and Functions

Production in general involves a number of processes. A seed factory may not do all of them at the start, but they can be added in steps as it upgrades. They include:

- Control of operations - collecting data and sending instructions to the various people and equipment.

- Supply power - this includes electricity, thermal heating, and other sources.

- Extract materials - mining and harvesting raw materials.

- Process materials - converting raw materials to usable inventory.

- Fabricate parts - use inventory stock to produce finished parts.

- Storage and protection - house inventory in various stages of production, plus protect equipment and inventory from local conditions when needed.

- Assemble elements - combine finished parts and materials to produce completed products.

- Grow organics - such as food and timber. These can grow on their own given the right conditions, making it different from other kinds of production.

Most production flows need materials and energy to work with, in addition to tools and machines. In developed areas these can come from outside sources. In less- or undeveloped areas, this may be difficult. Even in developed areas it may be more economic to self-supply. Production systems can start with or build their own mining and processing equipment for materials. They can also start with or build energy sources, such as wind turbines and solar farms.

Once operating, production generally uses up supplies like lubricants and drill bits, and needs replacements for parts that wear out. These can either be part of the starter set inventory, or supplied from outside as needed. Over time, a growing system can start to make these items for itself. In order to keep growing and improving, a given system has to make or import items faster than old ones wear out. It also needs enough supplies of energy, materials, parts, and other items it can't make.

We don't expect to reach 100% self-sufficiency. Some items will come from other places, in exchange for surplus products and services supplied to others. We also don't expect fully automated production at current levels of industrial technology. Some people will be needed to use the equipment and do tasks only people can do. Those people can be physically present, or in some cases control equipment remotely.

5.0 - Phase 0: Research and Development (R&D)

[edit | edit source]

The rest of this report describes our program phases and sub-phases in more detail. It does not cover detailed plans and hardware designs both for length and because they haven't been defined yet. We also can't claim this is the best possible program. We present it as a possible path that leverages self-improving production methods. Much more work is needed on this idea, and we invite other people to help. Where next steps have been identified, we note them here, in our two volumes on seed factories and space systems, and our other documents.

This first R&D phase is numbered zero because it is preparation to make the later phases possible. The sub-phases would be numbered according to the later phases the work applies to. So sub-phase 0.1 would be R&D work that applies to Phase 1: Starter Locations.

- R&D Goals

Our program needs research and development first because we are attempting a new way to organize projects using starter sets and self-improvement. This will need some new equipment and processes for particular environments, especially those in space. So the goal of this phase is to supply ready-to-use technology and designs. Since R&D is the first program phase, it can't evolve from previous ones. Instead it must start with existing items like buildings, tools, machines, design methods, and skills.

Developing new locations is not the main purpose of this phase, like it is for later ones. Places like offices, industrial space, and test areas will be needed for the R&D work, but can start with existing ones. Testing for unique environments may be easier to do in those environments than building simulators. So some later R&D work may move to difficult locations on Earth, or to locations in space.

- Production by R&D Phase

Despite not being the main goal, some production will happen in the course of setting up R&D locations, testing new equipment designs, and figuring out the best operating flows. But these are secondary to the main goal to provide usable designs and processes for later phases to use.

Some of the equipment built for testing may be kept and used internally afterwards. This would help expand and upgrade the R&D locations themselves, and serve as a demonstration of the self-improvement process. Other finished equipment, products, and services generated during R&D can get sold or traded to fund further R&D work. Feedback from such items can help improve the designs.

Final designs should have a long operating life if they are to be useful. So earlier prototypes should last longer than the time needed to test them. Ones with remaining useful lives can be delivered to other locations for later phases and projects. Lastly, the R&D phase may produce some final versions of starter set equipment. These can be used directly in later phases.

- Sharing Our Results

We want our work to have the most benefit for the most people. We plan to open-source the designs, so that anyone can use and improve on them. Individual machines, factories, and the products they produce, would be separately owned, either privately or institutionally.

The R&D Phase may develop new methods and technology to use for itself in the course of working towards later phase designs. We would also make such new developments available for others to use. An example is full resource accounting, which tracks all the inputs and outputs of a system the way financial accounting tracks money. In order for projects to be functional and sustainable, they should account for everything, including scarce resources and all process wastes. If possible they should be recyclable or usable elsewhere, but you can't do that if you don't identify and track them.

