A-level Applied Science/Colour Chemistry/Dyes

Dyes are soluble, coloured compounds.

Pigments are insoluble - see Dyes and pigments.

Chromogens are substances which are readily converted into dyes or pigments.

Experiments

[edit | edit source]Basic dye

[edit | edit source]Basic dyes are water-soluble cationic dyes that are mainly applied to acrylic fibres, but find some use for wool and silk. With cellulosic fibres an anionic tannic acid mordant is required. Usually ethanoic ('acetic') acid is added to the dyebath to help the uptake of the dye onto the fibre. Basic dyes are also used in the colouration of paper.

The first synthetic dyes, such as mauveine (developed in 1856), are basic. They have a wide colour range, but a reputation for poor light fastness. Modern basic dyes are light fast, and if water can be excluded from the chemical structures the lightfastness is further increased. They are fairly fast to washing except on acrylics; however, the newer basic dyes are very fast on acrylics. They contain a =NH2+ or a -NH3+ group, giving them a charge in solution of +1.

Vat dye

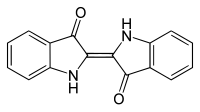

[edit | edit source]Vat dyes are an ancient class of dyes, based on the natural dye, indigo, which is now produced synthetically. Modern vat dyes (1901) include anthraquinone derivatives, but indigo remains the most important vat dye. They are useful mainly for cotton; but also for wool and other fibres.

The process "vat dyeing" refers to dyeing in a bucket or vat. It can be performed whenever a solid, even shade over the entire garment is desired. Almost any dye can be used, including fiber reactive dyes, direct dyes, and acid dyes. One alternative to vat dyeing is direct dye application, such as the process used for tie dyeing. "Vat dyes" are a special class of dyes that work with a special chemistry. Note that not all vat dyeing is done with vat dyes!

About Vat Dyes

Most vat dyes are less suitable than, say, fibre reactive dyes, for the home dyers, as they are difficult to work with; they require a reducing agent to solubilise them. The dye is soluble only in its reduced (oxygen-free) form. The fibre is immersed repeatedly in this oxygen-free dyebath, then exposed to the air, whereupon the water-soluble reduced form changes colour as oxygen turns it to the water-insoluble, oxidised form. Indigo is an example of this dye class; it changes from yellow, in the dyebath, to green and then blue as the air hits it.

Instructions for dyeing with vat dyes

PRO Chemical & Dye, which sells some vat dyes, provides instructions online for Immersion Dyeing using PRO Vat Dyes. The process requires the use of lye (sodium hydroxide), which must be used with due care, including the use of safety goggles.

Indigo is subject to major crocking (rubbing off of the dye onto other items) unless it is applied carefully. This means use a weaker dyebath, and dipping many times, rather than a single strong dipping.

Light-oxidised Vat Dyes

Ink-o-dye is a type of vat dye which uses light rather than oxygen to 'fix' the dye, with an inspirationally wide variety of possible effects. These dyes, which are chemically similar to vat dyes, Inkodyes are developed by light instead of being applied in an oxygen-free bath and being developed in the fabric by exposure to oxygen. Inkodyes are true dyes, not fabric paints. (A dye actually itself attaches to the fabric; fabric paint includes a glue-like binder, which imparts a stiffer feeling to the fabric.) The process is more difficult than the process of tie-dyeing with fiber reactive dyes. One retail source of Inkodye is Dharma Trading Company.

Further Reading

Imagery on Fabric by Jean Ray Laury

The Chemistry of Vat Dyes by Dianne Epps

Acid dye

[edit | edit source]Acid dyes (developed in 1862) are water-soluble anionic dyes that are applied to fibres such as silk, wool, nylon and modified acrylic fibers using neutral to acid dyebaths. Attachment to the fibre is attributed, at least partly, to salt formation between anionic groups in the dyes and cationic groups in the fibre.

Acid dyes are have good fastness if the appropariate dye is chosen; but in general they are not substantive to cellulosic fibres. They have a good colour range.

Chemically they are carboxylic or sulphonic acid salts used in an acid dye bath. In the home or art studio, the acid used in the dyebath is often vinegar ('acetic' or ethanoic acid) or citric acid. The dye molecule forms an anion with a charge of -1 to -4, occasionally more.

