3D Printing/Printable version

3D printers contain a number of functions that can be dangerous in some instances. Therefore safety is an important aspect of operating a 3D printer. |

| This is the print version of 3D Printing You won't see this message or any elements not part of the book's content when you print or preview this page. |

The current, editable version of this book is available in Wikibooks, the open-content textbooks collection, at

https://en.wikibooks.org/wiki/3D_Printing

History

Origins

[edit | edit source]In 1982 modern 3D Printing was devised by Dr. Hideo Kodama.[1]

In Charles Hull invented sterolithography in 1984.[2] Scott Crump would invent FDM (FFF) printing in 1989.[3]

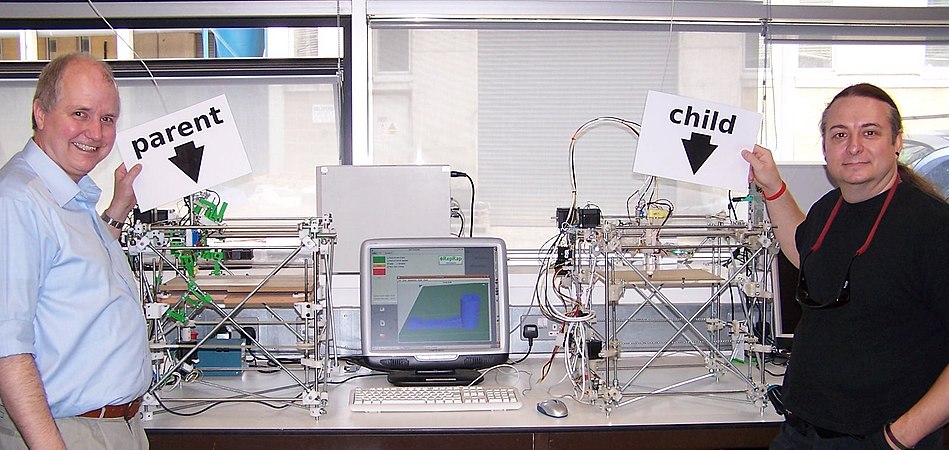

Starting in 2004 the Open Source Rep Rap project resulted in a number of derivative commercial printers being made that were more affordable then previous offerings.[4][5]

-

The first RepRap printed RepRap part in 2006.

-

The first replicated RepRap printer.

-

A RepRap 0.1 printing.

-

A RepRap Darwin in 2007 or earlier.

Adoption

[edit | edit source]The then cheap and open source 3D printers offered by Makerbot caught the public imagination around 2010.[6][7] In 2012 Makerbot stopped open sourcing hardware and soon was acquired by Stratasys, where it would soon cease manufacturing their own printers in 2016.[8][9][10]

The 3D printer market contracted a bit in 2015.[11][12] Budget Creality printers became popular during this time.[13]

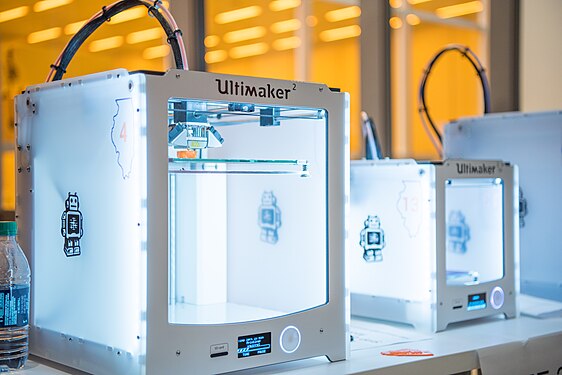

In the 2010's, both LulzBot and Prusa operated their own commercial scale printer farms to produce parts for their commercial 3D Printers.[14][15]

In 2020 during the COVID-19 pandemic, makers used tools like 3D printers to produce millions of PPE parts while supply lines were disrupted.[16][17]

-

Makerbot founders with Makerbot CupCake prototype in 2009.

-

A 3D printer for sale in a supermarket in 2016.

-

3D printers at a hackathon in 2016.

References

[edit | edit source]- ↑ "What You Need to Know About 3D Printing". Technology Transfer. Retrieved 29 November 2020.

- ↑ "History of 3D Printing Makerspace". Retrieved 29 November 2020.

- ↑ "Closing the Loop On 3D Printing". UCSF Library. 30 November 2017. Retrieved 29 November 2020.

- ↑ "Materializing information: 3D printing and social change". journals.uic.edu. Retrieved 29 November 2020.

