Telescope Making/Assembling the Telescope

The Primary Mirror Cell

[edit | edit source]The Secondary Mirror Mount

[edit | edit source]The secondary mirror mount must hold the secondary mirror at the proper position in the tube and in the optical train. It must allow for minor adjustments of both of these positions, and retain the final position without slipping. The mount is actually made of two parts, a mirror mount and a tube position mount. There are just a few considerations to think about ..

- Telescope tube size and shape,

- Secondary mirror size and weight,

- Material available,

- What you want to achieve.

The mirror must be held without tension so that the surface is not distorted, which would impact the image. Hard adhesive products shrink as they cure and squeeze the glass, which in turn distorts the surface. Mechanical attachments, clips, rings, etc. must allow the mirror to "float," because the differing rates of expansion of the different materials can squeeze or bind the glass. When you decide what mirror mount to use you should also consider how that mount will be attached to the tube position part of the assembly, and how it will be adjusted to get proper collimation of the optical train.

One of the oldest secondary mirror mounts is a simple mechanical mount. A short piece of tubing, a bit bigger in its diameter than the minor axis of the secondary, is shaped by cutting one end at a 45 degree angle. Small L-shaped clips are made and screwed or glued to the outside of the tube to retain the mirror. The mirror is placed in the tube and cotton balls are loosly packed in behind it to hold it against the clips. The tube is then capped on the open end to hold the cotton balls in.

The idea is that the mirror just floats in the tube, which takes all of the stress of mounting. The mirror is given its basic orientation, held at the proper angle, by cutting the end of the tube at 45 degrees and holding the mirror against that plane with cotton balls. The mirror and the tube have about the same cross sectional area in the light path so additional obstruction is minimal.

This is a very good mount although it can be a bit difficult to make if you are short on tools. The tubing used can be plastic or metal or cardboard. You want a tube that is a little oversized so it doesn't squeeze the mirror. You could make one of these out of a toilet paper tube and it would function well. The clips could be of thin wood, (popsicle sticks), glued on. The 45 degree angle on the front end should be as accurate as you can get it (find someone with a carpenter's mitre box and use that to cut the tube), but final optical alignment is accomplished with the tube-position part of the mount. An angle that is a bit off is not a big deal. This mount is very good for the large secondary mirrors found in larger scopes.

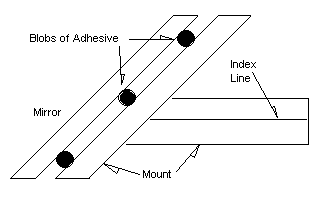

Another type of mount is made from a simple piece of wood or plastic or even metal. Take a dowel, or even a square or rectangular piece of material, that has ends smaller than the secondary mirror. Cut one end at a 45 degree angle. Now you can glue the mirror to the 45 degree face and you are done. Remember that hard adhesives will squeeze the glass as they cure, so use a non-hardening adhesive. Silicon rubber, also called room temperature vulcanizing rubber, RTV for short, will hold the mirror but will not squeeze it as it cures. It also resists temperature changes, so expansion and contraction are not a factor. It is a spongy material and will buffer the mirror from shocks and changes in the mount. You should use three small blobs to form the bond, not one big smooshed-out blob in the middle. Use some toothpicks or small wood skewers to space the mirror away from the mounting surface, so that the glass and the mount are not in direct contact, but are held together by three blobs of soft adhesive.

Another possible adhesive for this mount is double-sided foam tape. Get the thickest core you can get. I use this stuff everywhere on the telescope to mount all sorts of things, so a roll is a handy thing to have.

You must make sure the cut end of the mount is very smooth. Sand it off very smooth, and seal it with a layer of nail polish or epoxy. Now just cut a single piece of the double-sided foam tape, put it in the middle of the mirror-back, and stick it on the cut face of the mount. The foam core provides the same sort of mechanical and thermal buffering that we got with air and rubber and it is much easier to use.

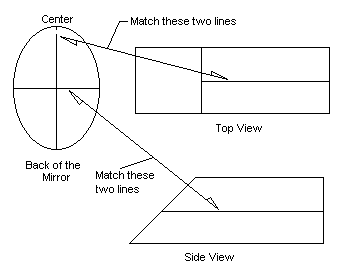

The danger in using an adhesive-based mount lies in not getting the mirror glued on squarely. The mirror must have its minor axis perpendicular to the eyepiece for the minimum amount light obstruction. The simplest way to make sure it is properly lined up on the mount is to make some index marks on the mirror and the mount prior to gluing.

