Chapter 2.1 - Self Improvement and Seed Factories

In Chapter 2.0 we looked at processes of expansion, replication, and self-improvement in nature and in human history. This history has led to some current problems, which we would like solve in better ways than previous approaches. We would also like to avoid future problems and help people build a better life for themselves.

Problems like a worsening environment are world-wide, and can only be solved on a large scale. Stored information can be easily copied by modern technology. Adding physical systems that self-improve, grow, and copy themselves could provide the needed scale for large problems.

We can avoid new problems and side effects by considering the whole of large and complex systems in advance. This includes all their interactions with the surrounding world over their entire life-cycle, from design to disposal. Every part of such systems have to be considered in terms of external inputs and outputs - where they come from and where they go. We also have to consider how the parts of a system affect each other.

Our basic approach in these books is then to take processes of change, like expansion, replication, self-improvement, and evolution, and combine them with "whole systems thinking". In that way we can plan and optimize the changes to avoid side effects and new problems. Note that small projects, like building a workbench for personal use, aren't big or complex enough to need a systems approach. It is enough to source the materials and dispose of wastes responsibly.

This chapter (2.1) looks at new kinds of systems that are intentionally designed to improve, grow, and make copies over time. In particular we will present the idea of a "seed factory" - a starter set that can grow into a mature factory with desired outputs. The following chapters will look at design features for such systems, and the process for developing the whole of complex systems. Chapters 5 through 8 and Volume II provide a series of design examples using this approach. We think work on these kinds of systems should start now because the existing and future problems they can solve are worth fixing. Developing and refining the systems will still take time, but waiting to start just means it will take longer to finish.

1.0 - A New Approach to Old Problems

[edit | edit source]

We saw in Chapter 2.0 that expansion, replication, and tool use have a long history in nature and among our ancestors. We continue to use them today to grow our food and make all the artifacts of civilization. It seems obvious to use these same processes, our tools, and the economic and legal structures which have led to our current problems as part of the solutions to those very problems:

- From biology we can draw on the ideas of growth, replication, storing and modifying instructions, evolution, and ecosystems with energy and material flows.

- From technology we can draw on already accumulated knowledge, how to copy and distribute it, and a history of adding new tools, and the making of better tools using the ones we already have.

- Smart tools and other productivity-improving technologies can displace workers and their jobs. But instead of seeing them as a problem to be fought, we can use them as part of the solution.

Concentrated ownership and unfair terms of trade, backed by the force of governments, are underlying causes of many economic problems. Relative poverty, job insecurity, and regional underdevelopment are some of the consequences.

- We can change ownership structures to cooperative and membership methods to guarantee participation and fair shares. We can build in reserves and backup plans against adverse circumstances. And we can use the abundant material and energy resources around us to avoid future problems and risks.

Combining all these ideas we can create a new approach - one which allows people to help themselves. This kind of approach can still work even in the face of continuing large-scale change in the future.

1.1 - Expansion and Evolution

[edit | edit source]

We know from history that large constructs like cities can expand and evolve over time. But this can happen on a small scale too. For example someone with a home workshop and tools can add to their house or put up a new building for a larger workshop. They can build more workbenches and add tools to improve and evolve the shop. Two of the problems we seek to solve are regional under-development and individual poverty. So starting small and simple, then upgrading over time, is a way to deal with them.

1.2 - Replication

[edit | edit source]

Plants and animals can already replicate themselves exponentially if given the opportunity. We can copy information many times using things like books and computers. People's knowledge and experience can be multiplied by teaching and training of groups at a time. But physical items like houses and machines have not been so easily multiplied. Instead they are made serially - one after another. We can adapt the biological process of replication to non-living things, using the idea of Machine Replication. While fully autonomous self-replication is not yet possible, we can replicate many items by people using existing tools, machines, and automation.

1.3 - Tool Sets

[edit | edit source]

A single tool has a limited range of things we can do with it. A box of tools, or a workshop with many of them, can do a larger variety of tasks. The number of ways you can combine sequences of steps, using different tools, grows much faster than the number of tools you have. A sequence of steps with a desired outcome is called a Process. A process using a large enough set of tools can copy one of its own tools, or make a different one to add to the set. A sufficiently large tool set can be used to copy all of its own members, or make any new tool which we have the knowledge for.

This is in fact how civilization developed from rocks and sticks to what we have today. But the historical growth in quantity and variety of tools, and the things we could make with them, was limited by the knowledge we had at the time. The energy and materials we could use was also limited by our knowledge and tool sets. Today, we can use our increased knowledge to start with better sets of tools and processes for specific tasks. One of those tasks can be to grow, evolve, and replicate the tool set itself.

1.4 - Knowledge, Specialization, and Combining Efforts

[edit | edit source]

Modern society is complex. No single person can acquire all the knowledge and skills to maintain a high standard of living. Buying all the necessary tools and equipment, and enough time to use them all, is also out of reach. Working in groups within a network makes it possible and affordable to live well. The needed knowledge and tools are distributed across a larger number of people. Making many of their own tools and products greatly reduces the costs involved. Through numbers, they can accomplish projects too complicated or large to handle otherwise.