In textiles, acid dyes are effective on protein fibers, i.e. animal hair fibres like wool, alpaca, mohair and silk. They are effective in dyeing the synthetic fibre nylon but of minimal interest in dyeing any other synthetic fibres.

Acid dyes are generally divided into three classes which depend on fastness requirements, level dyeing properties and economy. The classes overlap and generally depend on type of fibre to be coloured and also the process used.

Acid dyes are thought to fix to fibres by hydrogen bonding. They are normally sold as the sodium salt therefore they are in solution anionic. Animal protein fibres and Nylon fibres contain many cationic sites therefore there is an attraction of anionic dye molecule to a cationic site on the fibre. The strength (fastness) of this bond is related to the desire/chemistry of the dye to remain dissolved in water over fixation to the fiber.

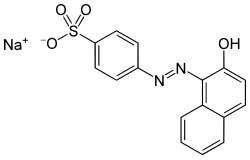

Structures

[edit | edit source]The chemistry of acid dyes is quite complex. Dyes are normally very large aromatic molecules consisting of many linked rings. Acid dyes usually have a sulphonyl or amino group on the molecule making them soluble in water. Water is the medium in which dyeing takes place. Most acid dyes are related in basic structure to the following:

Many acid dyes are synthesised from chemical intermediates which form anthraquinone-like structures as their final state. Many blue dyes have this structure as their basic shape. The structure predominates in the levelling class of acid dye.

Although Azo dyes are a separate class of dyestuff mainly used in the dyeing of cotton (cellulose) fibres many acid dyes have a similar structure, most are red in colour.

Triaryl acid dyes predominate in the milling class of dye.

Classes of acid dyes

[edit | edit source]Equalising/levelling acid dyes:

Highest level dyeing properties. Quite combinable in trichromatic shades. Relatively small molecule therefore high migration before fixation. Low wet fastness therefore normally not suited for clothing.

Milling acid dyes:

Medium to high wet fastness. Some milling dyes have poor light fastness in pale shades. Generally not combinable - used as self shades only.

Metal complex acid dyes:

More recent chemistry combined transition metals with dye precursors to produce metal complex acid dyes with the highest light fastness and wet fastness. These dyes are also very economical. They produce, however, duller shades.

Health and safety

[edit | edit source]Any dyes including acid dyes have the ability to induce sensitisation in humans due to their complex molecular structure and the way in which they are metabolised in the body. This is extremely rare nowadays as we have a much greater understanding through experience and knowledge of dyestuffs themselves. Some acid dyes are used to colour food. We wear fabrics every day exposing our skin to dyes.

The greatest risk of disease or injury due to dyes is by ingestion or exposure to dye dust. These scenarios are normally confined to textile workers. Whereby the dye itself is normally non toxic, the molecules are metabolised (usually in the liver) where they may be broken back down to the original intermediates used in manufacture. Thus many intermediate chemicals used in dye manufacture have been identified as toxic and their use restricted. There is a growing trend among governments to ban the importation of dyes synthesised from restricted intermediates. For example: the dye CI Acid red 128 is banned in Europe as it was found to metabolise in the body back to ortho-toluidine, one of its chemical intermediates. Many intermediates used in dye manufacture such as o-toluidine, benzidine etc. were found to be carcinogenic. All the major chemical companies have now ceased to market these dyes. Some, however, are still produced but they are found to be totally safe when on the fiber in its final state. The use of these dyes is declining rapidly as cheap and safer alternatives are now easily available.

The incident concerning the dye Sudan 1 is an example of a suspected toxic dye finding its way into the food chain. Such incidents are extremely rare.

Fibre reactive dye

[edit | edit source]Fibre reactive dyes utilise a chromophore containing a substituent that is capable, when activated, of directly reacting with the fibre substrate. The covalent bonds that attach reactive dyes to the fibres' amine or hydroxyl groups make them among the most permanent of dyes.

Reactive dyes first appeared commercially in 1956, after their invention in 1954 by Rattee and Stephens at the ICI Dyestuffs Division site in Blackley, Manchester, UK. The dyes contain a reactive group, either a halo-heterocycle or an activated double bond, that, when applied to a fibre in a weakly alkaline dye bath, forms a chemical bond with a hydroxyl group on the cellulosic fibre.