- R&D Tasks and Projects

The R&D work is divided up according to the later phases and projects that need it. Items used by multiple phases are assigned to the first one they are needed for. Later phases start at different times. So the R&D work for each one is started far enough ahead that it is ready when needed.

New designs and technology are likely needed even for the last phase. So we expect R&D work will continue for the whole life of our program. In addition to internal R&D work, we expect technology to make progress outside our program. So part of the R&D phase is staying current with outside developments so improved designs and methods can be developed later. The growth of locations, and unique conditions found there, may require design updates, new hardware models, and customization. Lastly, we expect feedback from using the items in later phases and suggestions for improvements. All of these are reasons to continue the R&D process.

The R&D work is also grouped into individual projects according to the technologies being developed or type of end use. So far we have started the Seed Factory Project to develop the basic ideas for self-improving systems, and started working on what is needed for Phase 1 locations and networks.

Future R&D project examples are ocean mining platforms or interplanetary tugs. Such systems would be used in later phases, so we have not identified specific ones to start yet. There is a lot of science and technology work happening elsewhere in civilization. We do not expect to duplicate that work, but use their results where it makes sense, and contribute back our own results to the general fund of knowledge.

6.0 - Moderate Locations

[edit | edit source]

Once the R&D phase starts providing plans, designs, and technology, the core self-improvement methods stay the same in all later phases. But equipment sets must be adapted to local environments, material and energy resources, and available people and their skills. Finished products and services also need to be adapted for local and export use. So our program concept has multiple later phases to account for all these differences.

Phases 1 and 2 are for the easiest environment conditions, which we call "Moderate". This includes temperatures, water supply, and a number of others environment conditions. We list them in section 7.1 which covers conditions that are more difficult. Moderate ones are the kinds of places where most people currently live. Among them are locations with significant population and physical development, such as around cities. These locations have enough people, supply sources, and transportation to get started. So they are the easiest ones to build the first projects in. The three phases/sub-phases for these areas are mainly distinguished by scale of operation. They are 1:Starter, 2A: Distributed, and 2B: Industrial.

6.1 - Phase 1: Starter Locations and Network

[edit | edit source]

- Goals

The main goals of this phase are (1) provide products and services at the personal and community level, (2) develop experience with starter sets and self-improvement, and (3) develop networks among local sites and different locations. Network members can trade physical items as needed, and coordinate their work on larger or more complicated projects, despite being in different places.

Networks would be used in all later phases. This is because (1) locations vary in the material and energy sources available. (2) Individuals and groups have variable skills and interests. They also may not want to travel too far to work on projects. (3) Physical space, utilities, safety, and local rules may limit the work done at a particular site.

- Starting Points

Projects in general need tools, resources, energy, and knowledge to complete, or "TREK" for short. Early projects won't have the benefit of a lot of finished R&D work. To start with they can use already developed tools and machines, existing sources of materials and parts, available electric power and fuels, and the many books, online videos, and other information sources on how to do what is needed.

An early project example is setting up for a hobby or home improvement. Such projects don't have to be completed all at once. They can be started with minimal equipment for the first steps, and gradually add more as skills accumulate. Eventually an owner can start building custom items like a work table or storage for themselves. If they can find other people interested in similar projects they can share knowledge, trade items, and help each other when extra people are needed. Like other parts of our program, people's skills and the equipment they work with are not intended to reach a static end point, but to grow and develop over time. So self-education, training, and practice are encouraged.

Equipment for this phase starts at the hobby and home use level, for personal and local community products and services. Their duty cycle (percentage of time in operation) is less than full time, and the equipment is smaller and less expensive. This puts the equipment in reach of ordinary people or small groups. Groups of people can afford a number of these smaller items. They can be housed in space they already have, or can build or rent without too much difficulty.

Equipment may be distributed at people's homes, or grouped into clusters on one property, such as a Community Workshop or small scale production cooperative. Individual sites may be limited in size and cost, but the network as a whole is intended to grow and improve.