The average person can't build complex devices like automobiles or smartphones, but they can certainly use them. Despite their complexity, the same should be true for smart tools if they are designed properly. If needed, they can come with instructions for installation and tutorials for operation. Training and support from specialists can also be available, the same way they are for phones and autos today.

2.0 - Self-Improving Networks

[edit | edit source]

Our proposed solution to large-scale physical problems is then to combine all the ideas from heading 1.0 above into self-expanding and improving production networks. These networks are built by groups of owner-operators, who bootstrap from smaller and simpler starter sets of tools. They use these tools to make finished items for themselves, for each other, and to supply products and services to other people. They also use them to make better and larger tools to upgrade their capacity. This would eventually grow to include smart tools, and making new starter sets for new groups.

The smart tools work for the owners, so they are not at risk from job insecurity or work displacement to themselves. In this way we can use the same tools that created the problems to solve it. As owners, they still benefit from what their tools can produce, no matter how advanced or automated they become. A mature network could supply all of their basic needs, such as food, shelter, and utilities, and some luxury goods. The more of their needs they can meet within the network, the less they are affected by outside economic problems. Since the network makes things, we can call it a "Maker Network" or MakerNet.

The network as a whole would be self-directed and self-improving, rather than being directed from above. Members follow their interests and abilities. They teach, learn, and improve their skills when possible. They help each other to acquire new equipment and complete larger projects. They trade products and services within the network, and sell to other people to cover things the network can't provide.

A production network that supplies all the basic needs and some luxuries cannot solve other problems we face. The hope is by taking care of physical scarcity, people will have more time to deal with social, political, environmental, and other kinds of problems.

2.1 - Getting Started

[edit | edit source]

Founding a network requires an initial supply of labor, knowledge, funding, tools, materials, and power sources. Depending on the resources of the founding members, they may need time to accumulate enough of these items. Once several network nodes are in place, their experience, resources, and production capacity can be used to help set up additional nodes.

People with existing jobs but few other resources can participate as a spare-time activity that supplements what they already do. Reasons to begin include better use of their existing resources, hobby interests, and having backup work when conventional jobs are lacking. The under- or unemployed have more time available, but fewer resources. They may participate out of need for basic goods, to work their way out of poverty, or for self-improvement. Finally there are the retired and the wealthy who don't need to work themselves, but still can if they choose to. They can contribute funding, work space, and other resources. These people can combine their efforts to help each other and get more done.

Not everyone will start with the skills and experience to use the different tools and equipment. They can supply basic labor or other resources to start participating. They can later gain skills and experience by working with other members. The network can also supply formal training for those who want to learn new skills. People can also learn on their own from publicly available sources, then apply that knowledge to network projects.

New people may start with no tools or equipment of their own. If they have enough funds, they can simply buy them. If not, they can borrow or use existing tools in the network to get started. They can accumulate their own by trading labor, making them within the network, or building up an ownership share that lets them use larger collections.

2.2 - Growth

[edit | edit source]

At first, the network can only make a limited range of items. It doesn't meet all the members basic needs, or have all the equipment needed to make upgraded tools. So they make a surplus of the products and services they can make with the abilities and tools they have. These are sold or traded for the parts, materials, and equipment to upgrade. Surplus production can also be sold or traded to satisfy some of their personal needs.

At this stage the network can partly solve the job uncertainty problem. Whenever other work is not available, they can employ themselves within the network to compensate. As more people join the network, and their skills and equipment improve, they can do more for themselves and need less supplied from outside. Over time, members can build or acquire their own smart tools. This lets them make things very efficiently, with less of their labor needed. At this level they can replace conventional jobs entirely. Members can transition from working for others to working for themselves.

2.3 - Continuing Operation

[edit | edit source]

Working members of the network can later become disadvantaged by age or misfortune, and eventually pass away. They frequently will have non-working dependents. These people are unable to operate the tools and equipment themselves. They can still benefit from an ownership share in the equipment. New people would take up the necessary work, and acquire their own share of the network. Total productivity with advanced tools should be high enough that it can support current workers plus the beneficiaries of previous ones. With very advanced tools, the machines could mainly run themselves, with occasional supervision and maintenance in exchange for a share of the outputs.

Some people may have other goals than meeting their personal needs from within the network. For example, by working within a network, they could bootstrap an independent business without having to supply all the starting capital and equipment themselves, or going to outside financing. The network allows them to get started and be productive, accumulate these items and outside customers, then set out on their own when ready.

3.0 - Seed Factories

[edit | edit source]

We can make the growth of such self-improving networks easier by intentionally designing starter sets of equipment with that purpose in mind. We can also design them as integrated systems whose parts work together, and which avoid new problems and side effects as much as possible. Finally, we can plan a growth path to a mature production system, which in turn can produce new starter sets. This enables networks to replicate to as many copies as needed. We call a starter set suited for this type of self-expansion a Seed Factory, by analogy to plant seeds who grow into mature plants.