- ↑ "The Brutal Edit War Over a 3D Printer's Wikipedia Page". www.vice.com. Retrieved 29 November 2020.

- ↑ "Making the Makerbot, A DIY 3-D Printer". Popular Science. Retrieved 30 November 2020.

- ↑ Simonite, Tom. "Rise of the replicators". New Scientist. Retrieved 30 November 2020.

- ↑ Brown, Rich. "Pulling back from open source hardware, MakerBot angers some adherents". CNET. Retrieved 30 November 2020.

- ↑ Sharma, Rakesh. "The Real Reason Stratasys Bought MakerBot". Forbes. Retrieved 30 November 2020.

- ↑ "The MakerBot Obituary". Hackaday. 28 April 2016. Retrieved 30 November 2020.

- ↑ "People Aren't Buying 3D Printers Anymore, So Companies Are Refocusing on Health". www.vice.com. Retrieved 29 November 2020.

- ↑ "MakerBot lays off 20% of its staff—again". Fortune. Retrieved 29 November 2020.

- ↑ "Creality Ender 3 vs CR-10: The Differences". All3DP. 15 July 2019. Retrieved 30 November 2020.

- ↑ "The 3D Printers that Print 3D Printers". www.vice.com. Retrieved 29 November 2020.

- ↑ "Three hundred 3D printers in one room: A quick look to our printing farm". Prusa Printers. 9 February 2018. Retrieved 29 November 2020.

- ↑ Commissioner, Office of the (13 November 2020). "3D Printing in FDA's Rapid Response to COVID-19". FDA. Retrieved 30 November 2020.

- ↑ Choong, Yu Ying Clarrisa; Tan, Hong Wei; Patel, Deven C.; Choong, Wan Ting Natalie; Chen, Chun-Hsien; Low, Hong Yee; Tan, Ming Jen; Patel, Chandrakant D.; Chua, Chee Kai (September 2020). "The global rise of 3D printing during the COVID-19 pandemic". Nature Reviews Materials. pp. 637–639. doi:10.1038/s41578-020-00234-3. Retrieved 30 November 2020.

Printer Types

Fused Filament Fabrication (FFF)

[edit | edit source]FFF printers operate by melting material from an extruder to produce a 3D object.

FFF printers are known for being easier to use than other printing technologies, partly due to requiring less safety equipment for operation.[1] Cartesian FFF 3D printers work by moving an extruder along an X, Y, and Z, axis.[2]

On Stratasys 3D printers the name FDM is used for the same technique.

-

A Prusa i3, a common cartesian FFF 3D printer. Cartesian 3D printers have a cuboid build area.

-

A Fisher Delta RepRap 3D Printer. The build area on a delta printer is a cylinder with a conic top.

Stereolithography (SLA)

[edit | edit source]SLA printers use light to solidify a special liquid.[3][4]

Unlike an FFF printer, SLA printers build time is based on height and not the number of prints or object complexity, so the entire x and y build area can be used for prints with no impact on printing time.[5] Unlike FFF printers, SLA printers typically print upside down,[5] though this has little tangible effect on the final print. SLA printers can be difficult to operate.[6]

-

A Formlabs Form2 SLA 3D Printer.

-

Form 2 curing equipment. SLA prints require curing following the print process.

Selective laser sintering (SLS)

[edit | edit source]SLS works by fuzing powders together with a laser to create 3D objects.

Uniquely, SLS printers requires no dedicated support structures for complex geometries.[1]

-

An SLS 3D Printer.

References

[edit | edit source]- ↑ a b "3D Pinter Buyers Guide FFF vs SLA vs SLS". LulzBot. 30 August 2019. Retrieved 30 November 2020.

- ↑ "3D Printer Assembly Mentor2". Retrieved 29 November 2020.

- ↑ "The Ultimate Guide to Stereolithography (SLA) 3D Printing (Updated for 2020)". Formlabs. Retrieved 29 November 2020.

- ↑ "3D Printing: A Multitude of Machines & Materials-SLA/DLP Printing – Techbytes". Retrieved 29 November 2020.

- ↑ a b "How to slice 3D objects for the Original Prusa SL1 [updated with video guide]". Prusa Printers. 19 June 2019. Retrieved 29 November 2020.

- ↑ Finnes, Tyler (1 January 2015). "High Definition 3D Printing – Comparing SLA and FDM Printing Technologies". The Journal of Undergraduate Research. Retrieved 29 November 2020.