- Later Improvements

Improvements can come new R&D work. personal experience, more copies existing items, scaling to larger (and sometimes smaller) sizes, and purchases funded from sales. As the network expands and upgrades itself, it can produce more items internally for further upgrades, and more products for network use or to sell. Network production can be logically grouped into (1) tools and machines intended to make more tools and machines, (2) items intended for production but not for making more equipment, such as a sawmill or greenhouse, and (3) finished products to be used, traded, or sold, like furniture and food.

The R&D phase would gradually develop plans, designs, and instructions for starter sets, upgrade paths, and custom equipment. These would be shared as information, and can start to be provided as packaged sets. Later projects can then start self-improving faster. A trading network can grow as more sites in more locations are built.

Examples of future R&D-developed equipment include a 1x2 meter bridge mill, with replaceable heads and bits so it can perform different tasks, and a 15 kW solar furnace with replaceable focus targets. The furnace can directly heat items in a crucible, or generate steam for an electric generator. Such starter set equipment is designed for flexibility, rather than maximum efficiency and speed. That way a smaller starter set can be used for a variety of tasks at lower cost. Later equipment, built with the help of the starter set, can be dedicated to single tasks with higher efficiency and performance. Starter equipment may be supplied finished and ready to operate, as kits with some level of assembly and supplies needed, or purely as plans and instructions.

6.2 - Phase 2A: Distributed Locations

[edit | edit source]

- Goals

The goals of this phase are (1) increased scale of sites and locations, and (2) relief from job insecurity and displacement by automation.

- Evolution

Phase 1 locations in general would accumulate skills and equipment. Some sites will move beyond hobby and home use, towards more regular small business and commercial activity. This involves part or full time operation, and selling more products outside the self-improvement network. The larger scale and more intense uses will need different equipment sets.

When running a business, speed and efficiency become more important, so equipment is chosen or built to do particular tasks well. This results in a larger collection of more specialized equipment. Skills and training also become more specialized and take longer to learn. Particular sites will tend to do a few things well, and trade for other things they need. A comprehensive large node (general purpose workshop or factory) that does many kinds of work is still possible in this phase, but less common. So working sites will tend to be distributed in multiple places.

Business and commercial scale operation is not limited to production only, but can also serve the full range of habitation, transport, and service industries. For example, a restaurant is a service business, but it needs a building, furniture, and kitchen equipment first. So the logical progression is from core equipment to make more equipment, then finished products like building materials and furniture, and finally industries that don't produce items, but use them to operate.

- Ownership

In the current economic system, separation of ownership and labor results in the problem of job insecurity. The owners of a for-profit business have the incentive to remove workers as soon as possible to save on labor costs. The removal may be due to lower production and sales, or changes in business methods and technology that need less labor or different skills.

When a person or group has built and expanded their own equipment and business, the owners and workers are the same people. They don't have the same incentive to remove themselves. To the extent they make items for their own use, production would remain constant. If outside sales decrease, they own the equipment to build and start doing something else to make up the difference. Automation is a threat to conventional jobs by needing less labor. But owners who use the same automation for themselves are not threatened with unemployment. Rather they just work less time or more efficiently.

By diversifying into different industries, self-owned production can integrate with the rest of civilization and be self-supporting. New network members can become owners by first building or buying into a share of core production. They can then use that production to make or trade for what's needed in other industries. Alternately they can start out working for others in their chosen industry, and buy or trade for production shares. Either way they have more security as owners.

6.3 - Phase 2B: Industrial Locations

[edit | edit source]

- Goals

The main goal of this phase is to reach the most efficient production capacity by additional growth in scale and specialization. Industrial locations are in the same kind of developed areas and moderate environments as Phase 2A Distributed Locations, so we group them together under Phase 2.

- Growth and Specialization

Industrial nodes can evolve from distributed small business or commercial nodes by continuing self-improvement and growth. They can also be built as new nodes of the final size, where the equipment is supplied by other parts of the network. In that case, supplying the larger equipment and space to house them will likely need outside capital, because individuals or a small group typically won't have enough funds. Gradual evolution from a smaller size by self-production would not require as much, or any, outside funding.