To set up a seed factory you need an initial supply of tools and machines. However, a collection of simple tools cannot do anything by themselves. You also need other resources such as raw materials, labor, and energy to operate them. Knowledge is also needed - in the form of plans and instructions for what to build, and as skills and experience of the operators so they know how to carry out the work. All of the inputs of Tools, Resources, Energy, and Knowledge are needed to make a complete system, capable of growing and copying itself. To help remember these components, we call this the TREK Principle, after the fictional replicators of the Star Trek universe.

A young network will have a limited ability to make things internally. A more mature production network may be able to build new starter sets, but still not internally supply everything it needs to function. For continued operation, seed factories and growing networks will generally need outside supplies of energy and materials. They will also need parts and machines which cannot be made internally, to replace worn out items or for expansion. Paying for these items can come from member contributions, product sales, or from outside sources.

If network nodes can complete projects or make individual items on demand we typically call them contractors or workshops. A starter set grows to become a factory when it can produce items in quantity by coordinated effort. With modern transport and communications, the tools and machines don't all have to be located in the same building or have the same ownership, like traditional factories. The owner/operators don't even have to be in the same place as the equipment if they can control smart tools remotely. The physical arrangement can be more distributed, like the modern Internet - concentrated activity in data centers, and local activity in people's homes and work places.

A modern Distributed Production System can have multiple machines in one place when it is more efficient to do so. But it can also have local equipment in or close to homes and local workplaces when that is preferred. What makes the system as a whole function like a factory is that all of the work is coordinated by people and their Information Technology. The result is the right amount of finished items are delivered when and where they are wanted.

3.1 - Design

[edit | edit source]

The shared features that make up a seed factory are that it enables self-expansion and upgrade, can grow to to meet the owners needs, resolves their economic problems, and eventually partly or fully replicate the starter set. In our examples later in this book and Volume II we will give suggestions on what equipment to start with, but those should be adjusted to what an actual project will need.

Starter Sets - There is no single fixed design for an ideal starter set. What you need depends on a number of factors. These include the economic resources and skills of the first network members, the finished products they want to start making for themselves, local environment conditions, and what supplies of tools, materials and parts are available to them. As progress is made in smart tools and other technologies, the best items to to start with will also change. For example, 3D printers became commonly available around 2010, so they were not an option before that time, but now are.

You can start operating with less than a full starter set. This may not have any ability to produce better tools, but can be used for simple products and services. For example, a pickup truck and utility trailer can't be used upgrade themselves. However, they can be used to supply moving services. The income from that can be used to buy other tools and materials, and the vehicle used to transport them to where a workshop will be built. Production can start after enough of the workshop is finished. Eventually a production network can fabricate improvements, such as an enclosed box for the trailer, completing the upgrade cycle.

Services can be supplied with limited equipment. That may be a better route to get started for those with limited resources. A larger group of people or more funding can shorten the path to growth by immediately setting up a working space with more advanced tools. A third approach is members first pooling their savings until they have enough to start buying equipment.

Growth Paths - Whatever starting point is chosen, it needs an effective growth path. One way to do this is to select flexible tools for the starter set. For example, a single solar furnace can be used to make bricks, cast metal parts, or dry lumber, all by using suitable attachments and accessories. Another way is modular design, so the expansions can be done in smaller steps. A production building can be added to one structural bay at a time. A generic electric vehicle chassis can have accessories like robot arms or farm implements added a piece at a time.

We don't know in advance what resources and skills a new group will have, or what they want to make first. A way to handle this uncertainty is to build up a library of growth paths, and individual item plans and instructions. They can then choose their own paths as needed. Previous groups can also help new ones by offering packaged sets of tools, training, and other help.

Design Approach - A smaller project like a home workshop doesn't need the full systems design method described in Chapters 3 and 4. There are enough reference sources like books, websites, and YouTube videos to provide guidance, and the owner knows what they have in available skills, tools, and space to build it. Workshops can also be built piece by piece, with changes and additions made as they become needed. Each step is simple enough not to need a lot of planning and design.

A modular production robotics suite, designed to be made and used within a growing production network, is much more complicated. It would include parts like robot arms, end tools, fixed mountings, mobile chassis, sensor suites, and manual controls. These will need software, computers, and date networks to operate. All these pieces have to fit and work together.

Designing a robotics suite like this will be too hard for a small group just starting out. There are several ways to ease the difficulty. First, part of the systems approach is to break down complex projects into smaller pieces that can be worked on individually. The design effort can also be shared across individuals and groups like open-source software by sharing new designs and plans across all the groups and networks building such systems. In fact, for smart tools, part of the design will be software, where there is a lot of experience in open-source methods.

3.2 - Cost

[edit | edit source]

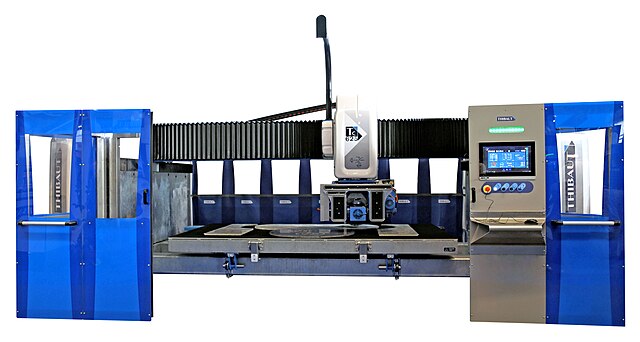

A new modern Machine Tool (Figure 2.1-1) may start at $45,000, and an industrial robot can start at $30,000. To use the most advanced production methods you generally need several machines in this price range, plus a medium-sized building to house them. This is too expensive for most individuals and small groups. There are several approaches to bring the cost within reach.