Trichlorotriazine is a common reactive group:

Its three chlorine atoms can readily form HCl with a hydrogen from -OH or -NH2, leaving the O or N attached to the triazine ring in place of the Cl.

"Cold" reactive dyes, such as Procion MX, Cibacron F, and Drimarene K, are very easy to use because the dye can be applied at room temperature. Reactive dye is by far the best choice for dyeing cotton and other cellulose fibres at home or in the art studio. Reactive dyeing is now the most important method for the colouration of cellulose fibres. Reactive dyes can also be applied on wool and nylon, in the latter case they are applied under weakly acidic conditions.

Reactive dyes are available in a good range of colours.

For more info Fundamental Chemistry of reactive dyes

Other reactive dyes:

- Carbene dyes

Direct dye

[edit | edit source]Direct or substantive dye molecules (developed 1884) are attracted by intermolecular forces to the textile. The amount of this attraction is known as "substantivity": the higher the substantivity the greater the attraction of the dye for the fibre. They are easy to apply (‘direct’ means ‘without mordant’) and come in a wide range of colours.

Direct dyeing is normally carried out in a neutral or slightly alkaline dyebath, at or near boiling point, with the addition of either sodium chloride (NaCl) or sodium sulphate (Na2SO4). Direct dyes are used mainly on cotton and paper; but also with leather, wool, silk and nylon. Some are used as pH indicators and as biological stains.

Direct dyes are fairly fast to washing, and this can be improved by after-treament. Some have high light fastness. Chemically, the dyes contain the sulphonate group, essential for water-solubility. The more groups, the more water-soluble. Usually 2-4, occasionally 1 or 5 groups. The chromophore is usually azo type.

Disperse dye

[edit | edit source]Disperse dyes were originally developed (1923) for the dyeing of cellulose acetate, but can also be used to dye nylon, triacetate and polyester fibres. They are fast if the correct dye is selected for the fibre. Acrylics can be dyed with disperse dyes, but are only moderately fast and will not take intense dyeing.

Chemically, disperse dyes are water-insoluble azo and anthraquinone dyes. The dyes are finely ground in the presence of a dispersing agent and then sold as a paste, or spray-dried and sold as a powder.

The dyes are applied as dispersions (emulsions). In some cases, a dyeing temperature of 130 °C is required, and a pressurised dyebath is used. The very fine particle size gives a large surface area that aids dissolution to allow uptake by the fibre. The dyeing rate can be significantly influenced by the choice of dispersing agent used during the grinding.

Disperse dyes are available in a wide range of colours.

Azo dye

[edit | edit source]Azo dyeing is a technique in which an insoluble azo dye is produced directly onto or within the fibre. This is achieved by treating a fibre with both diazoic and coupling components. With suitable adjustment of dyebath conditions the two components react to produce the required insoluble azo dye. This technique of dyeing is unique, in that the final colour is controlled by the choice of the diazoic and coupling components.

Azo compounds generally have a molecular formula of the form R-N=N-R', in which R and R' can be either aromatic or aliphatic. The N=N group is called an azo or diimide functional group. The aromatic groups help to stabilise the N=N group by making it part of an extended delocalised system. This also has the effect of making many azo compounds coloured, as delocalised or conjugated systems often absorb visible frequencies of light.

The name azo comes from azote, an old name of nitrogen that originates in French and is derived from the Greek a (not) + zoe (to live). Aromatic azo compounds (R = R' = aromatic) are usually stable and have vivid colors such as red, orange, and yellow. Therefore, they are used as dyes, which are called azo dyes. Some azo compounds, e.g. Methyl orange, can also be used as acid-base indicators, due to their ability to function as weak acids, and the different colours of the acid and salt forms. Azobenzene is another typical aromatic azo compound. Their colour originates from absorbance in the visible region of the spectrum due to the delocalisation of electrons in the benzene and azo groups forming a conjugated system, whereby the N=N group is the chromophore.

Aliphatic azo compounds (R and/or R' = aliphatic) are rather unstable. At an elevated temperature or by irradiation, two carbon-nitrogen (R-N) bonds are cleaved simultaneously with the loss of nitrogen gas to generate carbon-centered radicals.