Get a sharp pencil and a ruler. Lay the secondary mirror face down on a piece of paper. Lay the ruler edge along the major axis. Get as close as you can but don't lose sleep over it. Draw the diameter line for the major axis of the mirror on the back of the mirror. Now measure the major axis and divide it in half. Make a mark at the center of the major axis line and use the ruler to draw the diameter line for minor axis through that mark, as in the drawing above. Get as close as you can and try to make the intersection of the lines at the middle of the mirror perpendicular to each other.

Now take the piece of material you are using for a mount and draw a straight line one each side of the wood, as close to the middle of the side as you can. When you glue or tape the secondary to the mount, line up the lines on the mirror with the lines on the mount and you will be close enough.

These simple adhesive mounts will work well for smaller mirrors, the kinds of mirrors we will be using to make a pie pan telescope. Larger mirrors require a better mount and some form of mechanical mount would be best for those mirrors. There is a hybrid of these two forms that can be used for big mirrors.

Make an oval that matches the shape of your secondary mirror. Glue and screw that oval to the mount face, or weld it on if you are using metal. The oval should be made of good solid material. You should line it up using index lines, just as you lined up the secondary in the above procedure. Now glue your secondary mirror to the oval using several small blobs of rubber or several pieces of tape. The mirror is well attached to the oval by the adhesive, and the oval is mechanically attached to the mount assembly. You could add a couple of small clips to the oval to help support the secondary mirror. Remember, the mount should not pinch or squeeze the mirror.

The Tube Position Mount

[edit | edit source]Now that the secondary mirror mount has been made or chosen, we need a way to place it in the telescope tube. The secondary mirror should be mounted in the very middle of the tube to catch the focused image from the primary mirror and turn it towards the eyepiece and focuser. This process is decided more by measuring than anything, but there are some tricks we can use and there are many ways to position the secondary in the tube.

The first step is to measure the telescope tube diameter inside and outside. You can do the math and size the mount accordingly, but I like to draw a full size diagram and work from that. I take a piece of paper at least three or four inches bigger than the outside tube diameter. Draw lines across the paper from corner to corner using a straight edge. Where the lines intersect is the middle of the paper. Now I use a compass to draw a circle as big as the inside diameter of the tube, or a square if I am using a square tube. Now I can play with various ideas for mounting the secondary mirror in the tube. I can get real measurements and understand what I am going to be working on. Lets talk about some mounts.

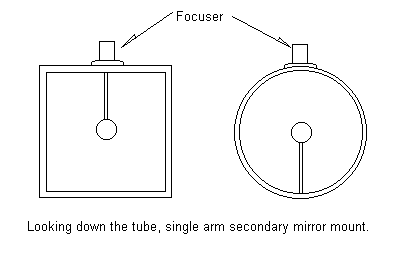

The simplest tube mount is a single arm that supports the secondary mirror mount at the right place in the tube. The arm is usually attached to the tube near the focuser hole, or on the opposite side. This avoids one source of distortion from gravity. In use, the focuser will be on top of the tube; if the mount was on the side, it could flex downward from gravity and make it hard to collimate the telescope.

Single arms are quick and elegant but they have a fatal flaw: they vibrate. That one arm with the weight of the secondary mirror at its end is a pendulum. Bumping the tube will make it vibrate for a while. If you use a thicker material and one that dampens movement, for instance a soft wood, you can minimize the vibration, but it will always be there. My early telescope, "The Long Dog," had a single arm secondary mirror mount. It could be irritating but I did a lot of viewing with that telescope and I never swapped it out for something else.

Attaching the single arm to the secondary mirror mount can also be a challenge. If you use a piece of threaded metal rod, you could bore a hole through the mount and one through the tube wall. Then you could attach and center the secondary with nuts and washers. That is what I used as a single arm on "The Long Dog," and it gave me an infinite adjustment to center the secondary in the tube. Final collimation was accomplished by bending the threaded rod to position the secondary mirror.

If you want to glue the arm on you need to be sure the mirror is in exactly the right place and that will stay there while the glue dries.