The first is to pool the resources of a larger group. Farm and electric cooperatives, and credit unions have long demonstrated that ordinary people can do larger projects when working together on a part-time basis. The cost of more expensive or less frequently used equipment can be divided in a similar way among network members. Single equipment items may be individually owned, then loaned or access provided to others, or operated by the owner and the products traded within the network. This way the whole group can benefit from their use. Some areas have community workshops called Hackerspaces or makerspaces. These already have collections of tools and equipment that can be used by members or the public. They can serve as starting points to grow from.

Second, smaller and simpler versions of most tools exist, some in kit form which costs less. Industrial-grade equipment is designed for continuous use. Home and hobbyist-grade equipment is more lightly built, use less expensive materials, and have smaller motors. These may be good enough for the early growth stages. They can be traded or sold later when upgrading. Third is buying used and older models rather than new.

Bootstrapping is a third approach. The first set of tools are used to supply products and services. The income is then used to buy additional/larger/better ones. The current set of tools can also be used to directly make new tools, in a planned series of expansions and upgrades. To the extent tools can be made, rather than bought, it lowers their initial cost by substituting the group's own work.

3.3 - Feasibility

[edit | edit source]

We know starter sets in general are possible. Civilization as a whole grew from smaller and simpler sets of tools. Settlers in new areas historically brought along a set of tools to start with. They also typically imported more tools for a while, until they could make their own. Our approach repeats this pattern. Modern homesteading and do-it-yourself projects show people can partly make what they want using their own tools. Factories that make robots and machine tools already use their own products to make more of the same types. This shows replication of complex tools is possible.

What we don't know are the optimal starter sets and growth paths to reach particular goals, given finite resources, modern technology, available designs, or what is likely to be possible in the near future. More work is needed to identify the best paths, prove them by building working examples, and build up experience with this approach.

Although we don't yet know everything about self-expanding systems, we do have some beliefs. One is that self-expanding production networks cannot function in isolation unless they are very advanced. They will have some level of interaction and trade with the rest of society. We also don't think bootstrapping can effectively be done by one person, because of the range of skills and amount of time required. But these are beliefs, and not yet proven.

3.4 - Necessary Inputs

[edit | edit source]

We noted that an initial supply of tools, resources, energy, and knowledge (TREK) are needed, before people can effectively provide products and services. In developed countries such as the US, a basic supply of these items is widely available at low cost. Many households already have some basic tools, especially if they are home-owners. If they follow a hobby they typically have better or more specialized ones. People who work in mechanical and construction trades tend to have better tools for their jobs, and people who work in manufacturing have access to even better ones.

Used tools can be obtained from online markets and exchanges such as eBay or Craigslist. They can also be found locally from thrift and pawn shops, flea markets, and yard sales. New tools are more expensive, but widely available locally and online. Getting some tools to get started should be feasible even for low income people, especially if several pool their resources.

Sources of raw materials and energy are also widely available at low cost, even though many people don't realize it. For large amounts, a typical acre of land (multiply by 2.5 for hectares) contains 100,000 tons of soil and rock in the top ten meters, worth about a million dollars at bulk quarry prices. It receives about 875 MWh/year of net usable solar energy, worth more than $40,000/year at wholesale rates. Outside large cities, US cropland is available for $1,100-15,900/acre ( USDA, 2022 ), and undeveloped land for even less. This is far less than their resource value. What is needed is an effective way to use these sources, which self-expanding networks can provide.

In developed areas, materials and energy can of course be purchased. But surprising amounts of materials are available second-hand, as scrap, or as discards. Small amounts of wood and metal can be found for free or low cost, such as discarded furniture, tree trimmings, scrap yards, etc. Self-built solar power can be very low cost, and free to use.

Finally, essentially all the world's knowledge is now available as e-books and other online sources. This is in addition to printed sources from libraries and book sellers. Many people also have skills and experience they can share with people who don't.

3.5 - Potential Advantages

[edit | edit source]

The bootstrapping approach may have a number of advantages over other solutions to current and future problems. It leverages a wider range of inputs than money-based income transfer programs. People who are able, but not fully employed, have a reserve supply of their own labor. This approach can put their available time to good use. Highly automated production can turn widely available resources into useful items at low cost.

In purely economic terms, this approach may have higher rates of return than conventional investments. With proper planning it can provide more economic security, a higher quality of life, and fewer environmental impacts than current methods. It does not change the fundamentals of trade and private ownership, so it can be implemented within the current economic and legal framework. If most of people's basic needs can be met with highly automated production, it also frees up their time to pursue their interests, rather than having to work out of necessity at a job they don't like.

We think this approach is better than alternatives like Basic Income transfer programs. Those can't scale to a future where most jobs are replaced by smart tools, because there won't be enough funding sources left. Government-run transfer programs are subject to political meddling, and therefore uncertainty. There will always be some who resent being taxed to give "free money" to others. Whoever is taxed to fund such programs will likely object and seek ways to avoid them.