Larger work spaces with larger input and output flows will tend to limit industrial locations to fewer products. For example, if you are processing scrap metal on an industrial scale into new metal stock, it helps to be near a rail line to transport the scrap and the finished metal. The more products, factory space, and specialized needs you have, the less likely you will find one big location that can satisfy all of them.

The larger production scale means more outside customers for the products, or larger scale customers. The market area for a site will likely reach beyond a single location, to a region or even world-wide. Since outputs are sold to a wide range of customers at greater distances, transport capacity becomes more important in this phase.

A narrow product range and large scale markets means demand can be more variable from general economic circumstances or competition. Distributed finance and ownership makes sense in this case. Demand may be low for a particular product, but may be high for something else. In a distributed portfolio these tend to average out. Owners can then reassign their labor and equipment as needed to meet the higher demand products.

The overall network has a high capacity to recycle and self-produce what it needs. So modifying equipment to meet changing needs is easier to do. This is a somewhat different business model than investors and workers, with managers in between. It more a network of active owner-operators who can change the mix of what they own and what they produce as needed.

Like distributed locations, industrial ones can serve the full range of industry types. A combination of industrial, distributed, and individual scale industries can meet most of the needs that people have. If they own their own equipment, or shares in them, because they collectively built and grew them themselves, those needs are met securely, despite higher levels of automation.

7.0 - Other Earth Locations

[edit | edit source]

- Goal

The main goal of this phase is a better quality of life through sustainable development. The Earth's population is growing, and most people want a better lifestyle. This needs more physical resources and energy. But the Earth is already being stressed by human impact on the environment, and future growth will only increase the stress.

- Method

One way out of this dilemma is to produce abundant renewable energy with self-improving systems. These systems make more of themselves exponentially, including more power sources. Renewable energy will have much less impact on the planet's heat balance. Large amounts of energy allow increased reprocessing of wastes, and extraction from lower grade ores or even common rock and ocean water. Rapid expansion brings material goods to the rest of the world faster. Self-production and automation lowers the relative costs of products, energy, and materials.

- New Locations

Increased supply of raw materials and energy will likely need access to more difficult and remote locations. So Phase 3 covers working in areas that are thinly or completely uninhabited, or that have difficult or extreme local environments. New designs and processes will be needed for such areas. So a new program phase with added R&D is started.

Harder conditions are a matter of degree, rather than absolutes with a clear dividing line. Sections 7.1 and 7.2 list the ones we have identified. We define the "normal" (moderate) range as those where the middle 90% of of people live. Difficult and extreme conditions are then significantly above or below the moderate range.

If at least one of the eleven parameters is well beyond the moderate range, then the location is assigned to the difficult category. Extreme locations are even farther from moderate, and can be hostile to people living and working there. More remote-control and automated operations will tend to be used, instead of trying to build controlled environments for people.

We want to preserve the Earth's total environment, and the parts that are still in a natural state. So developing the difficult and extreme locations must consider sustainability, renewable energy, and environmental impact. An example would be building offshore fisheries to replace wild fish catches. The latter are putting a strain on the ocean food chain, so it is desirable to minimize that impact. But the fisheries must consider all their inputs and outputs in a total system approach to avoid unintended side-effects.

The mechanics of building in these locations is somewhat different than previous phases. These areas are less populated, with fewer supply sources and utilities available. So growing from a minimal set of tools and machines is harder to do. Instead, more finished equipment is sent from previous locations to start basic functions like mining and producing energy. A set of production equipment then uses these resources, plus some level of imported supplies, to increase capacity.

That capacity then supplies products and services are for local use. Surplus output is traded with the rest of civilization to make the locations self-supporting economically. Once built up, a location can also contribute to starting additional ones. The experience gained in working in difficult or extreme conditions, working remotely, and building up resource extraction and production in such places will be useful for later phases beyond Earth.