Printer Specs

Introduction

[edit | edit source]You may have read about how 3D printers can do amazing things in the news, like print houses, cars, or human organs. While these things are possible, they depend on both the technology used by the 3D printer and the skill of the operator. As of 2020 most consumer 3D printers top out at printing high quality plastics at up to a quarter of a meter cubed on the high end.

With that said, there are a number of factors in a 3D printer that can make printing easier, faster, and more enjoyable. Furthermore as a technology seeing slow but steady continued advancement, capabilities of printers continue to improve over time. With the open nature of many printers, those with a deep understanding of the field can push printers beyond their expected capabilities and achieve superior results.

Enclosures & Structure

[edit | edit source]A heated enclosure can assist the printing of certain materials.[1]

Safety benefits

[edit | edit source]3D printer safety is more than what features are built into the printer! Always consult with manufacturer instructions, laws, local experts, and any other resources available to you before operating a 3D printer. |

3D printers with enclosures typically reduce the amount of particles exposed to the operator.[2] Enclosures also help reduce the chance of accidental contact with moving or hot parts.[3]

Computer

[edit | edit source]

3D printers use a built in computer to precisely control internal printer operation. The board containing the computer will determine things like a printer's ability to connect to a network, expansion headers, and what firmware can be run on the printer.[4][5]

3D printer microcontrollers are typically either simple and reliable 8-bit microcontrollers, or more capable and complex 32 bit ones.[6] A more capable controller used with software that leverages it's features can allow the 3D printer to handle more of it's tasks independently of a host computer,[7] as well as potentially operate the 3D printer faster while achieving greater print quality.[8]

Drivers

[edit | edit source]Many 3D printer controller boards include built in drivers, though some use external drivers.[4] High quality drivers can improve motor operation to be more efficient and thus reduce printer noise.[9][10]

Motors

[edit | edit source]Most 3D printers use stepper motors for to move parts with percision.[11]

Rarely, servo motors are used in special 3D printers to allow feedback to control systems.[12][13] However their high cost, increased complexity, and reduced reliability makes stepper motors the typical choice for most 3D printers.[14][15]

Print head

[edit | edit source]

The nozzle used has an impact on print resolution.[16]

Some nozzles are made out of exotic materials like ruby to enhance their durability.[17]

Bed

[edit | edit source]Magnetic plates, flexible beds, and Bed coatings can make them easier to print with, but also require special care to keep them working well.[18][19]

Autoleveling

[edit | edit source]Some 3D printers can probe the print bed prior to printing and autolevel it.[20] This makes setup simpler, and much less tedious.

Heated Bed

[edit | edit source]A heated bed is handy for reducing part warping, a common problem when printing on an unheated bed.[21]

Filament sensor

[edit | edit source]Filament sensors are used to allow the printer to detect jams, empty filament spools, and other quality control features.[22][23]

Camera

[edit | edit source]When used with specialized software, a dedicated camera can create intriguing time lapses of prints.[24]

References

[edit | edit source]- ↑ "Bringing High Temperature 3D Printing To The Masses". Hackaday. 28 October 2020. Retrieved 6 November 2020.

- ↑ "3-D Printer Safety Environmental, Health & Safety". www.rit.edu. Retrieved 6 November 2020.

- ↑ "3D Printer Safety – Environment, Health, and Safety". Retrieved 6 November 2020.

- ↑ a b "32 Bit 3D Printer Board Comparison Chart". 3DAddict. 23 January 2018. Retrieved 29 November 2020.

- ↑ "2020 Best 3D Printer Controller Boards". All3DP. 11 October 2020. Retrieved 29 November 2020.

- ↑ "A 32-bit Boost For Your 3D Printer". Hackaday. 10 May 2019. Retrieved 6 November 2020.

- ↑ "Prusa Unveils New Mini 3D Printer, Shakes Up The Competition". Hackaday. 13 October 2019. Retrieved 6 November 2020.

- ↑ "Why Your Next 3D Printer Should Use a 32 Bit Controller". MechLounge. 10 January 2019. Retrieved 29 November 2020.

- ↑ Bush, Steve (11 June 2019). "TMC2209 - a part number you are going to hear more about in 3D printing (or maybe TMC5160)". Electronics Weekly. Retrieved 29 November 2020.

- ↑ "How to make your 3D printer smart and silent with the TMC2130! – Tom's 3D printing guides and reviews". Retrieved 29 November 2020.

- ↑ "Stepper Motor Mentor2". Retrieved 29 November 2020.