Self-reliance and selfownership is better in terms of general acceptance, and people's own motivations and psychology. A sector of society will always need outside help, so the need for support programs will not go away. But we should consider bootstrapping as an approach to provide that help rather than traditional cash transfers. For example, public or charitable programs could loan out starter sets or individual tools until a new group or network is self-supporting.

4.0 - Example Starting Points

[edit | edit source]

Some simple examples can help clarify the ideas presented above. Later portions of these books will provide more detailed examples and the process of designing such systems. We don't yet know everything about self-expanding and self-improving systems. However, we think enough is known to begin their design and development.

The first example begins with a single product or service category, then expands to other categories over time. This is more suited to smaller groups with fewer skills and resources. The second one begins with a more complete starter set of equipment. It is more suited to a larger group with more skills and resources.

4.1 - Single Category Startup

[edit | edit source]

This route can begin with a single person or a small group. They start with a single category of product or service. Examples are sewing, carpentry/woodworking, or light household moving for hire. These don't require a lot of tools, and many people already have a sewing machine, some hand and portable power tools, or a pickup truck to get started with.

Sales outside the network are used to buy better tools and materials in their chosen category, then later used to expand to other categories as more people participate. Members also trade within the network and help each other with projects. People are unlikely to fully support themselves when starting this way. They will need conventional jobs or other outside support until the network has grown enough.

We can list startup categories, and the later expansions, according to the type of materials or services provided. Within each category they would begin with projects that need the fewest tools and skills, and are nearest to finished products. As tools accumulate and skills improve, they can start working back towards lower cost materials and larger scale of operation.

For example with woodworking, buying finished furniture from a store doesn't require any skills or tools, but has the highest cost. A shelf unit kit may require assembly, but all the parts are supplied. You only need simple tools to complete it. Making a set of shelves from bought lumber requires more tools and skills, and shaping and assembling more complex furniture would need even more. Finally, cutting trees, milling the resulting logs into lumber, and drying the wood requires the most tools and skills, and presumes a high volume of products. But sourcing wood directly from trees has the lowest cost of materials.

New people joining the network can follow their interests. They can start in other categories and follow similar upgrade paths. As more categories are added, members can start to support each other. For example, people doing concrete and metalworking can help expand a woodworking shop, and in return the woodworkers can supply furniture and cabinetry to the others. If a network can grow to cover all the main categories, it can supply a major fraction of people's needs, and further self-expand in an effective way.

Startup categories, with some first steps and upgrades include:

- Basic Tools - These include basic hand tools, like screwdrivers, hammers, and wrenches, and portable power tools like an electric drill, circular saw, or reciprocating saw. Besides household maintenance, basic tools are used to maintain other types of equipment, so this category is listed first. A basic tool set can grow by adding one item at a time. Methods like cleaning, oiling, and sharpening can restore or maintain other tools.

- Light Crafts - This includes small-scale crafts like jewelry, candle & soap making, and fine arts, which don't require large equipment or work space. They are distinguished from basic tools by needing specialized ones for a given craft.

- Carpentry & Woodworking - These use the basic tools, but applied to larger and more complex projects. To the basic ones are added tools like ladders, ropes, sawhorses, chisels, routers, table saws, and woodworking benches. These can be bought, found used, or self-made, and added one item at a time.

- Stone & Concrete - This can start with hand-laying of found stones, which needs very few tools, and using bagged pre-mix concrete that only needs water and a few tools to use. Larger projects can add tools for shaping stones, portable mixers, using concrete forms and block molds, and shaping and placing concrete reinforcement.

- Metalworking - Basic hand and portable tools can shape and drill thinner metal pieces. Heavier items require a furnace to heat and soften the metal, then hammers, stakes, anvils, or presses to shape it. Casting requires higher temperatures, crucibles, and molds. Many of these can be self-made. Machining is more advanced, and needs special tools that can be added one at a time.

- Glass & Ceramics - Cutting glass can be done with simple tools. Shaping glass and firing ceramics requires high temperatures, starting with devices like gas torches and firepits, moving up to more advanced furnaces.

- Polymers - Small plastic items can be molded with light craft tools, or shaped with woodworking equipment. Complex items need a 3D printer or laser cutter. These can be expensive/complex for starting out, but commercial services or community makerspaces can be used to make individual items.

- Electrical & Electronics - Electrical may start with simple repair, like replacing motors and cords, and work up to larger wiring projects. Electronics projects can begin with connecting pre-made items, like assembling an entertainment system or desktop computer, then moving to more complex ones involving custom circuit boards and programming.

- Coatings & Printing - Household painting and finishing furniture can start with just a few tools and supplies. More complex screen, spray, and paper printing methods can be added later.

- Fiber & Fabric - Hand sewing can be done with almost no investment in tools. Consumer sewing machines are widely available at low cost. Upgrading to industrial machines, and adding cutting and sewing tables and other equipment can be incremental. Working with other materials like leather or fiber-reinforced plastic requires specific tools that can be added later.