7.1 - Phase 3A: Difficult Earth Locations

[edit | edit source]

We define moderate conditions as those where the middle 90% of the Earth's population lives, with 5% at the upper or lower ends for a given parameter. This definition is somewhat arbitrary, but we think reasonable from a design standpoint. The "Difficult" environments are then those that are at least 10% beyond the moderate range in at least one parameter. 10% is measured either linearly or as a logarithmic factor, depending how wide the normal range is. The parameters and moderate and difficult ranges are:

Temperature - This is measured by winter average daily lows and summer average daily highs. The moderate range is 260-310K (-13 to 37C). A given location is likely to exceed either the high or low limit, but not both. The difficult range is therefore below 255K (-18C) or above 315K (42C). Examples of difficult temperatures include Chelyabinsk, Russia, where average winter lows are -19C, and Death Valley, California, where summer highs are up to 47C. The lower limit ie more likely to be reached at high altitudes and latitudes. The high limit is more likely to be reached deep underground, because the Earth's internal temperature rises 25 Kelvin/Celsius on average per kilometer of depth.

Water Supply - This is measured by fresh water supply in meters or tons/m^2 per year from rain, rivers, snow, ice, moisture condensation and freshwater aquifers. Salty surface water and aquifers are not included, as they aren't drinkable without desalination. Aquifers are limited to natural replenishment rates, as they are not sustainable if drawn from faster. The moderate range is 0.25 to 2.5 meters/year. Since this is a large range, we use a logarithmic scale, and define difficult as 26% below or above the moderate limits, or <0.185 and >3.15 meters/year. The world's drier deserts fall below the 18.5 cm rainfall level, and places like the east coast of Nicaragua exceed the 315 cm upper limit on rainfall. Too much water is difficult because it can cause problems like flooding, erosion, and decay.

Atmosphere Pressure - This is measured by average local air pressure in kiloPascals (kPa). For reference, standard sea-level pressure is 101.325 kPa (14.696 psi). The moderate range is assumed to be from 80-100 kPa (near sea-level to 2000 meters altitude) Difficult pressures are below 70kPa (2750 meters altitude) or above 110 kPa (750 meters below sea-level). These correspond to high mountains or plateaus, and deep underground at low altitudes, since the lowest surface elevation is -413 meters. Low pressures and rapid changes in pressure can cause medical problems for people, so pressure-control is needed where people are. Effects on equipment are mostly minor in this range.

Ground Pressure - This is the ground/soil strength at the surface, or surrounding water or rock pressure below the surface, in MegaPascals (MPa). These affect the design of structures, and values that are too low or too high become difficult. For reference, average household floors are designed for 0.275 MPa loads. The moderate range is 0.25 to 2.0 MPa. Difficult conditions are then below 0.19 MPa or above 2.5 MPa. The high limit is reached at ocean depths of 250 meters, and underground at depths of 100 meters in average rock. High surrounding pressures require closed containers to lower them for people, or support structures to prevent collapse. The low limit is reached in open waters (zero strength), fine sand or moist clay (low strengths). Low ground strength requires larger building foundations, or floating construction in the case of open waters

Energy Supply - This is measured by average energy supply from renewable natural sources in W/m^2. Wind and solar are available in most places, and are rapidly renewable. Ocean thermal and geothermal are widely available if you go deep enough, but take long periods to renew once depleted, so we only count their renewal rate, not the stored energy. Sources like hydroelectric or tidal energy are not available everywhere, but counted if they are.

Fossil fuels are not sustainable because of finite supply and the waste products they produce. Biofuels may be produced sustainably. Fuels for nuclear fission and fusion (which is still being developed) are in large enough supply to be considered sustainable but require mining or separation. They can be used to produce energy, but we don't count their contribution to local supply.

Low energy supply is difficult because some is needed for almost every kind of human activity. If it is not available locally, it must be imported by methods like fuel delivery or power lines. High levels of energy supply are not considered difficult. The range of energy flux is roughly 150 to 900 W/m^2 on Earth, so a difficult low value is 125 W/m^2. Any significant depth below the surface is cut off from wind and solar sources, so are likely to be difficult and require energy supplied from elsewhere.

Gravity Level - This is mainly one of the conditions for space environments. On and near the Earth's surface it does not vary by more than 10% unless you are in a centrifuge or accelerating vehicle, so there are no natural places on Earth beyond moderate conditions. Low gravity causes biological problems for people, and may for animals and plants. High gravity is difficult to work in for people, and requires extra structural support for physical items.