- ↑ "Is It A Stepper? Or Is It A Servo?". Hackaday. 30 April 2016. Retrieved 29 November 2020.

- ↑ Santos, Ramon; James, Justin; Chris, Taylor; Marshall, Stephen; Maalouf, Paul (1 June 2015). "Deltronic Solutions Delta 3D Printer". Mechanical Engineering. Retrieved 29 November 2020.

- ↑ "Stepper Motors vs Servo Motors – re:3D Life-Sized Affordable 3D Printing". Retrieved 29 November 2020.

- ↑ Florian, David. "How to Build a 3D Printer: Stepper Motors". www.drdflo.com. Retrieved 29 November 2020.

- ↑ "3D Equipment duPont-Ball Library". Retrieved 29 November 2020.

- ↑ "Rubies Are A 3D Printer's Best Friend". Hackaday. 30 November 2017. Retrieved 6 November 2020.

- ↑ "How to print on a powder-coated sheet". Prusa Printers. 7 June 2019. Retrieved 6 November 2020.

- ↑ "Improved Flexible Build Plate For SLA Is Ready To Rock". Hackaday. 26 October 2020. Retrieved 6 November 2020.

- ↑ "Prusa Dev Diaries #1: Mesh Bed Leveling". Prusa Printers. 20 September 2019. Retrieved 6 November 2020.

- ↑ "Heating Up A Printrbot's Bed". Hackaday. 16 June 2014. Retrieved 6 November 2020.

- ↑ "The Prusa I3 MK3S And A Tale Of Two Sensors". Hackaday. 8 October 2020. Retrieved 6 November 2020.

- ↑ "Stop Printing Air With A Filament Sensor". Hackaday. 4 March 2017. Retrieved 29 November 2020.

- ↑ "FormerLurker/Octolapse". 5 November 2020. Retrieved 6 November 2020.

Materials

Plastics

[edit | edit source]

FFF 3D printers typically accept a filament of a certain diameter.

Some FFF 3D printers are modified to use pellets for ease of using recycled material.[1]

PLA

[edit | edit source]PLA is a common 3D printing material. It's inexpensive and easy to use, making it a good choice as a starter material for beginners, and a general material for more advanced operators.[2]

Compared to using ABS, a typical FFF printer using PLA should emit less particles.[3]

ABS

[edit | edit source]

ABS is cheap and strong but needs the right environment to print well.[4]

Compared to using PLA, a typical FFF printer using ABS should emit more particles.[3][5] Ventilation should be used when printing ABS.[4]

HIPS

[edit | edit source]HIPS is a good starting material due to its ease of use and because it is not expensive.[6]

PETG

[edit | edit source]PETG prints are externally similar to ABS prints despite their different chemical makeup. PETG is less volatile than ABS, remaining stable under a wider range of printing environments.[2]

PETG can't be directly printed on a glass bed.[2] An intermediate material like tape must be used.[7]

Nylon

[edit | edit source]

Nylon 3D prints are known for being somewhat flexible and durable.[7][8]

Nylon can also be dyed to produce different color materials.[7]

Nylon can be temperamental and difficult to work with.[4]

Flexible

[edit | edit source]Flexible filaments are expensive to buy and temperamental to use, but gives prints unique properties, allowing them to deform slightly.[2] These filaments tend to jam, and are best used on direct drive printers.[4]

Ideal Support Materials

[edit | edit source]

PVA

[edit | edit source]PVA is water soluble, so PVA material melts in water while leaving the primary plastic intact.[4] This makes it ideal for support material when used in a dual extruder or a multi material printer, since supports can be dissolved instead of manually removed.

Composite Materials

[edit | edit source]Composite materials mix a printable material with a material that typically can't be printed, giving it unique properties, as well as unique challenges.

Composite Examples

[edit | edit source]- Magnetic Iron PLA - Can attract strong magnets and rust.[9][10]

- Conductive PLA - Prints are electrically conductive and can carry small currents for simple electronics or to enable parts to trigger touchscreens.[11]

Resins

[edit | edit source]SLA printers use liquid resin, instead of filaments.

These resins can usually be colored with dye.[12][13]

Exotic Materials

[edit | edit source]3D printers geared towards directly printing in exotic materials exist.[14][15]

It is often a better idea to try 3D printing a mold in a conventional material and then using that mold to make the end product.[16][17]

3D printing food in particular has unique challenges, as the food must be printed in a way that avoids contamination and is safe to eat.[18]

-

3D printed jewelry.

-

3D printed cookies.