- Assembly & Construction - Mechanical assembly and welding can be started on a small scale, as can installation of items made by others, such as cabinets and appliances. Larger construction projects would go beyond carpentry and concrete to include earth-moving, utilities, and crane work. These can require larger equipment for short periods, so they are normally supplied by specialist companies. If used often enough on smaller projects, smaller versions of the equipment types are available.

- Agriculture & Forestry - This can start with small-scale home gardening and animal-raising that don't need many tools. Community gardens and farms require more land, tools, and people's time to get started, but can be expanded in steps. In suitable climates, growing trees may not require any work, just allowing them to grow. Harvesting can start with smaller bushes, saplings, and branches, and don't require a lot of tools, then gradually moving to larger size trees and quantities.

- Materials Processing - Most people are familiar with cooking food, which follows steps like mixing and heating, and they already have the equipment for it. Other materials can be converted from raw to finished by following a series of steps. These include mechanical, thermal, chemical, or electrical processes. A very simple example is air-drying of wood from the natural state, which is too wet, until it is dry enough for construction or furniture. This category can start single materials that only need simple steps, adding new ones individually. The tools and equipment for each step are acquired or made as needed.

Of the categories above, wood, stone, and metal. in their various forms, form the core of modern civilization. Historically our ancestors first used them in that order. If you look at something like a modern US house, they make up the majority of the materials by weight. So if the intent of a network is to supply basic needs, they are a good place to start.

Each of the above categories will need other resources besides tools. These include:

- Knowledge - This includes learning sources, skills, experience, and plans. Most people start with a level of general knowledge gained from early education. Books, online information, classes, working with more experienced people, and carrying out progressively harder projects can build personal knowledge. For anything beyond the simplest projects, plans and instructions for how to accomplish them are very helpful. These can be found for individual items as needed. For larger or custom projects, the ability to design and plan a sequence of steps, and coordinate the work of different people is needed.

- Work & Storage Space - Most types of work require some protection from the weather. Even outdoor categories like farming use protected areas for storage and maintenance. Such areas can start with temporary setups put away between uses in a spare room, garage, or basement. Later additions can include out-buildings added to current homes, leased or purchased commercial buildings, or undeveloped land which is then built on. Storage equipment can start with small tool boxes, drawers, and shelf units, and upgraded over time.

- Power & Lighting - These can start with conventional wall outlets and natural and artificial lighting. Portable power can be supplied from devices plugged into vehicles, portable generators, batteries, and dedicated engines. Solar and wind can provide more power for dedicated locations.

- Transportation - Most people have access to some sort of transportation, and can share the cost of larger transport within a network. Boxes and containers for moving items can often be found for free, or self-made for specific needs.

- Parts & Materials Supply - These can be purchased at retail to start with, and often found used or for free. As activity and tools increase, the network can obtain items earlier in the supply chain, eventually sourcing from raw materials.

4.2 - Industrial Startup

[edit | edit source]

A larger group, or one with more resources, can begin with a more advanced and complete starter set. They are able to immediately start making a significant percentage of new attachments and accessories for the original set, and making or buying complete new tools to upgrade their capacity. The starter set is planned as a unit, but can be added one item at a time. The owners can begin with partial operations until the full set is in place.

This example is intended for general-purpose industry, but it is not unique. Other starter sets can be designed to meet different needs. It includes eight main equipment types, with suitable accessories and attachments. The starter set would include at least one item of each type, and add more units and different capabilities with time.

- (1) Building and Support Equipment - Most tools and machines need some protection from the weather, especially the electronics of smart tools. People also benefit from sheltered work and design areas with good lighting. Storage areas are generally needed in addition to the workshop spaces.

To accommodate self-expansion, the building can be a modular design. For example shipping containers (Figure 2.1-2) can be a basic module. They are weather-proof, and can be used directly as work-spaces. They can later be arranged and stacked to form the walls of a larger building, on which a roof spanning between them is added. Another approach is a more conventional steel-clad industrial building, where one end is a temporary wall. Additional structural bays can be added one at a time to lengthen the building, moving the temporary wall as each bay is completed.

- The main tools and machines listed below need support equipment for tasks like grinding, sharpening, and measuring. Some basic portable and hand tools are also needed for maintenance. These items can be shared across different machines, so we group them together under this heading.

- (2) Modular Robots - This includes both stationary and mobile robots, driven by electric or hydraulic power. The robots are modular in design, so their configurations can change according to different needs. The stationary version uses jointed arms (Figure 2.1-3) and end tools, mounted on a fixed base or rails. The mobile version starts with a chassis that functions like a farm tractor, providing basic power and motion.

&esmp;A variety of attachments can be mounted on the chassis or pulled behind it, such as wagons, lifting arms and buckets, jointed robot arms, and specialty end tools and implements. Mobile versions can be used internally within a building, or outdoors for construction or farming work. One attachment would be a "manual control module", to allow people to control the machine directly. This is useful for unique tasks when programming the robot isn't worth doing.

- (3) Solar Furnace - Powered tools and machines require energy to function, and many processes require heat. A solar furnace can supply both. A collection of mirrors are mounted on an axis to follow the Sun (Figure 2.1-4) and focus the energy on a stationary point. Replaceable targets can be mounted at the focus for tasks like making bricks, melting metals, producing steam to generate electricity, or lower intensity heat for other processes.