Radiation Dose - This is measured by unprotected background radiation in milliSeivert (mSv)/year. Industrial exposure, such as to medical imaging staff, or from mining, using, and disposing of radioactive materials, is not considered an environment condition. But such exposure needs its own designs for safety and shielding. Natural background radiation varies by location, according to altitude, magnetic field, and what materials are in the ground below. In most places on Earth it varies from 1 to 13 mSv/year.

A few places have high radiation levels from concentrations of radioactive elements and their decay products, up to 135 mSv/yr. People have lived in such locations for many generations, with no apparent ill effects. Since adaption may have occurred for long-term residents, we will be conservative and consider high radiation levels a hazard to the general population.

Levels above 17 mSv/year would be considered difficult. Depending on sources, they might require shielding, sealing, or air circulation. Low radiation levels are not considered hazardous, so background levels below 1 mSv/year are not considered difficult. Note that the human body contains some radioactive elements naturally, so there is no zero background level. Even the highest natural radiation levels on Earth are not significant for most equipment designs.

Ping Time - This is the round-trip communication delay to the next nearest 5% of world population, in milliseconds (ms). Long delays create difficulty in voice communications or real-time remote control, and slow down any computer network-based activity. There is no lower limit for this parameter, since short ping times are not a difficult condition.

On or near the Earth's surface we consider ping times above 100 milliseconds to be difficult, as this much delay starts to be noticeable to people. There are few locations that have such high values to reach 5% of the world's people. The 5% value is because you can choose to do tasks like remote control from reasonably nearby, and not from the farthest place on Earth. This parameter becomes more important in space. The speed of light limits operations to within 15,000 km to stay under 100 ms. That only reaches moderately high Earth orbit, and most of space is far beyond that distance.

Travel Time - This is the maximum one-way normal travel time for people, to reach the nearest 5% of other people. Travel time for cargo is assumed to be proportional to that for people. High travel times makes it more difficult and expensive to bring in people with special skills, or necessary parts and materials. Densely populated areas can usually be reached in 5 hours or less. Most of the world's populated areas can be reached within 48 hours, so we set this as the upper limit for moderate (developed) travel. The worst case travel time is 10-20 days for parts of Tibet which lack roads, and ocean locations distant from any airports, requiring ship travel to reach. Very low travel times are not a difficulty, so we set no lower limit for this parameter. We define difficult travel as needing more than 2.5 days.

Stay Time - This is the average stay time per person per location, in years. People stay in the same location if they live and sleep there the majority of the time, and make trips to other locations less than half the time. Short stay times are more difficult because of increased transportation needs and staff turnover. The short times may be caused by a harsh environment, lack of habitation and services, or the location is simply undesirable. It can also be caused by a rapidly growing population lowering the average residence time. In that case, the difficulty is caused by having to rapidly build new habitation and services.

Long stay times are not considered difficult, and their upper limit is the human lifespan. Rapidly growing areas provide the shortest average times on Earth, 7 years if normal turnover is added to growth. Since the upper bound is ~70 years, we will set the difficult limit at 25% below the shortest average, at 5 years. Examples where such low values occur are mining and construction camps in remote locations.

Transport Energy - This is the total energy to reach a location from the nearest 5% of population, by the most efficient method, in MegaJoules per kilogram (MJ/kg). For reference, 3.6 MJ = 1 kiloWatt-hour of electricity. Transport energy includes kinetic, potential, and frictional energy. High transport energy is difficult because of increased need for equipment, and their higher cost of operation.

On Earth, potential and kinetic energy of transport are generally low, and friction dominates. Rail and water transport are currently the most efficient bulk methods, and range from 0.225 to 2.25 MJ/kg between densely and sparsely populated areas. Low transport energy is not considered difficult, but we set values above 2.85 MJ/kg to be. Such values can occur when rail and water transport are not available, and part of the trip must be by less efficient methods. It can also happen when there is a lot of altitude change on the route, increasing frictional losses so as not to exceed speed limits.

Some of these parameters change with time, due to technology and development. For example, parts of Alaska had long travel times when the only available transport was by dog sled. Once small airplanes and a network of landing fields were available, it became less difficult. It may be a specific goal to upgrade a location to less difficult status, but we define it for phases and R&D by the pre-existing conditions that have to be dealt with.

7.2 - Phase 3B: Extreme Earth Locations

[edit | edit source]