-

A 3D Printed sugar cube.

Material Storage

[edit | edit source]When possible FFF filaments should be kept in a drybox to avoid contamination of material from humidity and dust.[21] If this is impractical, a dust filter can also be used on the filament feed.[22]

References

[edit | edit source]- ↑ "10 Tips for Converting a 3D Printer to Pellet Extrusion | Make:". Make: DIY Projects and Ideas for Makers. 25 November 2020. Retrieved 30 November 2020.

- ↑ a b c d "3D Printer Filaments: Definitions, Applications, and Tips". Retrieved 6 November 2020.

- ↑ a b "3D Printer Safety – Environment, Health, and Safety". Retrieved 6 November 2020.

- ↑ a b c d e White, Lindsay. "Materials for 3D Printing – build IT @SDSU Library". Retrieved 6 November 2020.

{{cite web}}: Missing|author1=(help) - ↑ "Particles Emitted by Consumer 3D Printers Could Hurt Indoor Air Quality". www.news.gatech.edu. Retrieved 6 November 2020.

- ↑ "Printing Materials – Innovation Studio". Retrieved 6 November 2020.

- ↑ a b c "Closing the Loop On 3D Printing". UCSF Library. 30 November 2017. Retrieved 29 November 2020.

- ↑ Meher, Robin. "Library Guides: 3D Printing at the Library of Engineering and Science: Filament Guide". guides.lib.purdue.edu. Retrieved 29 November 2020.

- ↑ "Magnetic Iron PLA Magnetic 3D Printer Filament". LulzBot. 18 September 2015. Retrieved 6 November 2020.

- ↑ "Iron-filled Metal Composite PLA". ProtoPlant, makers of Proto-pasta. Retrieved 6 November 2020.

- ↑ "Conductive PLA". LulzBot. 18 September 2015. Retrieved 6 November 2020.

- ↑ "Color Kit". Formlabs. Retrieved 30 November 2020.

- ↑ "How Do I Dye Resin 3D Prints? - Easy To Create Custom Colored Resin". 3D Printed Miniatures for Gaming or Display. 31 January 2020. Retrieved 30 November 2020.

- ↑ "CES 2014: 3D food printers create sweets and chocolates". BBC News. 8 January 2014. Retrieved 6 November 2020.

- ↑ "Engineers Create A Titanium Rib Cage Worthy Of Wolverine". NPR.org. Retrieved 6 November 2020.

- ↑ Says, Jobfor778 (7 February 2020). "The beginner's guide to mold making and casting". Prusa Printers. Retrieved 6 November 2020.

- ↑ "Casting Metal Parts And Silicone Molds From 3D Prints". Hackaday. 25 February 2018. Retrieved 6 November 2020.

- ↑ "Maker Faire NY: Cocoa Press Chocolate Printer". Hackaday. 29 September 2018. Retrieved 6 November 2020.

- ↑ Mishan, Ligaya (21 February 2019). "The Secret Ingredient for These Desserts: A 3-D Printer (Published 2019)". The New York Times. Retrieved 29 November 2020.

- ↑ "NASA's 3D Food Printer Will Make Pizza at Amusement Parks". www.vice.com. Retrieved 29 November 2020.

- ↑ "Filament dryboxes and alternative spool holders - not only for MMU2S". Prusa Printers. 26 July 2019. Retrieved 6 November 2020.

- ↑ "Filament Dust Filter Helps Keep Your Print Quality High". Hackaday. 6 September 2020. Retrieved 6 November 2020.

Models

Creation

[edit | edit source]Manual

[edit | edit source]It is possible to design a 3D model from the ground up for 3D printing using standard 3D software.

3D Scanning

[edit | edit source]3D Scanning through techniques such as photogrammetry can be used to duplicate real world objects.[1]

-

A 3D Scanner that photographs objects as they move on a turntable.

-

A less common but quicker scanner type uses a chamber filled with cameras that surround the subject.

Editing

[edit | edit source]Some models, such as those created by 3D scanning, require cleanup before they can be printed.[2]

3D models on a computer can represent things that are impossible to recreate in reality. Thus for a model to be 3D printable, it must represent an actual object, without errors in an object that would cause the interior of the model to not be watertight.[3]

File Formats

[edit | edit source]STL

[edit | edit source]

.stl has become a defacto standard for many 3D printer slicer programs.[4][5]

3MF

[edit | edit source]3MF is an open source format that offers a number of improvements over .stl, such as being more error resistant and including color information.[6][7]

Related Wikibooks

[edit | edit source]References

[edit | edit source]- ↑ "Photogrammetry 2 - 3D Scanning simpler, better than ever!". Prusa Printers. 3 December 2018. Retrieved 6 November 2020.