Aromatic azo compounds can be synthesized by using an azocoupling reaction, that is, an electrophilic substitution reaction on aromatic rings with diazonium salts. Diazonium salts decompose at temperatures warmer than about 5 degrees Celsius, so the reaction must take place in solution under freezing conditions:

Anthraquinones

[edit | edit source]| Template:Chembox header| Anthraquinone | |

|---|---|

| |

| Chemical name | Anthraquinone |

| Chemical formula | C14H8O2 |

| Molecular mass | 208 g/mol |

| CAS number | [84-65-1] |

| Density | x.xxx g/cm³ |

| Melting point | 286 °C |

| Boiling point | 379.8 °C |

| SMILES | O=C2c1ccccc1 C(c3c2cccc3)=O |

| Template:Chembox header | Disclaimer and references | |

Anthraquinone (9,10-dioxoanthracene) is an aromatic organic compound. It is a derivative of anthracene. It has the appearance of yellow or light grey to grey-green solid crystalline powder.

Its other names are 9,10-anthracenedione, anthradione, 9,10-anthrachinon, anthracene-9,10-quinone, 9,10-dihydro-9,10-dioxoanthracene, and trade names Hoelite, Morkit, Corbit, and others.

Natural occurrences

[edit | edit source]Anthraquinone naturally occurs in some plants (e.g. aloe, senna, rhubarb, and Cascara buckthorn), fungi, lichens, and insects, where it serves as a basic skeleton for their pigments. Natural anthraquinone derivates tend to have laxative effects.

Industrial applications

[edit | edit source]Anthraquinone is used in production of dyes, such as alizarin. Many natural pigments are derivatives of anthraquinone.

Sulphonic dye

[edit | edit source]Direct dyes and acid dyes contain sodium sulphonate groups.

Triaryl dye

[edit | edit source]

Dyes having structures related to triphenylmethane are known as triaryl ('aryl' refers to the 'phenyl' (benzene) rings).

There are many yellow and green dyes commercially applied to fibres that are related to triphenylmethane.

Cationic dye

[edit | edit source]See Basic dye

Anionic dye

[edit | edit source]See Acid dye

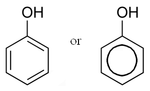

Polyphenols

[edit | edit source]Many coloured plant compounds are classed as polyphenols as they contain multiple benzene rings with multiple -OH groups attached. (A benzene ring with a single -OH group is called phenol.)

The main active dye in turmeric is the polyphenol curcumin:

Demethoxycurcumin and bis-Demethoxycurcumin are also present, in smaller quantities. They lack one or both methyl groups present in curcumin.

Flavonoids are polyphenols based on the flavone structure:

The yellow dye in onion skins is made a of mixture of flavonoids: quercetin, kaempferol and quercetin-3-glucoside.[1]

|

|

|

Halochromic dyes and Indicators

[edit | edit source]A halochromic material is a material which changes colour when pH changes occur. The term ‘chromic’ is defined as materials that can change colour reversibly with the presence of a factor. In this case, the factor is pH. pH indicators have this property.

Halochromic substances are suited for use in environments where pH changes occur frequently, or places where changes in pH are extreme. Halochromic substances detect alterations in the acidity of substances, such as detection of corrosion in metals.

Curcumin is a halochromic dye - at high pH its -OH groups become ionised to -O- and its colour changes from red to yellow.

Redox indicators are not halochromic. These compounds change colour according to whether they are oxidised or reduced.

Indigo (left) is blue and insoluble when oxidised, but is colourless and soluble when reduced (right). In the reduced state it is known as leucoindigo.

|

|

| Indigo | LeucoIndigo |

Methylene blue is another example.

References

[edit | edit source]- The Essential Chemical Industry (1985) Polytechnic of North London.

- Aspland, JR (1993) Chapter 12: The application of basic dye cations to anionic fibers: Dyeing acrylic and other fibers with basic dyes. Textile Chemist and Colorist Vol 25, No 6 June 1993 21-26

- Aspland, JR (1991) Chapter 2/Part 2: Direct Dye Structure. Textile Chemist and Colorist Vol 23, No 12 December 1991 30-32

- StainsFile Dyes used in microbiology, with good details given.

- ↑ Lokhande, HT & Dorugade, VA (1999) Dyeing Nylon With Natural Dyes, American Dyestuff Reporter Feb. 1999 29-34