Chromolithography

Chromo, Greek: krohm = colour + lithos = stone + graphy = style of drawing. A printing process discovered in 1798, by chance. Alois, or, Aloys Senefelder, 1771–1834. Born in Prague, Bohemia, on 6 November, was the son of an actor. Studied law, at Ingolstadt before taking up writing, became interested in copperplate engraving. Having all the necessary equipment and tools ready to create an engraving, including an ink mixing slab - made out of a cut, and smoothed, Bavarian limestone, he jotted down a list, on the slab in printers ink. Later, wishing to wash-up the slab, discovered that even though his cloth was damp the writing refused to be removed. The more he tried, getting some of the ink on the damp cloth in the process, found that this ink transferred back – re-inked the writing… The damped stone, having absorbed the water from the cloth, did the reverse - rejected the ink. This prompted: could an image be inked-up without touching the non-image areas - using a damped, non-image area, to reject the ink? The successful aim: of making a copy, by applying pressure to the back of a sheet of paper which is in contact with the inked image - a copy made by transference. Senefelder furthered his discovery throughout his life, writing a book about his work, which was published in 1818.

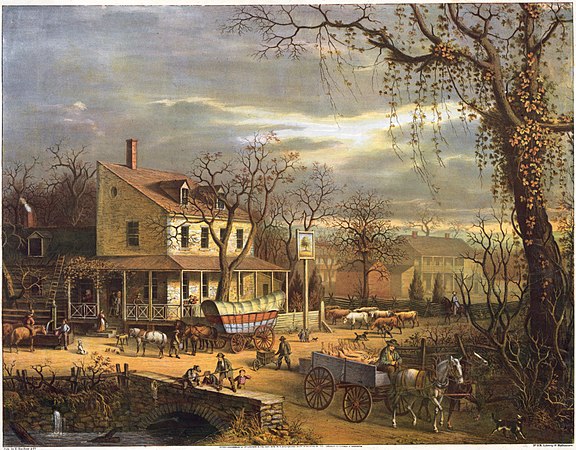

From the late 1700s, commercial lithographic printing produced coloured reproductions cheaper and easier than the letterpress process. The reproductions were also closer to the original. To achieve a first class reproduction ten or more colours were printed on top of each other in register. Although the reproductions were of a high quality the process was expensive and slow; it was reserved for special quality work – greetings cards and small labels, leaving the bulk of picture reproductions to the engraving process. The small reproductions printed from stone could be easily transferred to make-up repeated images. This made the process more viable. In 1822, it was demonstrated that ‘by overprinting several colours’ the lithographic process could make a reasonable reproduction of a coloured original, even though the number of copies were still limited.

By 1850 lithography was becoming the most productive process where quality was required. Steam-powered litho cylinder machines, were beginning to be introduced… becoming more common - within twenty years. Machine printing required a firm hard image made from using ink rather than crayon. This required a polished stone surface, not grained… as the image had to be composed of small solid dots, made by a pen and ink - to give vignettes and soft edges. This was known as stippling. The coloured picture made up by over-printing a number of colours – printed on top of each other - of tiny dots, ticks, and cross hatchings, to reproduce the original artwork.

The first lithographic printing surface was that of a smoothed, locally hewn, limestone, which retained its quality - remained damp when water applied. Later… grained aluminium and zinc plates took the place of stone – a surface medium able to wrap round a printing cylinder. Kelheim limestones are cut in the quarry three to four inches thick - for various machine sizes… then, given rounded edges and corners. The stones then either polished or grained depending on the size of the ‘run’ and the ‘quality’ required. Initially, Senefelder used a smooth ungrained surface to copy his music. When illustrating his work he produced tonework with a pen and ink – to produce stipple work [dots], or scraped away a solid patch - to give a line, crosshatched or woodblock effect. Later, for commercial jobs, the stone’s surface grained - to allow crayon-work to be used – to give a pencil tint. Graining also increases the surface area - allows the dampening effect of water to last longer – allowing a greater number of prints to be made.

The invention of the rotary press allowed offset lithography to be achieved - using a second machine cylinder to hold a rubber blanket. When the rubber blanket accepts the inked impression from the printing plate it transfers the ink to the paper… this process allows the artists plate or stone to be drawn ‘right reading’. Both the grained stone and metal plate retains water – the stone absorbs water and the grained plate traps the water in the grain. The grain allows a greasy black crayon, or ink, to be used to copy the original, making the reproduction closer to the artist original artwork. Out of all the reproduction processes drawn lithography reproduces pencil sketches, crayon, charcoal perfectly – in a free sketched manner, liberated… by treating the printing surface like paper or canvas.

Coloured lithographs under 40x30 inches are called chromolithographs, lager sizes called posters. Prints made for the art market are chromolithographs are not much larger than 30x20 inches, and often a great deal smaller. There can be no mistaking the impression for they show thin, transparent colours, with a fairly large tonal range, the image broken up by a random grained, crayoned appearance. Various techniques are available to the artist to achieve any special effects needed. They range from airbrush to Ben Day medium work… crayons to stump work, sponge and scraper.

The stone’s grained surface is produced by rotating a levigator, [trade name for a hand spun metal wheel… mimicked a corn mill], or, spinning two stones in contact - grained two stones simultaneously. Both these methods used graded qualities of silica sand - as aggregate, plus copious amounts of water [old work removed by the same process]. Steel straight edges provided an accurate level. When graining metal printing plates the same principle applied - a graining machine oscillates – as a rotating bed, using various sizes of metal or glass marbles - depending on the finished grain size required. Whether stone of metal plate, the final grained surface is washed and prepared using a very weak acetic acid – cleans the surface by removing any grease particles – giving the surface an even greater grease receptiveness.

The lithographic hand press uses both the principles of a letterpress screw press – for pressure, the engravers reciprocating press – to produce a larger print size and the operation of a scraper bar on the tympan - greater, directed, pressure. The first hand press, using the same principle as a clothes mangle, plus a scraper blade, instead of a wooden roller, was built at the turn of the eighteenth century – just after the discovery of the process. Fifty years later, in the 1850s, lithography became the premier printing process for monotone and colour.

The changes that did come about to the lithographic and letterpress processes in the first hundred years, concerned mechanics, not principle - the use of metal rather than wood- in the construction of the press and the type. Later, the use of rotary action rather than reciprocation further advanced each process until, finally… conversion - of the coloured continuous tone picture, by the photographic halftone principle. The photographic reproduction of coloured originals had a relatively short life span. Eventually, in the 1980s, the electronic revolution began by introducing colour scanners… ink toners, and laser jet printing.

Contents

[edit | edit source]Authors

[edit | edit source]- Terence Kearey