- ↑ Hoya, Billy. "LSC-North Harris Library Research Guides: Creating 3D Objects using Photogrammetry: Step 3: Viewing, Printing, and Editing". nhresearch.lonestar.edu. Retrieved 29 November 2020.

- ↑ Charlesworth, Sean (19 March 2014). "Bits to Atoms: 3D Modeling Best Practices for 3D Printing". www.tested.com. Retrieved 29 November 2020.

- ↑ Mellinger, Margaret. "LibGuides: 3D printing : 3D Printing Tips". guides.library.oregonstate.edu. Retrieved 29 November 2020.

- ↑ "Art + Design - Tutorial - Preparing 3D Print Files for the Zortrax Printers". art.illinois.edu. Retrieved 29 November 2020.

- ↑ "3MF File Format (3D Printing) – Simply Explained". All3DP. 8 October 2018. Retrieved 29 November 2020.

- ↑ "3MF file format and why it's great". Prusa Printers. 1 November 2019. Retrieved 29 November 2020.

Slicing Software

Slicers

[edit | edit source]A slicer converts a 3D model of an object into layers that a 3D printer can understand.

Many slicers include convenience features. A common example includes printer and material presets.[1] Some FFF slicers include uncommon features that help with complex geometry and print reliability.[2]

SLA slicers produce different support structures from FFF slicers.[3]

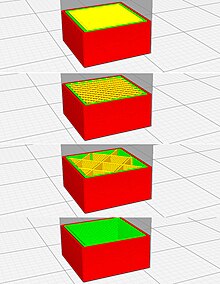

Infill

[edit | edit source]

Infill determines the amount of material on the inside of a print.

A number of creative infill patterns can be used for different purposes, such as 3D infills[4] and gradient infills.[5]

GCode

[edit | edit source]Many 3D printers use GCode for instructions on operation. However not all generated GCode is the same.

There are a number of software packages oriented around GCode. Some software analyses GCode and provides helpful information about a print.[6] GCode post processors can improve print speed and quality.[7] Non-planar GCode can also improve 3D printing results.[8][9]

Slicer features

[edit | edit source]

Layer height

[edit | edit source]Some slicers support variable layer height, allowing for the printer to slow down on detail heavy areas for better quality, and speed up printing for less detailed areas.[10]

Pausing

[edit | edit source]Some slicers allow prints to be paused to allow operators to swap materials partway through, or to add things like magnets to the internals of the print.[10][11]

References

[edit | edit source]- ↑ "PrusaSlicer - Prusa3d.com - 3D printers by Josef Prusa". Prusa3D - 3D Printers from Josef Průša. Retrieved 29 November 2020.

- ↑ "Pathio: New 3D Slicer From E3D". Hackaday. 24 February 2019. Retrieved 29 November 2020.

- ↑ "How to slice 3D objects for the Original Prusa SL1 [updated with video guide]". Prusa Printers. 19 June 2019. Retrieved 6 November 2020.

- ↑ "3D Internal Structure For Better 3D Printed Objects". Hackaday. 10 June 2016. Retrieved 6 November 2020.

- ↑ "Gradient Infill Puts More Plastic Where You Want It". Hackaday. 21 January 2020. Retrieved 6 November 2020.

- ↑ "GCode Analyzer/Visualizer by hudbrog". www.thingiverse.com. Retrieved 6 November 2020.

- ↑ "This GCode Post-Processor Squeezes Lines Into Arcs". Hackaday. 3 November 2020. Retrieved 6 November 2020.

- ↑ "3D Printering: Non-Planar Layer FDM". Hackaday. 27 July 2016. Retrieved 6 November 2020.

- ↑ "makertum/non-planar-layer-fdm". 6 November 2020. Retrieved 6 November 2020.

- ↑ a b "PrusaSlicer 2.2.0 is out! Hollowing, support for 3rd party printers and more!". Prusa Printers. 25 March 2020. Retrieved 6 November 2020.

- ↑ "Change Filament At Z Cura Plugin by rawlogic". www.thingiverse.com. Retrieved 6 November 2020.

Color Printing

Methods of 3D printing in color

[edit | edit source]One way to achieve color 3D printing is to use a multimaterial printer.[1] This requires loading different color materials into the printer, as well as setting up the model(s) and printer software correctly.