Concentrator-type solar cells at the focus can produce electricity. The cells are not made in-house, but they only represent a small part of the furnace. Energy can be stored by directing the heat to an insulated rock bed, then extracted later as needed. Multiple copies of the furnace make it modular, and they can then be assigned to different tasks. Later versions can be built larger than the first one.

- A solar furnace can be mainly built from metal and glass parts. It can be designed to melt scrap of both types to cast new parts. So it can be largely self-reproducing from low cost materials. Large amounts of energy are needed for many industrial processes, so this may be a key path for self-expanding systems.

- (4) Bridge Mill - Mills are a basic type of Machine Tool, which cut or shape metals and other rigid materials. They come in a large variety of sizes from bench-top ones weighing hundreds of tons. They have two or more motion axes to position the working tools. Figure 2.1-5 is a large horizontal machine for cutting flat materials. In a bridge mill, the Horizontal Bridge can also move vertically on fixed posts, while the tool mount moves horizontally along the bridge. Versions with a sliding table move the part underneath to provide a third axis of motion.

- In an advanced version there can be four tool mounts, two on the front and two on the back sides of the bridge. This allows mounting up to four robot arms or various other tools at the same time. The bridge extends past the posts and table to tool-changers at the sides, so they can be swapped automatically. The rails that support the sliding table can be made as long as needed. New tables can be brought in with new parts to work on. Multiple tables can support very long work-pieces, sliding them under the bridge as needed. The tool mounts and tables can provide additional rotation or angled motion axes for more complex parts.

- (5) Horizontal Lathe - The bridge mill is better suited to rectangular or irregular parts. A lathe is better suited to round or symmetric parts, so we include it as a second basic machine tool. The simplest version of a lathe has a rotating spindle and drive motor (Figure 2.1-6) with a chuck to hold one end of a work-piece. A tailstock mounted on rails supports the other end of pieces of varying length. Cutting tools are applied as the piece rotates to generate round parts. Halting the rotation at known angles and moving a cutter along a plane can generate faceted sides.

- In an advanced version, the lathe would have four rails, such as the Weiler V-Series(pdf file). The second pair of rails allows multiple cutting heads carrying different tools to move independently into place as needed. Tool changers are mounted above the cutting heads to swap out different tools or replace worn ones.

- (6) Hydraulic Press - A hydraulic press can perform tasks like pressing shapes using dies and molds, shearing, rolling, bending, and shaping. One or more hydraulic pistons force the upper plate down, while several posts keep it parallel to the lower plate (Figure 2.1-7). The upper and lower plates are slotted to accept different inserts, and side supports can feed long objects for shearing, rolling, or bending. Thin or soft materials can be pressed at room temperature, while thick metal can be pressed hot, a process called Forging. In some cases the inserts would be heated, but they must use a higher melting material than the piece being worked. Like the machine tools, presses come in a variety of sizes and load capacities.

- (7) Process Plant - A variety of materials are typically needed in complex machines. Such materials are typically not found in the needed form in nature. They can be bought from others, but that increases costs and makes a system less able to self-expand.

- A large number of Production Processes are available to convert raw materials to the desired form (Chapter 4.3). Depending on what materials are needed, individual process steps, known as Unit Operations, are combined to form complete process flows (Figure 2.1-8}.

- All the process flows taken together, some of which may share steps, make up a process plant. An example flow for wood would include cutting the trees, bringing the logs to the sawmill, cutting the logs into pieces, and stacking them to allow drying. Each unit operation needs its own equipment to carry it out, and often energy and other inputs.

- For general industrial products, the process plant might take in scrap metal, use the solar furnace to melt it, cast basic shapes, then trim and grind as needed to feed the Mill, Lathe, and Press. Process plants can be made modular and flexible to follow different flows at different times. New equipment can be added one piec at a time to increase the range and quantity of products.

- (8) Electrical Shop - Machines and tools that use power, especially smart tools, need a variety of electrical and electronic parts. This includes wires, insulators, motors, generators, batteries, switches, relays, transformers, resistors, capacitors, inductors, filaments, circuit boards, and microelectronics. An Electrical Shop would produce and assemble as many of these items as is feasible.

- The shop accepts some parts and materials made elsewhere in the factory. Some items too complicated or difficult to make internally, such as modern computer chips. These items are purchased, but they make up a relatively small part of the factory. Used equipment or electronics people already own may be enough to control the industrial machines.

5.0 - Building the Future

[edit | edit source]

The previous two examples are aimed at solving problems of individuals and small groups in the face of increasingly smart tools. They are intended to meet the personal needs of their owners and the local community at a smaller or larger scale, so we call it Personal Production. But systems like these, which bootstrap from a starter set, then grow and improve themselves to whatever level needed, are not limited to solving economic problems. They can be applied at all levels of complexity and scale, just like living things range from microscopic bacteria to entire ecosystems.