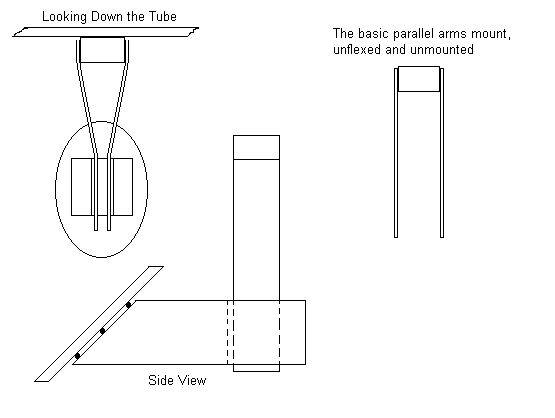

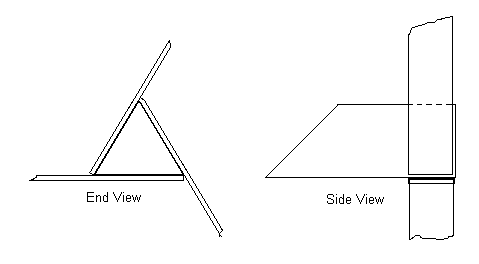

A variation of the single arm is a design using thin parallel strips, closely mounted and flexed together to form the single arm. This is basically a triangular truss and cancels all vibration. Collimation is achieved by moving the secondary mount on the truss. The friction of the material holds the alignment, or you can glue it up and fix the position pemanently. See the drawing below for details.

You can make this assembly out of popsicle sticks, clothes pins, or just thin scraps of wood. It could also be made from stiff plastic. This is the mount I use in my pie pan telescopes. It is also in my rock scope.

Really the only consideration is that the material used be flexible enough to not break when it is bent through the secondary mirror mount. You should cut out the slot on the mirror mount prior to mounting the mirror on it. The slot should only be as wide as three or four pieces of the strip material you are using. There is no need to go wider at the top than 3/4 of an inch. A shorter set of arms would be better served by an even narrower top end, say 1/2 inch or so. The best thing to do is hold the assembly in your fingers and squeeze the ends of the strips to see how much tension there is and adjust the separation accordingly. You want enough friction to hold the secondary in place under its own weight.

Three-arm mounts are an old and reliable standard. The arms are cut to the length necessary to hold the secondary in the middle of the tube. They are then mounted equidistant around the secondary mirror mount so that by their very length they center the mirror in the telescope tube. John Dobson has used the three-arm design forever it seems. Once he has the assembly put together he puts it in the telescope tube, collimates the scope, and then glues it in place. He recommends, and I agree, that the arms should not be round or square, but flat and thin, with the thin edge placed towards the tube opening. This gives a better strength to the tube mount.

You can make this mount quite easily in wood. Make the mirror mount out of a piece of wood cut to the shape of an equilateral triangle. (Think of a long prism.) Now cut the 45-degree end for the mirror to mount on. Make the three arms and glue and screw or nail them to the end opposite where the mirror will attach. Make sure they are perpendicular to the mirror mount. I cut the arms over-long, then size them for length by centering the assembly on my full-scale drawing and marking the arms there. Once it is assembled and the glue has dried, attach the secondary mirror and put the assembly in the telescope tube.

John Dobson does this mount using a dowel. He cuts a groove in the side of the dowel at 120-degree intervals and then glues each arm into place in its groove.

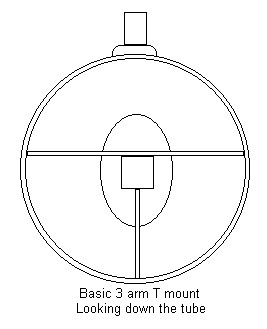

A variation on the three-arm mount is a T-mount having a single arm that goes all the way across the telescope tube, and a second short arm that runs from the mirror mount to the wall of the tube. These are a great design as they are simple to do. They combine well with a square mirror mount.

You can add another arm and do a four arm mount. These are very stable and work well in round or square tubes. The more arms you use, the more complex the mounting becomes, and the more obstructions there are in the light path. But it all comes down to the same batch of considerations:

- Telescope tube size and shape,

- Secondary mirror size and weight,

- Material available,

- What you want to achieve.

Make a decision based on these considerations. Make a complete mirror mount first, including arms, and then attach the secondary mirror. Finally, mount the assembly in the telescope tube.