One solution to color FFF 3D prints is to simply place markers along the feed of a white filament.[2]

Failing anything, color can be added in post processing steps, such as by painting the print.

Gallery

[edit | edit source]-

A multicolor print made on a FFF printer.

-

A multicolor print made by a printer designed to print in color.

-

A MultiMaterial upgrade for Prusa printers.

-

A color sandstone 3D print.

References

[edit | edit source]- ↑ "3DP – Carnegie Center". Retrieved 29 November 2020.

- ↑ "Sharpie Mount Brings Some Color To Your 3D Prints". Hackaday. 2 November 2020. Retrieved 6 November 2020.

Post Processing

General Post Processing Techniques

[edit | edit source]Sanding is commonly used on 3D prints to smooth prints or remove small imperfections.[1]

Acrylic paint, model paint, nail polish, markers, and spray paint are common ways to add color to a print.[2][3]

Salt annealing and plaster annealing can give parts a unique finish, and alter strength properties of a print.[4][5] Annealing techniques may be effective to improve prints with slight warping.[6]

Process Specific Techniques

[edit | edit source]Post Processing is mandatory for most SLA prints, as extra resin must be removed and desired resin must be hardened.[7][8]

Prints made with ABS plastic can be smoothed with careful application of an acetone vapor.

References

[edit | edit source]- ↑ "Mansfield Library". www.lib.umt.edu. Retrieved 29 November 2020.

- ↑ Jalal, Rita. "Coloring 3D Printed Objects – build IT @SDSU Library". Retrieved 29 November 2020.

- ↑ "3D Print Customization Florida State University Libraries". www.lib.fsu.edu. Retrieved 29 November 2020.

- ↑ "Take This 3D-Print Post-Processing Method With A Grain Of Salt". Hackaday. 27 October 2020. Retrieved 6 November 2020.

- ↑ "Plaster Annealing 3D Prints For Strength". Hackaday. 24 September 2020. Retrieved 6 November 2020.

- ↑ "Final Update: FFF Strength Optimization". Additive Manufacturing blog. 2165. Retrieved 29 November 2020.

{{cite web}}: Check date values in:|date=(help) - ↑ "3D Printering: Wash Parts Better And Make Solvent Last Longer". Hackaday. 6 October 2020. Retrieved 6 November 2020.

- ↑ "customer_v2". support.formlabs.com. Retrieved 6 November 2020.

Maintenance

Introduction

[edit | edit source]3D printers are complex machines that require maintenance to operate efficiently.

Diagrams

[edit | edit source]Axis Alignment

[edit | edit source]

Tension and Backlash

[edit | edit source]

Build Plates

[edit | edit source]

Calibration

[edit | edit source]

References

[edit | edit source]

Applications

Rapid Prototyping

[edit | edit source]When making prototypes, having quick tangible feedback is of great importance for spotting facets of a work which are not immediately clear on paper or in computer models.

One off production

[edit | edit source]When producing just one or a few items, the inherent inefficiencies of 3D printing matter much less, especially if the properties of 3D printed materials are adequate or if the time to begin production is limited (Taking just a few hours or days assuming the model is ready).

Accessibility

[edit | edit source]3D printing can be used to create tactile versions of visual media like artwork or maps for the blind.[1][2]

Logistic stopgap

[edit | edit source]

When supply chains are disrupted in an emergency, local 3D printer owners are able to produce low quantities of vital materials and parts, ensuring a constant, if very small stream of new supplies, while logistical challenges are fixed. This very scenario was seen in the early days of the COVID-19 pandemic, when 3D printer operators made PPE and ventilator parts for hospital staff.[3][4] It is also a strategy employed by some disaster preparedness strategies.[5]

References

[edit | edit source]- ↑ "Please Touch the Art: 3D Printed Masterworks for the Blind". www.vice.com. Retrieved 29 November 2020.

- ↑ Karbowski, Caroline (24 February 2020). "See3D: 3D Printing for People Who Are Blind". Journal of Science Education for Students with Disabilities. doi:10.14448/jsesd.12.0006. Retrieved 29 November 2020.

- ↑ "One Way to Help Strapped Hospitals? Print PPE Using 3D Printers". NPR.org. Retrieved 7 November 2020.

- ↑ Fracassi, Cristian; Romaioli, Alessandro (22 March 2020). "Opinion We Made Copies of Ventilator Parts to Help Hospitals Fight Coronavirus". The New York Times. Retrieved 29 November 2020.