Unlike biology, a network that begins with people and their knowledge can do more than just copy itself. People are the original "smart tools" - they can change and adapt. Once a network is put on a growth path, it can add new items not in the original plans, upgrade to higher levels of complexity, and expand to larger scales of operation. A network can also change course and make an entirely different set of products and services, if that is what the owners want. Finally, existing networks can also produce new equipment sets with different purposes than the original, and spawn whole new growth patterns.

5.1 - Beyond Personal Production

[edit | edit source]

There are other ways to use self-improving systems beyond the two personal production examples we gave. We list some of them here and they are included as examples later in these books. We think such systems are worthy of study and are inherently interesting. But we don't think such projects are ready for smaller groups to jump in and start building yet. We think more basic research and development is needed, and gaining experience with smaller and simpler projects first.

Increasing Scales - A network of people working together can keep upgrading and expanding their equipment and adding new members. This can take them beyond personal goods and services, into the small business and commercial scales of operation. This goes beyond meeting their own needs, to meeting the needs of people and businesses outside their immediate family, friends, and neighbors. The larger network will tend to include people in multiple locations, so we call it Distributed Operations. The final growth step is to industrial scale, reaching more widespread markets and at the most efficient levels of operation.

As activity grows to larger scales, it will tend to become more specialized. This is because it gets harder to find places large enough, or with all the right conditions, for multiple industrial-scale operations. Although physically separate, the various locations can still support and supply each other as part of a network. Just because part of a network has grown to larger scales, it does not mean the whole network has to. It can include a mix of activity ranging from small to large sizes.

Harder Environments - The previous examples assume moderate environments in already developed areas. These are the kinds of places where most people already live and work. But these places only encompass about 13% of the Earth's surface, and on average only a small distance above and below it. Highly automated and low cost production could make it affordable to live and work in harder environments, and use more of the material and energy resources found there.

Difficult environments include open waters on oceans and lakes, very cold or ice-covered areas, hot and dry desert regions, very wet and swampy areas, high altitudes, depths underwater and underground, and places which are currently too remote and undeveloped to use. Different starter sets would be needed for all these different conditions, but they could be produced by previous generation automated factories in the easier locations.

The hardest environments are beyond the Earth in outer space. In addition to other difficulties encountered on Earth, you add problems like lack of gravity, air to breath, and high radiation levels. Large distances are involved, and large amounts of energy are needed to traverse them. The challenges and costs of large space projects are in fact the reason the idea of bootstrapping from an automated seed factory was first considered. But since there isn't yet experience in such projects, we think it makes sense to start on Earth, where conditions are easier, and leave space for last.

The starter sets for both harder environments on Earth and space locations would be produced in existing locations, then shipped to where they need to be. So logically the easier projects should come first. Once starter sets are delivered to any of these harder locations, their low population ensures relatively large amounts of local energy and raw materials are available to use. As with previous networks in easier place, some items are too hard to make locally, or use rare materials. These would continue to be supplied from elsewhere.

A Better Future - Future civilization can develop along utopian or dystopian lines. We believe where we end up is a choice, not an inevitability. If we use them wisely, smart tools and self-expanding systems can help us build the kind of future we want to live in. First, by supplying basic needs like food, shelter, and utilities, people would no longer be subject to the kinds of economic problems and uncertainties we previously discussed. Highly efficient production would free up people's time, and allow them to do what is interesting, rather than what is necessary survive.

Low cost production can enable high levels of renewable energy and recycling. This would reduce or reverse environmental problems. People would have more choices of where and how to live. The development of space would greatly increase available energy and materials. It could offload intensive industries from our planet, further improving the environment. This is a much more optimistic future than some believe in.

5.2 - Some Final Thoughts

[edit | edit source]

emsp;We end this chapter with some final thoughts of a more philosophical than engineering nature, and some ideas that need more work.

Self-Reliance and Personal Contact - Modern humans are a mobile species. We originated in Africa, and spread to all parts of the world with reasonable climates, and even some that are unreasonable. During our migrations we necessarily had to use local resources, and carry or make starter sets of tools to live in these new places. We are also a social species. We relied on ourselves and the network of people around us to do these things.

With the advent of industrialization, large cities, and large organizations, we have gotten out of the habit of relying on ourselves and people we know. We have become dependent on distant farmers and factories to supply our daily goods. Shareholders we have never met own the companies where we work to afford those goods. This puts us at the mercy of forces beyond our control. We can be told "sorry, we don't make that product any more", or "you've been replaced by a robot", with no recourse from those decisions. It is easier to treat workers as disposable, and make things they don't really need or want, if you don't know them. A return to some level of working for ourselves and dealing with people we know would be an improvement.

Artificial Life - The combination of smart tools and self-expanding systems can be considered a form of artificial life. In principle, a collection of sufficiently smart tools can grow unassisted by adding to their number, and reproduce by copying the original collection. Self-growth and reproduction are properties usually associated with life. If the smart tools require people to do some of the tasks, we can consider it assisted growth and reproduction.

Alternately we can consider the people plus their tools as a higher level ecosystem which can grow and copy itself. The individual tools and machines are then analogous to the organelles of Eukaryote cells. Uncontrolled growth and reproduction can cause problems similar to biological plagues and cancers. Some thought should go into avoiding such problems, and how to deal with them.