- ↑ "Doomsday Preppers Are Planning to 3D Print Their Way Through the Apocalypse". www.vice.com. Retrieved 29 November 2020.

Development

Progress

[edit | edit source]- Minimum Viable Product achieved on November 29th, 2020.

- Print formatting finished on March 20th, 2021.

This book was created by volunteers at Wikibooks (http://en.wikibooks.org).

What is Wikibooks?

[edit source]

Started in 2003 as an offshoot of the popular Wikipedia project, Wikibooks is a free, collaborative wiki website dedicated to creating high-quality textbooks and other educational books for students around the world. In addition to English, Wikibooks is available in over 120 languages, a complete listing of which can be found at http://www.wikibooks.org. Wikibooks is a "wiki", which means anybody can edit the content there at any time. If you find an error or omission in this book, you can log on to Wikibooks to make corrections and additions as necessary. All of your changes go live on the website immediately, so your effort can be enjoyed and utilized by other readers and editors without delay.

Books at Wikibooks are written by volunteers, and can be accessed and printed for free from the website. Wikibooks is operated entirely by donations, and a certain portion of proceeds from sales is returned to the Wikimedia Foundation to help keep Wikibooks running smoothly. Because of the low overhead, we are able to produce and sell books for much cheaper then proprietary textbook publishers can. This book can be edited by anybody at any time, including you. We don't make you wait two years to get a new edition, and we don't stop selling old versions when a new one comes out.

Note that Wikibooks is not a publisher of books, and is not responsible for the contributions of its volunteer editors. PediaPress.com is a print-on-demand publisher that is also not responsible for the content that it prints. Please see our disclaimer for more information: http://en.wikibooks.org/wiki/Wikibooks:General_disclaimer .

What is this book?

[edit source]This book was generated by the volunteers at Wikibooks, a team of people from around the world with varying backgrounds. The people who wrote this book may not be experts in the field. Some may not even have a passing familiarity with it. The result of this is that some information in this book may be incorrect, out of place, or misleading. For this reason, you should never rely on a community-edited Wikibook when dealing in matters of medical, legal, financial, or other importance. Please see our disclaimer for more details on this.

Despite the warning of the last paragraph, however, books at Wikibooks are continuously edited and improved. If errors are found they can be corrected immediately. If you find a problem in one of our books, we ask that you be bold in fixing it. You don't need anybody's permission to help or to make our books better.

Wikibooks runs off the assumption that many eyes can find many errors, and many able hands can fix them. Over time, with enough community involvement, the books at Wikibooks will become very high-quality indeed. You are invited to participate at Wikibooks to help make our books better. As you find problems in your book don't just complain about them: Log on and fix them! This is a kind of proactive and interactive reading experience that you probably aren't familiar with yet, so log on to http://en.wikibooks.org and take a look around at all the possibilities. We promise that we won't bite!

Who are the authors?

[edit source]The volunteers at Wikibooks come from around the world and have a wide range of educational and professional backgrounds. They come to Wikibooks for different reasons, and perform different tasks. Some Wikibookians are prolific authors, some are perceptive editors, some fancy illustrators, others diligent organizers. Some Wikibookians find and remove spam, vandalism, and other nonsense as it appears. Most Wikibookians perform a combination of these jobs.

It's difficult to say who are the authors for any particular book, because so many hands have touched it and so many changes have been made over time. It's not unheard of for a book to have been edited thousands of times by hundreds of authors and editors. You could be one of them too, if you're interested in helping out.

Wikibooks in Class

[edit source]Books at Wikibooks are free, and with the proper editing and preparation they can be used as cost-effective textbooks in the classroom or for independent learners. In addition to using a Wikibook as a traditional read-only learning aide, it can also become an interactive class project. Several classes have come to Wikibooks to write new books and improve old books as part of their normal course work. In some cases, the books written by students one year are used to teach students in the same class next year. Books written can also be used in classes around the world by students who might not be able to afford traditional textbooks.

Happy Reading!

[edit source]We at Wikibooks have put a lot of effort into these books, and we hope that you enjoy reading and learning from them. We want you to keep in mind that what you are holding is not a finished product but instead a work in progress. These books are never "finished" in the traditional sense, but they are ever-changing and evolving to meet the needs of readers and learners everywhere. Despite this constant change, we feel our books can be reliable and high-quality learning tools at a great price, and we hope you agree. Never hesitate to stop in at Wikibooks and make some edits of your own. We hope to see you there one day. Happy reading!